Metal alloy material for self repair of asphalt pavement and application of metal alloy material

A metal alloy and asphalt pavement technology, which is applied in the field of metal alloy materials, can solve the problems of non-continuous asphalt pavement repair and limited number of asphalt pavement repairs, and achieve the effect of convenient self-repair operation, favorable laying and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Embodiment 1 discloses a metal alloy material for asphalt pavement self-repair, the metal alloy material is martensitic steel; the metal alloy material is deformed under the action of external force, and the deformed metal alloy material is subjected to electrical, magnetic or thermal Scan until its temperature exceeds the first preset temperature, and after removing the electric, magnetic or thermal scanning, the metal alloy material returns to the shape before deformation; the metal alloy material is a titanium-based alloy, Ti-Nb-based; the metal alloy material is a strip or wire shape. Wherein, the first preset temperature is the martensitic transformation temperature of the metal alloy material.

[0033] Specifically, the deformation range of the metal alloy material is 0-10%.

[0034] Specifically, the length of the metal alloy material is 0.01-30m, for example: 0.05m, 0.5m, 1.9m, 5.8m, 12m, 19m, 25m or 29m, etc., and the maximum diameter of the cross-section of t...

Embodiment 2

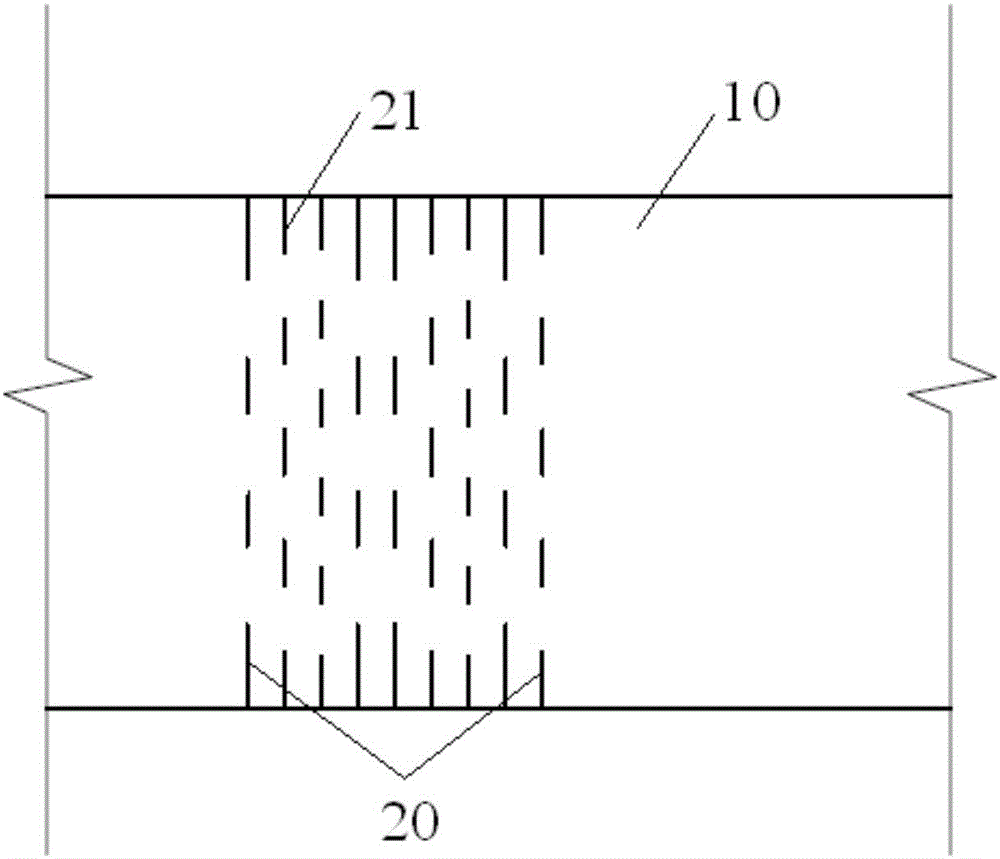

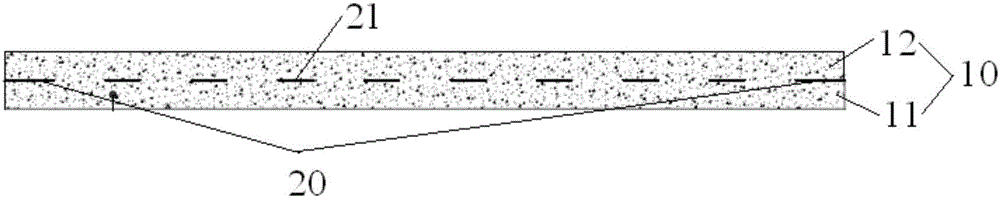

[0037] Such as figure 1 and figure 2 As shown, this embodiment discloses a self-repairable asphalt pavement, including: an asphalt mixture layer 10, including a first asphalt mixture layer 11 and a second asphalt mixture laid on the first asphalt mixture layer 11 The layer 12 ; the metal alloy layer 20 is laid flat in the asphalt mixture layer 10 , including a plurality of the above-mentioned metal alloy materials 21 , and there is a gap between adjacent metal alloy materials 21 .

[0038] Specifically, the weight ratio of the metal alloy layer is 0.2-2, such as 0.3%, 0.8%, 1.2%, 1.6% or 1.9%; in the vertical direction of the length direction of the metal alloy material, the metal alloy The distance between materials is 0.01-0.1 m, such as 0.03 m, 0.05 m, 0.06 m, 0.075 m or 0.09 m.

[0039] Specifically, the metal alloy layer includes multiple rows of metal alloy materials, and the multiple rows of metal alloy materials are along the first direction (ie figure 1 The horizo...

Embodiment 3

[0042] When the asphalt pavement deforms, the metal alloy material in the deformed asphalt pavement also deforms. This embodiment discloses a method for repairing the asphalt pavement in Embodiment 2. Electric, magnetic or thermal scanning is performed at the deformed area of the asphalt pavement, so that the temperature of the metal alloy material in the deformed area exceeds the first preset Temperature, the martensite phase of the metal alloy material disappears, and gradually transforms into the austenite phase. After removing the electric, magnetic or thermal scanning, the metal alloy material changes from the austenite phase to the martensite phase, and recovers before deformation. At the same time, the metal alloy material drives the deformed area of the asphalt pavement to restore the shape before deformation.

[0043] During specific implementation, specific implementation devices for electrical, magnetic or thermal scanning can be specifically selected according ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com