Automatic covering device for cover plates of wire drawing trolley trench

An automatic covering and ditch technology, applied in buildings, artificial islands, industrial buildings, etc., can solve the problems of hidden safety hazards of production operators, affecting safe production, falling and bumping limbs, etc., to achieve convenient and flexible installation, ensure safe production, and automation high degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

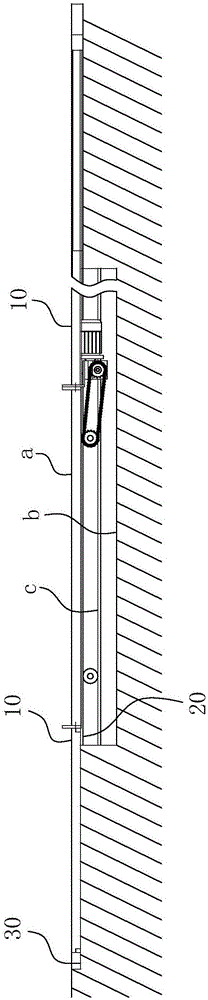

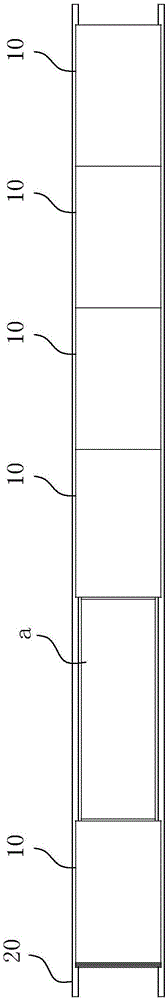

[0024] For ease of understanding, combined here Figure 1-5 Concrete implementation structure and workflow of the present invention are further elaborated as follows:

[0025] The concrete implementation structure of the present invention can refer to Figure 1-5 As shown, on the basis of the original ground trench b with a certain depth arranged on the bottom of the factory building, as well as the track c and the transport trolley a arranged at the ground trench b, the two ends of the traveling direction of the transport trolley a are namely Figure 1-2 The left and right ends shown are respectively arranged with a left cover assembly and a right cover assembly. The structure of the left cover plate assembly and the right cover plate assembly should be arranged symmetrically along the transport trolley a, so as to complete the telescopic covering effect on the notches of the ground groove b at both ends of the transport trolley a. exist Figure 1-2 In the shown structure,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com