High-sensitivity quick response heat flux sensor

A heat flow sensor and fast response technology, applied in the field of sensor measurement, can solve the problem that the heat flow sensor cannot quickly respond to small heat flow, etc., and achieve the effects of convenient structure, fast response speed and convenient installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

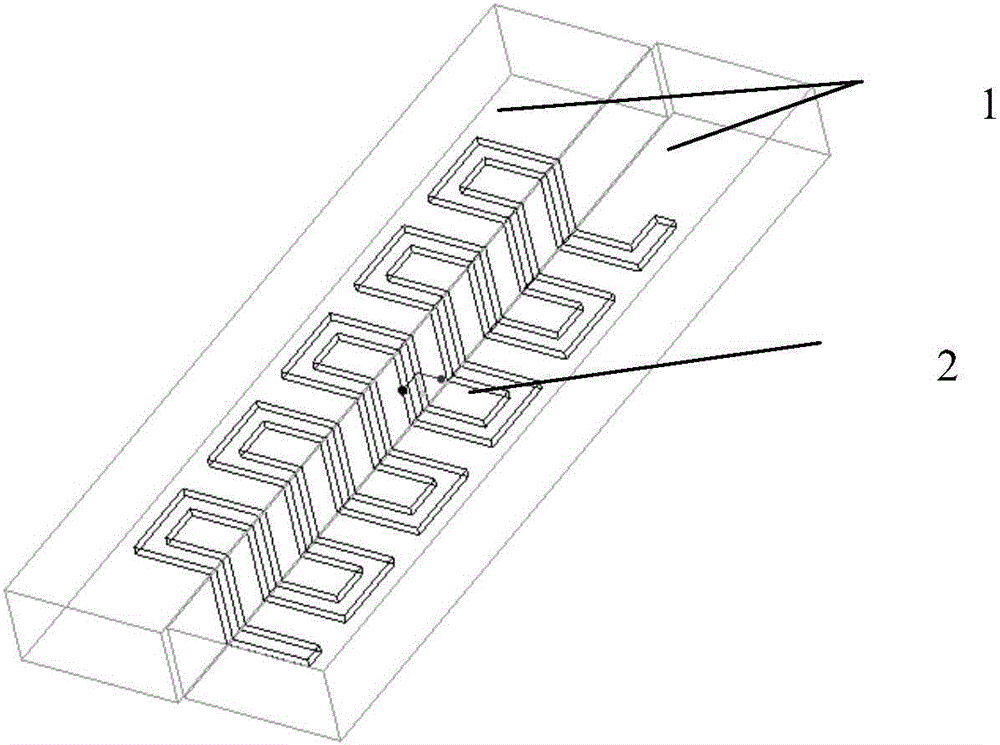

[0038] see figure 1 , the heat flow sensor uses very thin (less than 0.03mm) constantan foil to make zigzag lines (2) of specified size, and copper-plates the prepared lines (2) according to regular divisions, and then the lines formed on the lines The "copper-constantan" and "constantan-copper" thermocouple junctions are regularly arranged on both sides of the surface of the thin film thermal resistance material, forming a thermopile that can sense the temperature difference on both sides of the thermal resistance surface, thereby measuring the incident heat flow.

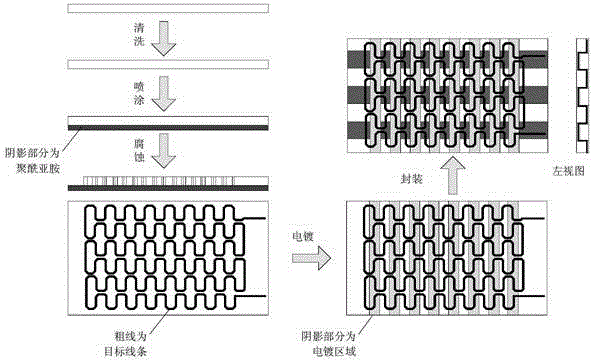

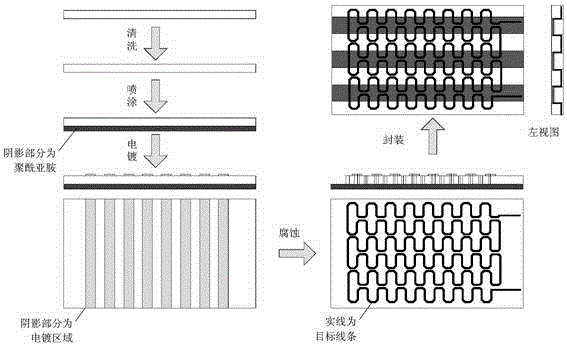

[0039] The key process of the present invention is to make constantan foil copper-plated lines, and the specific process can be realized by two kinds of process routes, the first route is as follows: figure 2 , including the following steps:

[0040] (1) Design the line graph according to the sensitivity index of the sensor, and the sensitivity affects the number n of twists and turns of the line on the equal ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com