Novel safety injection syringe

A safety syringe, a new type of technology, applied in the field of new safety syringes, can solve the complex injection environment (injection into the skin, subcutaneous, intramuscular, tissue or organ, nerve plexus, intravascular, sheath cavity, joint cavity, In the bone, the retraction of the needle seat cannot be realized, and the residual amount of the drug is increased, so as to avoid infection and spread diseases, simple structure, and shielding of the needle tip.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

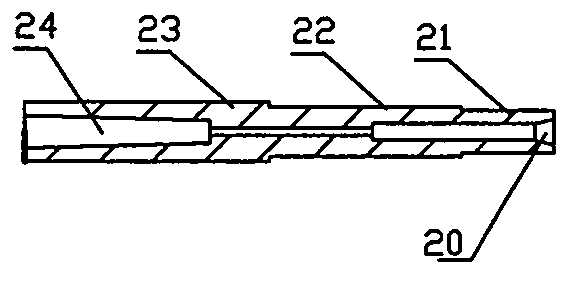

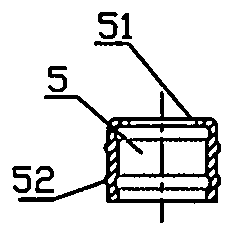

[0026] Depend on figure 1 It can be seen that the novel safety syringe of the present invention is composed of: a sheath 0, a needle tube 1, a needle seat 2, an adsorption pad 3, a damping ring 4, a piston 5, a front plug 6, a push rod 7, and an outer cylinder 8. The sheath 0 can be set on the surface of the cone head at the front end of the outer cylinder 8 to protect the cutting edge of the needle tube from being damaged; the needle tube 1 is a tubular structure made of stainless steel, with a sharp cutting edge 11 at one end, and the adsorption pad 3 is made of paper or cotton and other materials with hygroscopic properties, the damping ring 4 is a ring-shaped object made of elastic plastic material, the needle seat 2 is a cylindrical structure with a through hole in the center, and the piston 5 is made of plastic material A tubular structure with a certain elasticity; the push rod 7 is a hollow tubular structure, and the outer cylinder 8 is hollow tubular, and they are ass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com