Device for improving Rankine cycle heat efficiency

A Rankine cycle and thermal efficiency technology, applied in steam engine devices, machines/engines, mechanical equipment, etc., can solve the problems of reducing the thermal efficiency of the Rankine cycle and losing the heat energy of exhausted steam

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

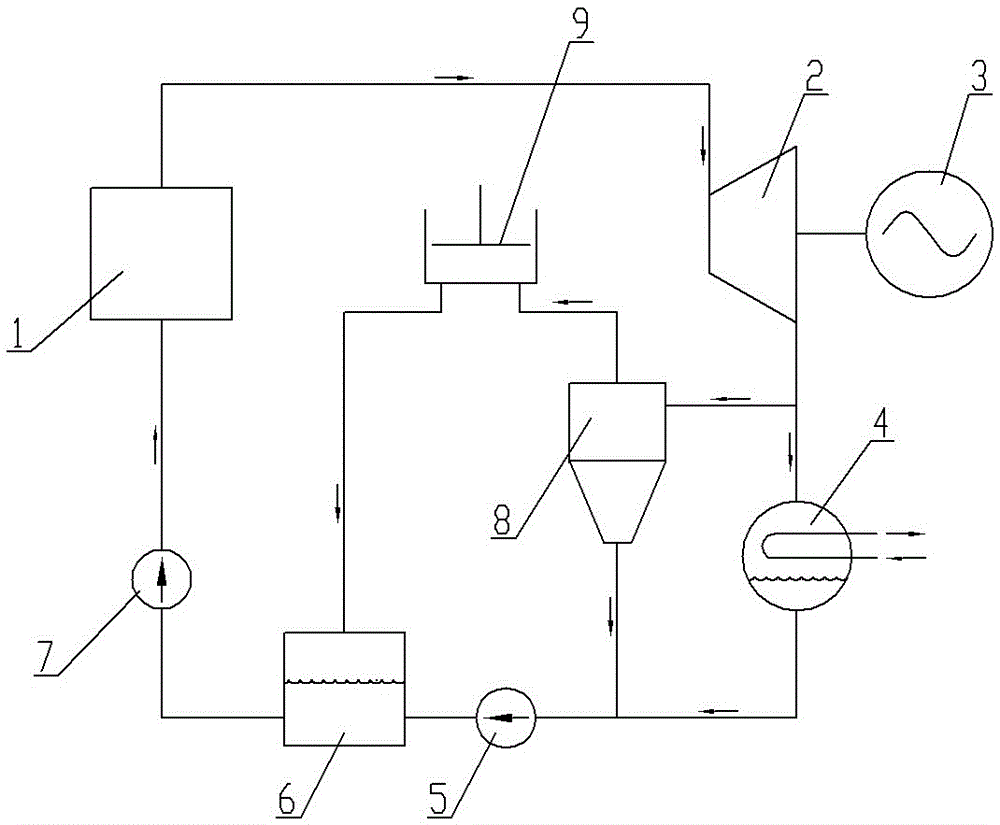

[0007] Such as figure 1 As shown, the present invention comprises a boiler 1, a steam turbine 2, a generator 3, a condenser 4, a circulation pump 5, a mixing tank 6, a feed water pump 7, a vapor-liquid separator 8, and a pressurizer 9, wherein the boiler 1 is an energy Conversion equipment, input energy to heat liquid to generate steam; steam turbine 2 is a device that converts steam heat energy into mechanical energy and drives generator 3 to generate electricity; condenser 4 is a cooling device for exhaust steam, and the exhaust steam is cooled into liquid under the action of cooling medium; Circulation pump 5 provides power for working medium circulation; mixing water tank 6 liquid heating and storage equipment, mixed with steam to directly heat liquid; feed water pump 7 provides power for working medium circulation; vapor-liquid separator 8 plays the role of steam and liquid separation; pressurizer 9 is steam boosting and heating equipment; the inlet of boiler 1 is connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com