Capacitive touch sensor having patterned microstructure array

A technology of tactile sensor and microstructure array, which is applied in the direction of instruments, measuring force, measuring devices, etc., can solve the problem that the sensitivity does not reach the precision detection of small force, achieve good flexibility, high sensitivity, and improve the effect of force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with drawings and embodiments.

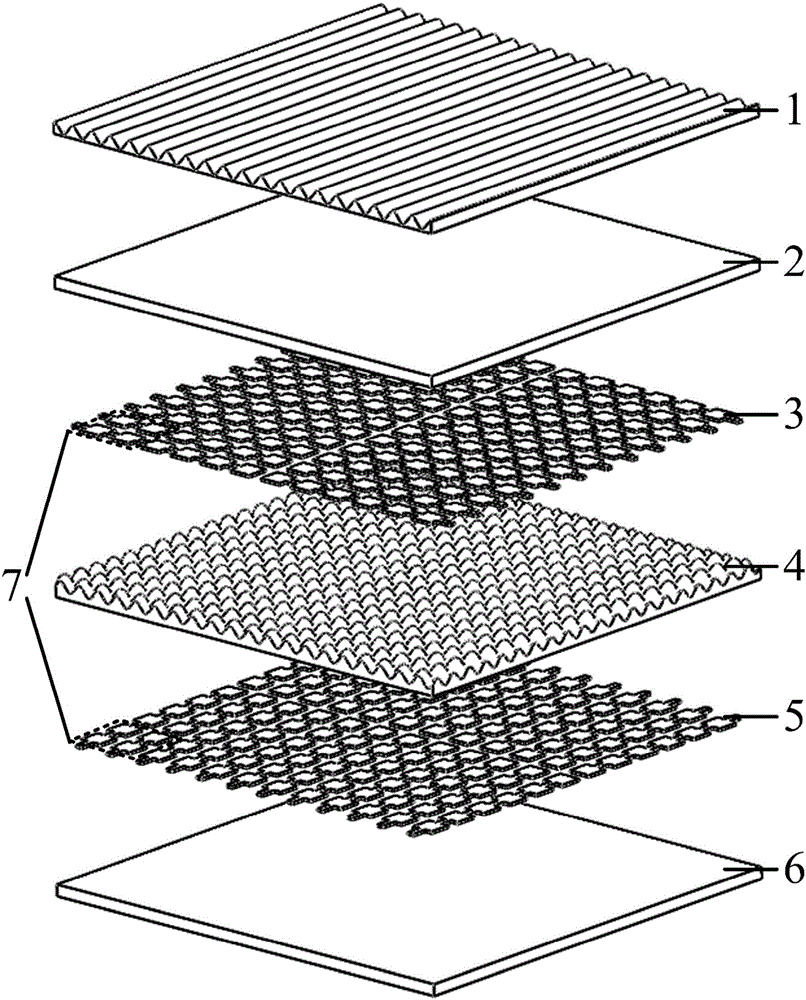

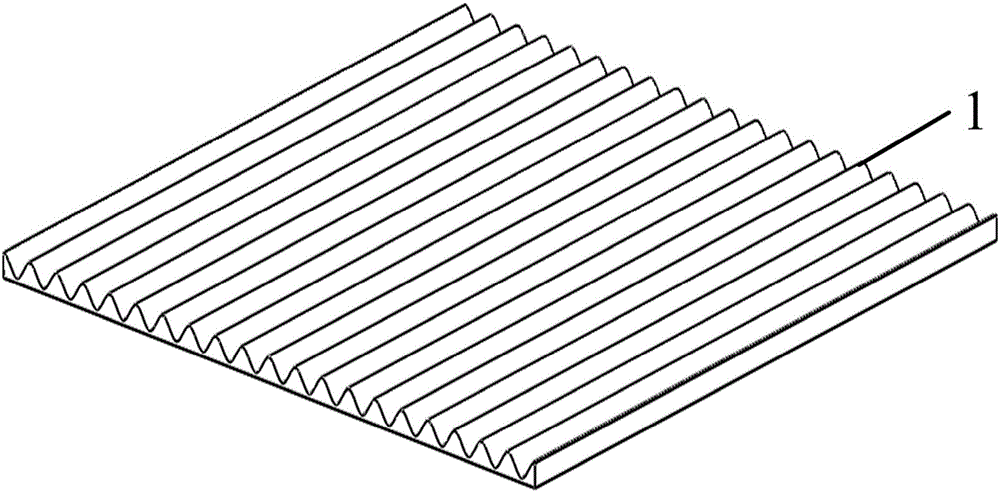

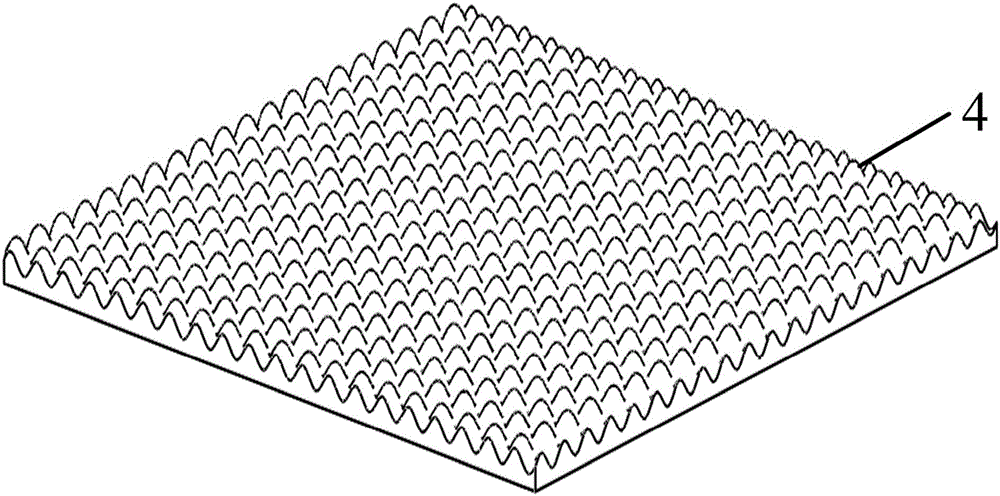

[0031] Such as figure 1 , Figure 8 , Figure 9 As shown, the capacitive touch sensor of the present invention is mainly composed of fingerprint-like surface micro-protrusions 1, upper-layer capacitive electrode substrate 2, upper-layer capacitive electrode 3, two-dimensional sinusoidal micro-protrusion dielectric layer 4, lower layer The capacitive electrode 5 and the lower capacitive electrode substrate 6 are closely stacked, and have multi-dimensional force measurement capability.

[0032] Among them such as figure 1 As shown, the fingerprint-like surface micro-protrusion 1 is used to receive external force stimulation, the upper capacitive electrode base 2 and the lower capacitive electrode base 6 are used as structural supports, and the upper capacitive electrode 3 and the electrode pole pieces on the lower capacitive electrode 5 are connected in a positive dire...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| The average thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com