Super-hydrophobic functional material and preparation method thereof

A functional material and super-hydrophobic technology, applied in the field of textile materials, can solve the problems of affecting the wearing comfort of clothing materials, hindering the sweat out, and feeling stiff, so as to maintain crispness and appearance, ensure breathability, and prevent contamination. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0037] According to a preferred embodiment of the present invention, the preparation method of the superhydrophobic functional material comprises the following process steps:

[0038] (1) Fabric pretreatment to remove wax, oil and surfactants that may remain on the material.

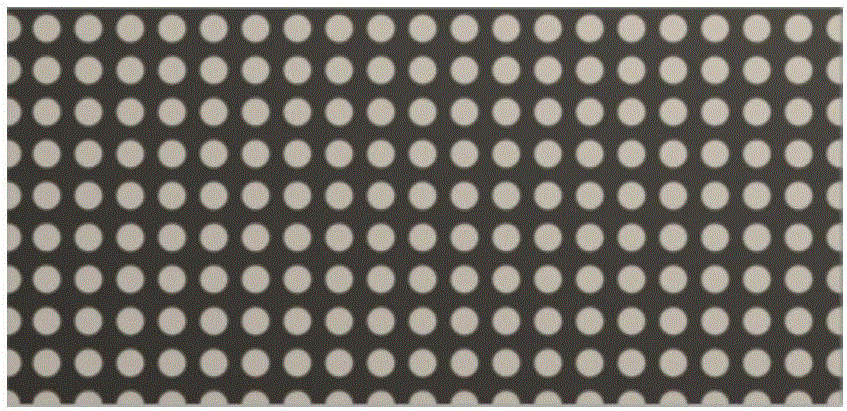

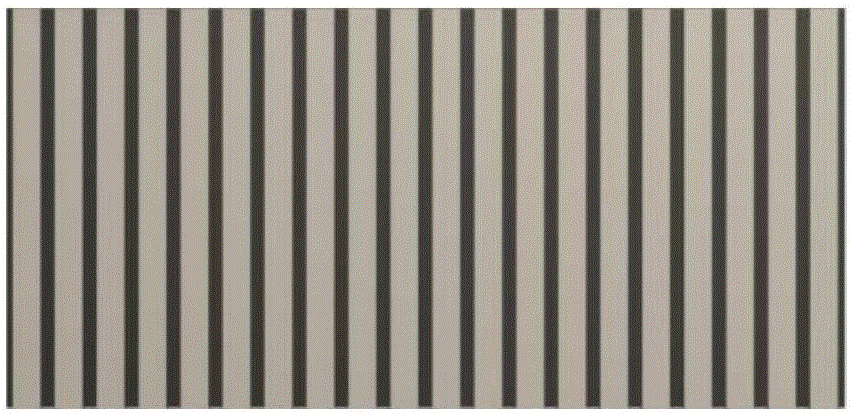

[0039] (2) Prepare superhydrophobic lattices or ribbons by dot printing method or continuous imprinting method.

[0040] (3) Circulating hot air drying.

[0041] Preferably, the fabric pretreatment process uses Na 2 CO 3 : 5%, temperature 40-45°C, time 15-20min, liquid retention rate 50%; then dry at 100°C for 2min.

[0042] Preferably, the material is coated at room temperature.

[0043] Preferably, the temperature of the circulating hot air drying is 70-100° C., and the time is 1-2.5 minutes.

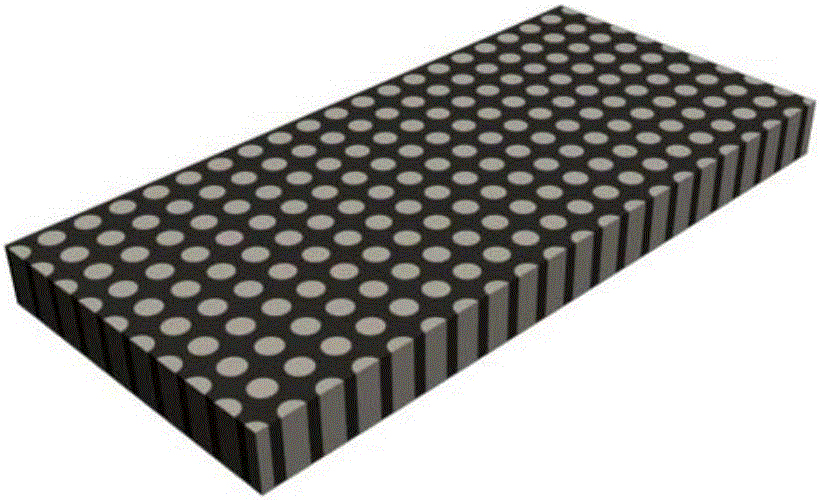

[0044] According to a preferred embodiment of the present invention, the super-hydrophobic functional material is a chemical method, using a super-hydrophobic agent to draw a specific pattern with a hydroph...

Embodiment 1

[0064] Pre-treat high-count pure cotton fabrics to remove waxes, oils and surfactants that may remain on the material.

[0065] Using nano-silica as an additive, prepare a super-hydrophobic working solution with a concentration of 70g / l and a pH value of 6-6.5, put it into a liquid storage tank, and print on a dot printing device.

[0066] Put it into an oven and dry at 100°C for 2 minutes to obtain a super-hydrophobic functional pure cotton fabric.

Embodiment 2

[0068] The natural ramie fabric is pretreated to remove waxes, oils and surfactants that may remain in the material.

[0069] Using nano-zinc oxide as an additive, prepare a super-hydrophobic working solution with a concentration of 70g / l and a pH value of 6-6.5, put it into a liquid storage tank, and print on a continuous imprinting device.

[0070] Put it into an oven and dry at 100°C for 2 minutes to obtain a superhydrophobic functional ramie fabric.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com