A reinforcement system and construction method for improving the bearing capacity of concrete structures

A technology of concrete structure and bearing capacity, applied in bridge reinforcement, construction, bridge construction, etc., can solve the problems of high external cable strength, lack of economic angle, low structural bearing capacity improvement, etc., to achieve high comprehensive economic benefits, adjustment and maintenance. Convenience and the effect of improving the carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The specific implementation of the present invention will be described in detail below in conjunction with the accompanying drawings and specific examples, but this does not constitute a limitation to the protection scope of the claims of the present invention.

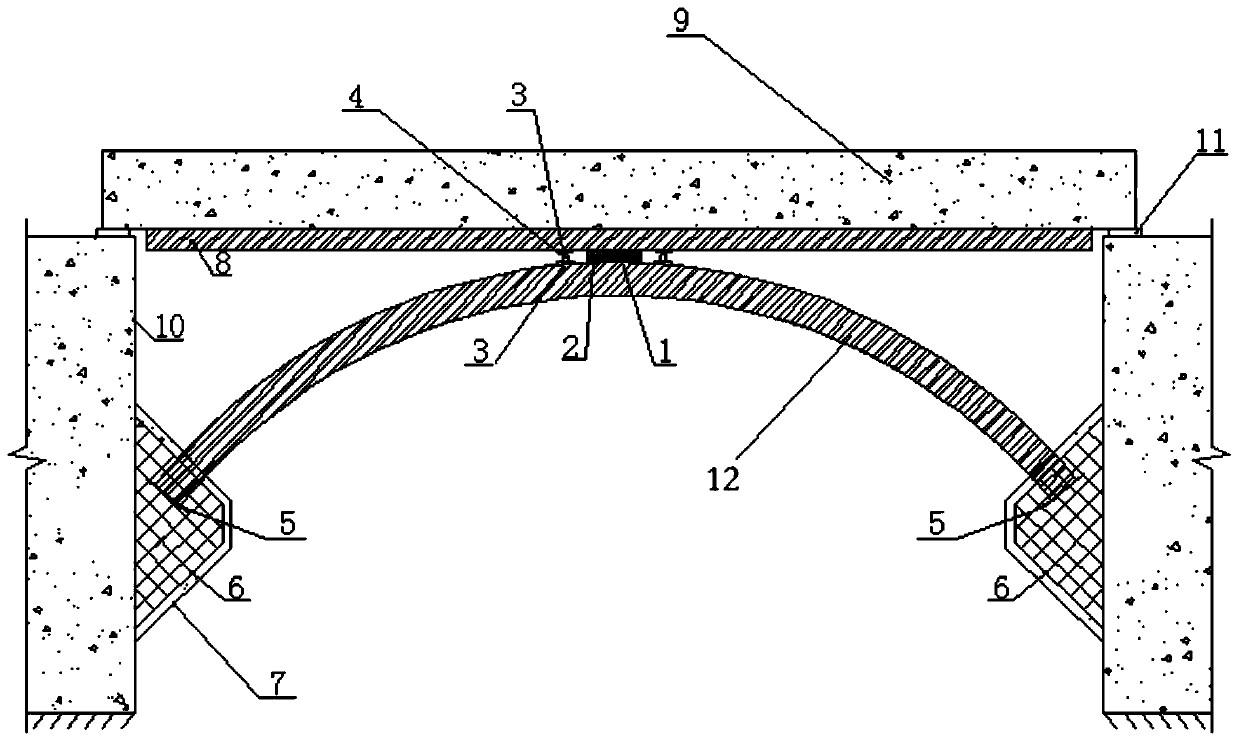

