Self-restoration single-action type hydraulic cylinder

A single-acting, hydraulic cylinder technology, applied in the direction of fluid pressure actuators, etc., can solve the problems of increasing equipment cost, increasing equipment weight, power loss, etc., and achieve the effect of flexible reset and simple appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

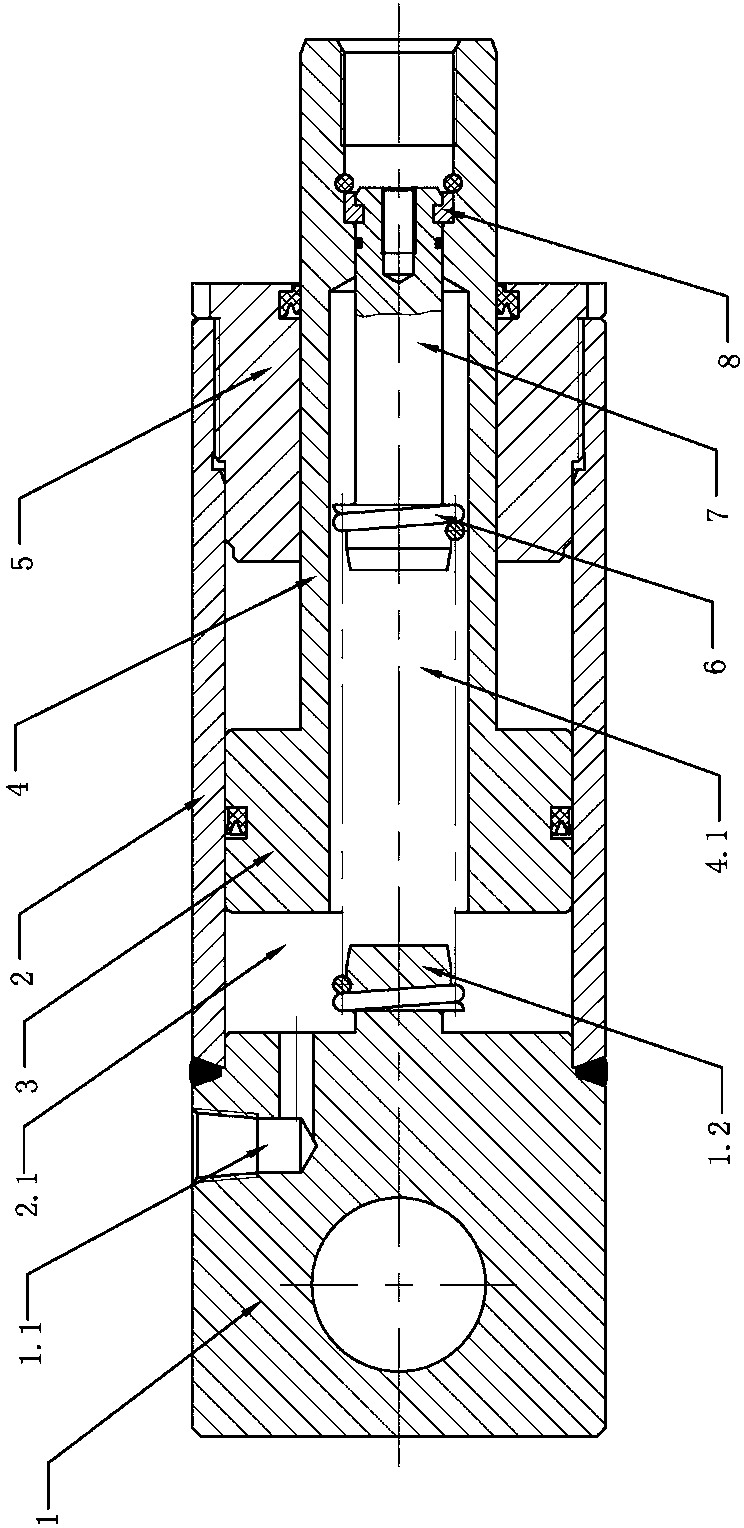

[0010] Such as figure 1 As shown, a self-resetting single-acting hydraulic cylinder includes a cylinder bottom 1, a cylinder body 2, a piston 3, a piston rod 4 and a cylinder head 5. The cylinder bottom 1 is welded to one end of the cylinder body 2, and the cylinder head 5 is installed on the cylinder body 2 At the other end, the piston 3 is set in the cylinder body 2, and one end of the piston rod 4 extends into the cylinder body 2 through the cylinder head 5 to connect with the piston 3, and an oil chamber 2.1 is formed between the piston 3 and the cylinder bottom 1 in the cylinder body 2 , an oil delivery hole 1.1 is provided on the cylinder bottom 1 to communicate with the oil chamber 2.1; it is characterized in that it also includes a spring 6 and a pull rod 7, and a fixing part 1.2 is arranged on the inner bottom surface of the cylinder bottom 1, corresponding to the fixing part 1.2 on the piston rod 4 is provided with a central hole 4.1, and the pull rod 7 is installed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com