Self-calibrating type biochemical reaction tank

A biochemical reaction and self-calibration technology, applied in the direction of material electrochemical variables, etc., can solve the problems of small reaction contact surface, low reaction point alignment, slow reaction speed, etc., to avoid cross contamination.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

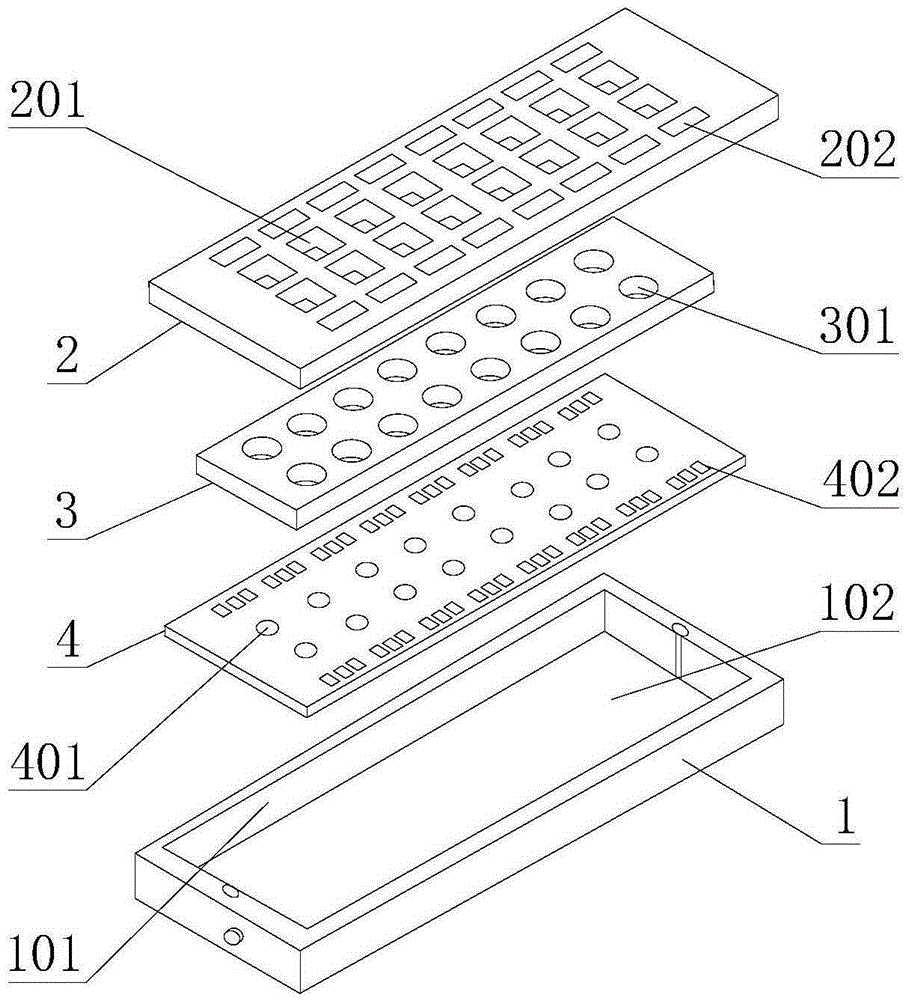

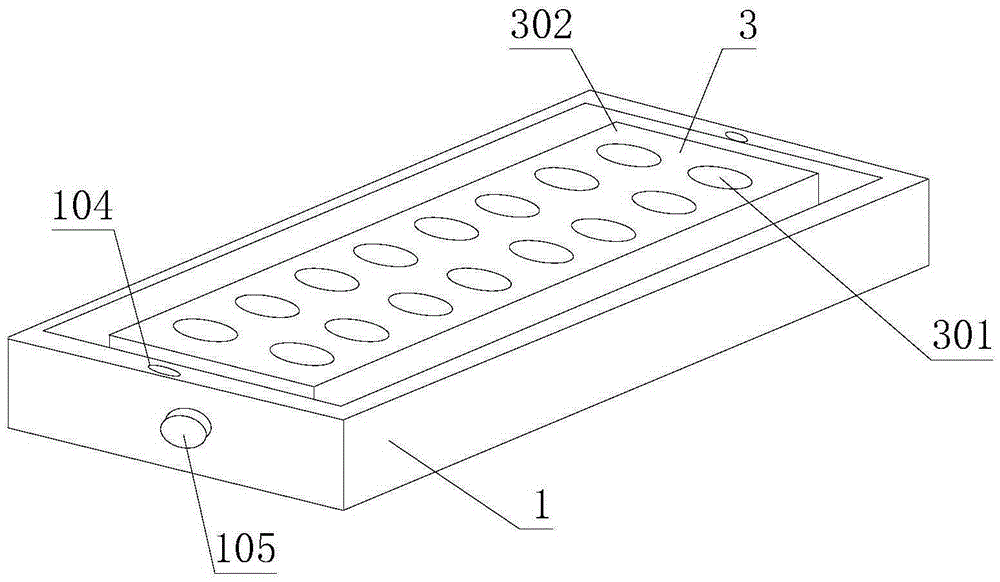

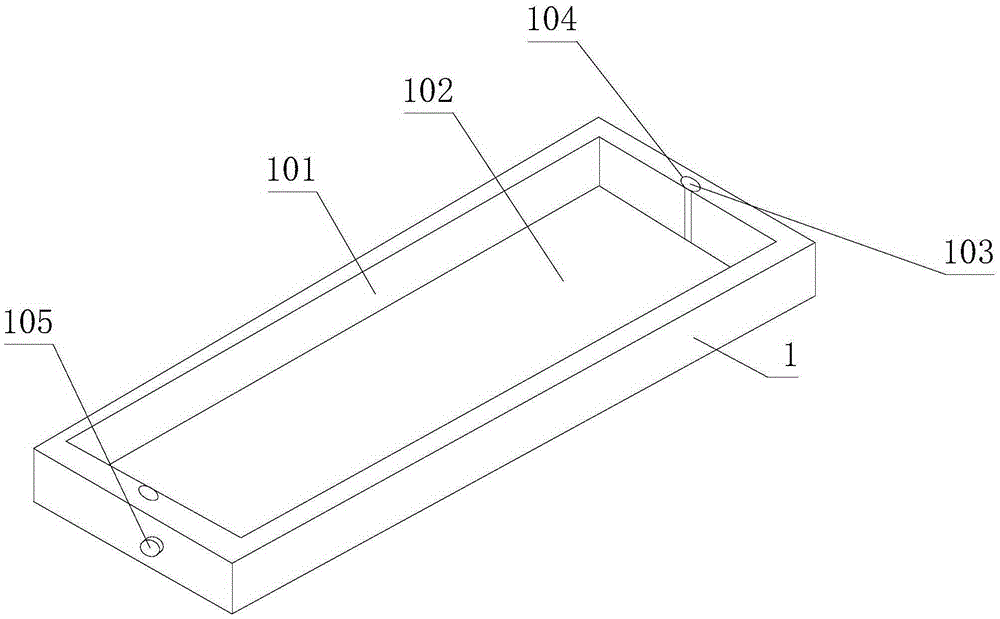

[0024] Such as Figure 1 to Figure 6 As shown, the self-calibrating biochemical reaction pool includes a bottom box 1 and a spacer 3. The bottom box 1 is provided with a chip groove 101, and an upper cover 2 is arranged at the notch of the chip groove 101. Cover 2 can seal the notch of chip groove 101, spacer 3 can be put in the chip groove 101, is provided with a plurality of reaction pools 301 on it, and reaction pool 301 is the hole that runs through spacer 3, and upper cover 2 A plurality of liquid inlet windows 201 and a plurality of electrical connection windows 202 are provided, and the liquid inlet windows 201 correspond to the reaction pools 301 one by one, and a lifting plate 102 is arranged at the bottom of the chip groove 101, and the size of the lifting plate 102 is the same as The chip groove 101 cooperates, and the two corresponding side ends of the lifting plate 102 are all provided with a bar-shaped toothed bar 103, the bar-shaped toothed bar 103 is perpendicu...

Embodiment 2

[0031] Such as Figure 7 to Figure 9 As shown, the structure of this embodiment is basically the same as that of Embodiment 1, the difference is that one side of the upper cover 2 is hinged to the bottom box 1, and a buckle 203 is provided on the opposite side of the side, and a buckle 203 is arranged on the buckle 203 There is a spring piece 204 protruding in an arc shape, and a buckle groove 108 is provided at a position corresponding to the buckle 203 on the bottom box 1 . The upper cover 2 of the device is hinged with the bottom box 1, that is, the upper cover 2 is flipped open and closed, and the other side is a buckle 203. When the upper cover 2 needs to be fixed, the buckle 203 is inserted into the buckle groove 108, and the buckle 203 And the size of the spring sheet 204 is slightly larger than the buckle groove 108, so that the buckle 203 can be pressed into the buckle groove 108 after the spring sheet 204 shrinks. Because the spring sheet 204 presses the buckle groov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com