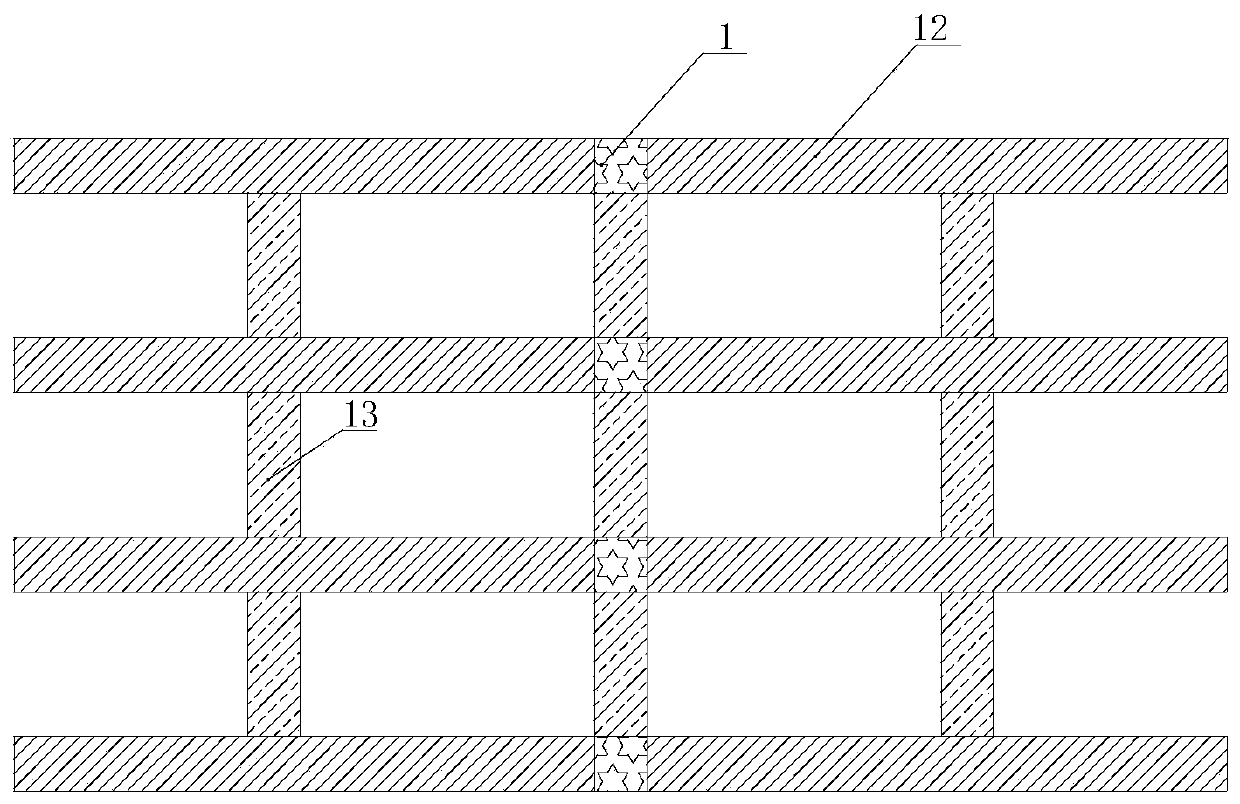

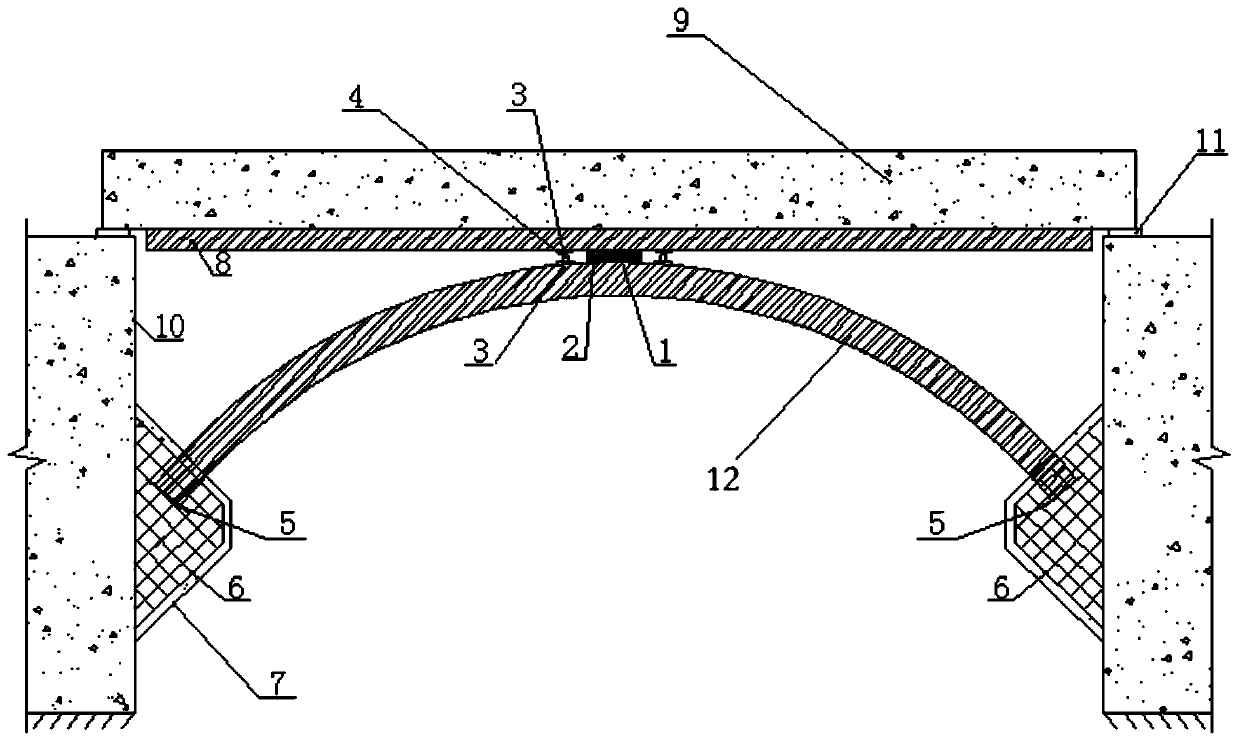

[0041] A reinforcement system for improving the bearing capacity of a concrete structure, comprising a support 1, a support pad 2, an arch ring 12, an arch foot 7 and a steel beam 8; the steel beam 8 is connected to the bottom surface of the main beam 9 of the reinforced structure, The support pad 2 is placed on the top of the arch ring 12, the support 1 is placed on the support pad 2, and the top of the support 1 is connected to the bottom surface of the steel beam 8; the two ends of the arch ring 12 are respectively connected to the reinforced structure through the arch foot 7 Concrete structures 10 on both sides of the main beam 9. Both ends of the reinforced structure main beam 9 are respectively connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com