Mortise lock

A technology for mortise locks and deadbolts, which is applied to building locks, non-mechanical transmission-operated locks, buildings, etc. It can solve problems such as unfavorable intelligent monitoring, cumbersome operation, and complex structure, and achieve improved product appearance and simplified operation steps. , the effect of small shape restrictions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

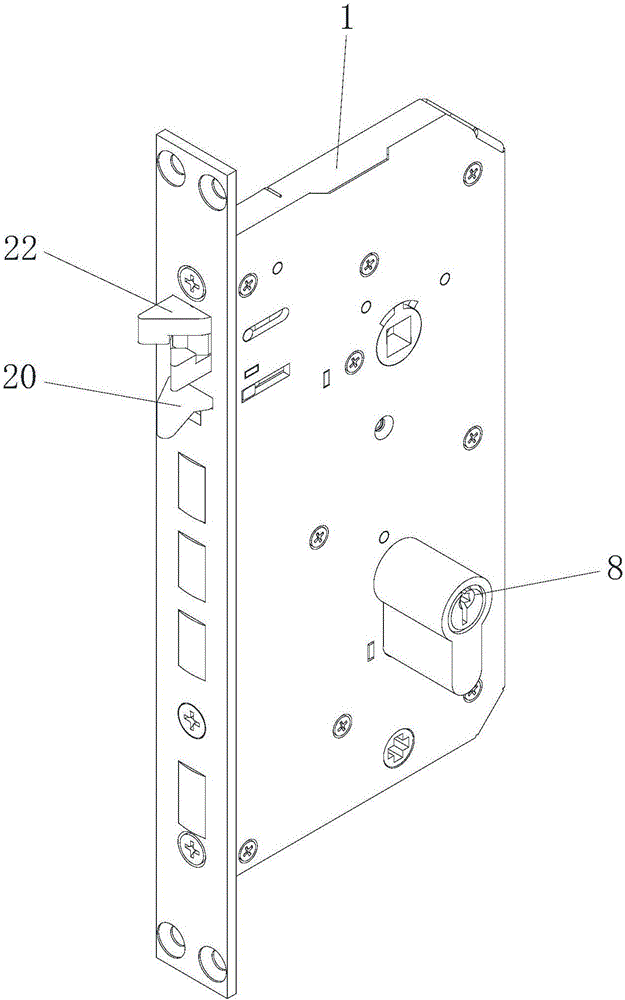

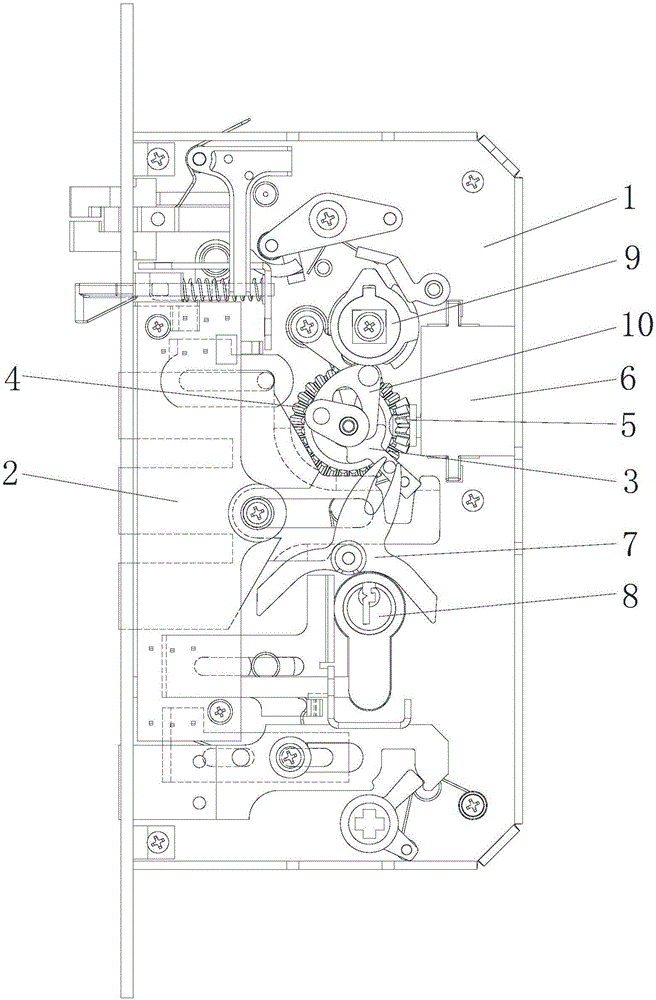

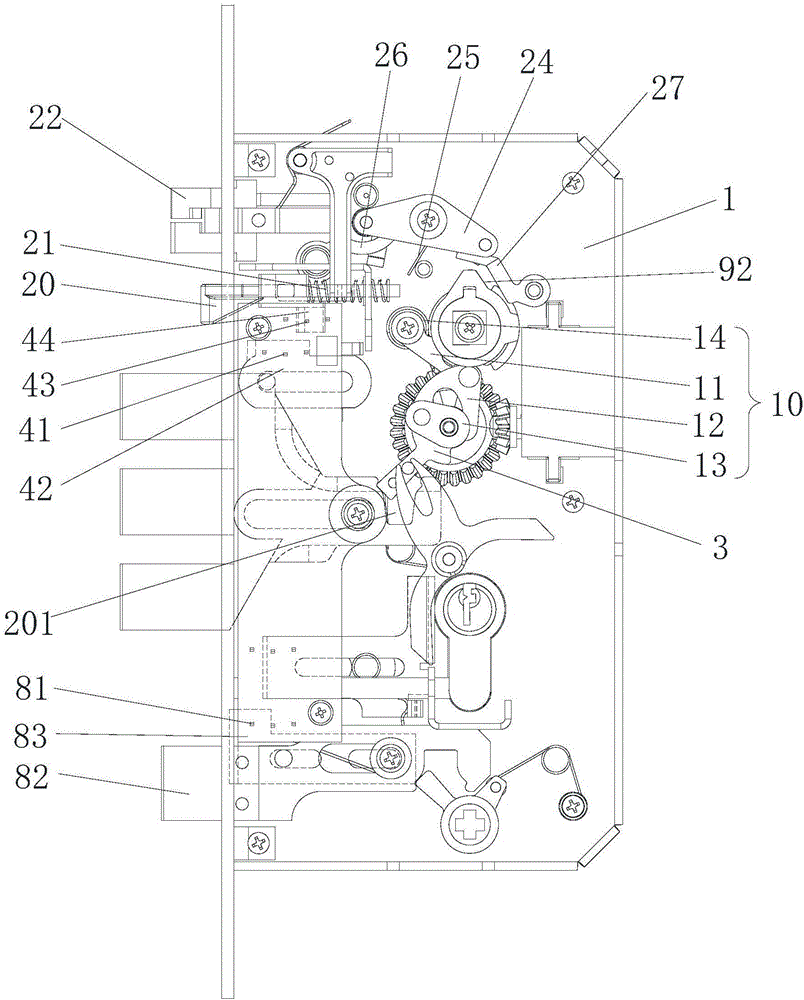

[0036] Please refer to figure 1 -, figure 2 and Figure 8 As shown, the present invention provides a mortice lock, comprising: a housing 1, a main deadbolt 2, a deadbolt rotary block 3, a first bevel gear 4, a second bevel gear 5, a motor 6, a key pick 7 and a lock Core 8.

[0037] The main lock tongue 2 is slidably disposed in the housing 1 . One end of the lock tongue rotating block 3 is rotatably arranged in the housing 1 , and the other end cooperates with the main lock tongue 2 to push the main lock tongue 2 to slide. The first bevel gear 4 is rotatably arranged in the housing 1 . The first bevel gear 4 has a pushing portion 401 cooperating with the deadbolt rotary block 3 for pushing the deadbolt rotary block 3 to rotate. The second bevel gear 5 meshes with the first bevel gear 4 . The motor 6 is connected to the second bevel gear 5 to drive the second bevel gear 5 to rotate. The key pick piece 7 is rotatably arranged in the housing 1 , and the key pick piece 7 i...

Embodiment 2

[0056] Please refer to Figure 14-17 As shown, the difference between the present embodiment and the first embodiment is that the structures of the handle turning block 9 and the bolt turning block 3 are different from the first embodiment. In this embodiment, the handle turning block 9 directly cooperates with the lock bolt turning block 3 to drive the lock bolt turning block 3 to rotate without transmission through the transmission member 10 . The handle turning block 9 has a hook portion 93, and the dead bolt turning block 3 has an elongated portion 33, and the hook portion 93 cooperates with the elongating portion 33 to control the rotation of the dead bolt turning block 3, that is, the hook The rotation of the part 93 can control the rotation of the deadbolt turning block 3 to pull the main deadbolt 2 back into the housing 1 .

[0057] The handle turning block 9 has a door outer rotating part and a door inner rotating part, the door outer rotating part is used for connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com