Blast furnace replacement large sleeve drawing device

A technology for extracting devices and large sets, applied in tuyere and other directions, can solve the problems of blast furnace tuyeres, large sets of burn-through, difficulty in replacing large sets of devices, affecting safety and production, etc., to achieve small size, reduce spare parts cost, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to enable those skilled in the art to better understand the solution of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

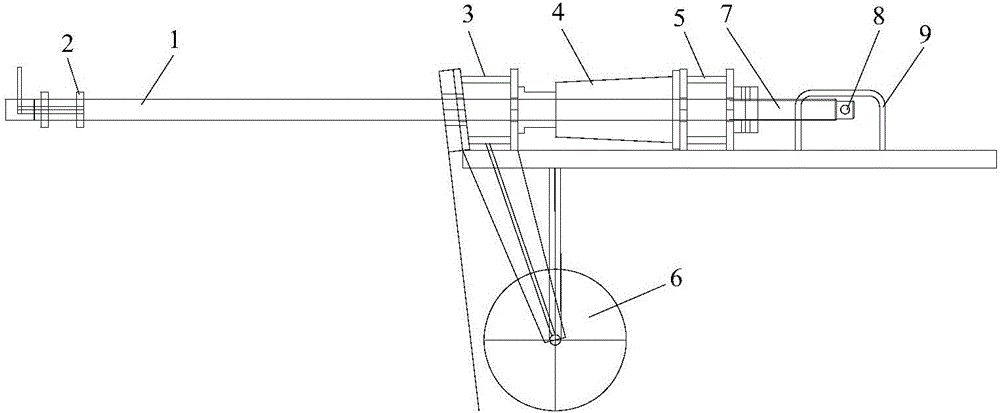

[0040] In a specific embodiment, the present invention provides a large set extraction device for blast furnace replacement. Please refer to figure 1 and figure 2 , which shows the structure of the extraction device for replacing a large set of blast furnaces provided by an embodiment of the present invention.

[0041] The blast furnace replacement large set extraction device provided by the present invention comprises:

[0042] Car body moving mechanism 6, support base 5, support beam 3, length adjustment mechanism 7, handle 9, hook head 1, fixed rod 8, screw press 4, mobile hook head support mechanism 2; wherein,

[0043] The number of the handle 9, the hook head 1 and the fixed rod 8 is two;

[0044] The top surface of the v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com