Garbage low-temperature pyrolysis furnace combustion-supporting device

A low-temperature pyrolysis and garbage technology, applied in the direction of incinerators, combustion types, combustion methods, etc., can solve the problems of slow carbonization pyrolysis, easy extinguishment, low operating cost, etc., and achieve faster pyrolysis speed and less extinguishment , the effect of low operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

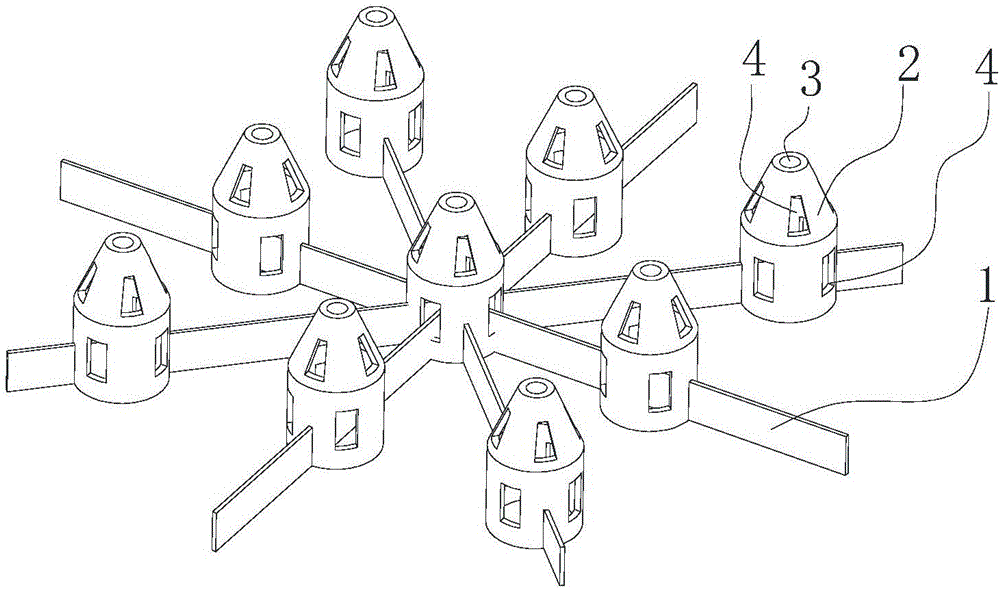

[0011] Such as figure 1 As shown, the combustion-supporting device of the garbage low-temperature pyrolysis furnace of the present invention includes a garbage support frame 1 and a hollow cone 2. The garbage support frame 1 is installed in the garbage pyrolysis furnace, and the garbage support frame 1 is uniformly arranged according to the size of the garbage pyrolysis furnace 3 to 30 hollow cones 2.

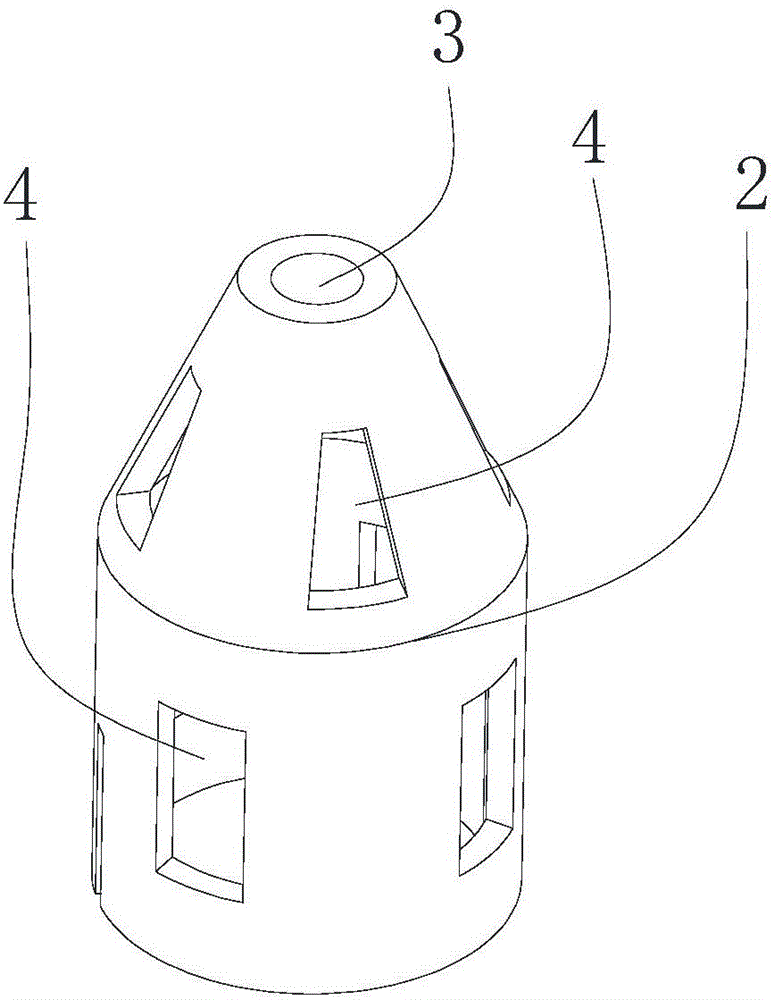

[0012] Each hollow cone 2 has basically the same structure, see figure 2 As shown, the bottom of the hollow cone 2 is open, the cone top of the hollow cone 2 has a ventilation hole 3 that runs through the bottom opening, and the surface of the hollow cone 2 has a ventilation hole 4 that runs through the bottom opening.

[0013] The garbage support frame 1 of the present invention is composed of multiple horizontally arranged and intersecting rods fixedly connected. The intersection point is located in the middle of each rod, and a hollow cone is installed at the intersection....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com