A kind of method that granular activated carbon is used for decolorization and impurity removal

A granular activated carbon, decolorization and impurity removal technology, applied in separation methods, chemical instruments and methods, climate sustainability, etc., can solve the problems of poor operating environment, high cost, environmental pollution, etc., and achieve long service life, easy operation, The effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

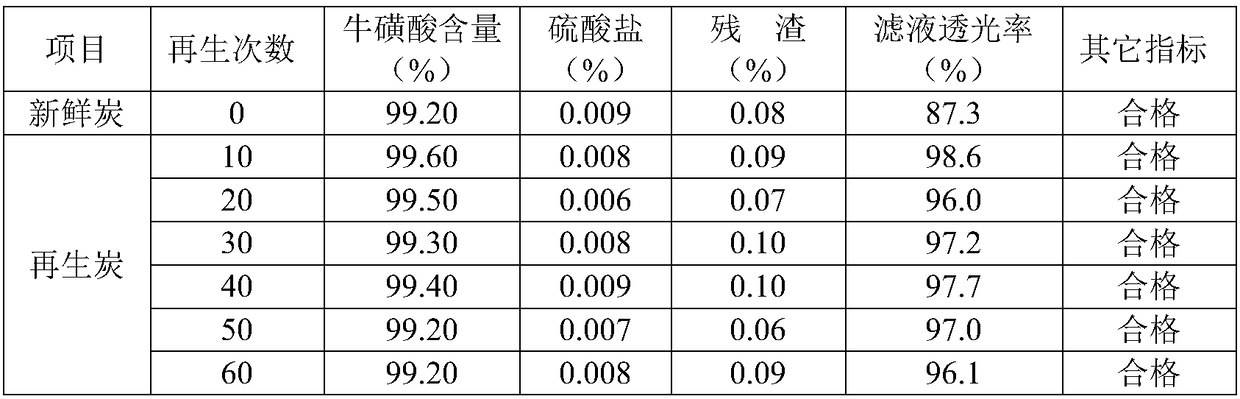

Embodiment 1

[0029] A kind of granular active carbon is used for the method for decolouring and impurity removal, and described method is applied to the decolorization and impurity removal process of taurine, comprises the following steps:

[0030] 1) coarse filtration pretreatment: dissolving the crude taurine in hot water, performing coarse filtration, filtering out the filter residue to obtain a hot solution of the crude taurine;

[0031] 2) Decolorization by granular activated carbon: pump the hot solution of crude taurine into a carbon tower filled with granular activated carbon, and decolorize and remove impurities in the process of flowing from top to bottom in the carbon tower.

[0032] The dissolving temperature of the crude taurine in the step 1) is 70-95°C.

[0033] The step 1) coarse filtration adopts sand filtration.

[0034] The step 2) granular activated carbon is produced from fruit shells or coconut shells, with a particle size of 15-80 mesh.

[0035] The light transmitt...

Embodiment 2

[0042] A kind of granular active carbon is used for the method for decolouring and impurity removal, and described method is applied to the decolorization and impurity removal process of taurine, comprises the following steps:

[0043] 1) coarse filtration pretreatment: dissolving the crude taurine in hot water, performing coarse filtration, filtering out the filter residue to obtain a hot solution of the crude taurine;

[0044] 2) Decolorization by granular activated carbon: pump the hot solution of crude taurine into a carbon tower filled with granular activated carbon, and decolorize and remove impurities in the process of flowing from top to bottom in the carbon tower.

[0045] The dissolution temperature of the step 1) crude taurine is 85°C.

[0046] The step 1) coarse filtration adopts titanium rod filtration.

[0047] The step 2) granular activated carbon is produced from fruit shells or coconut shells, with a particle size of 70 mesh.

[0048] The light transmittance o...

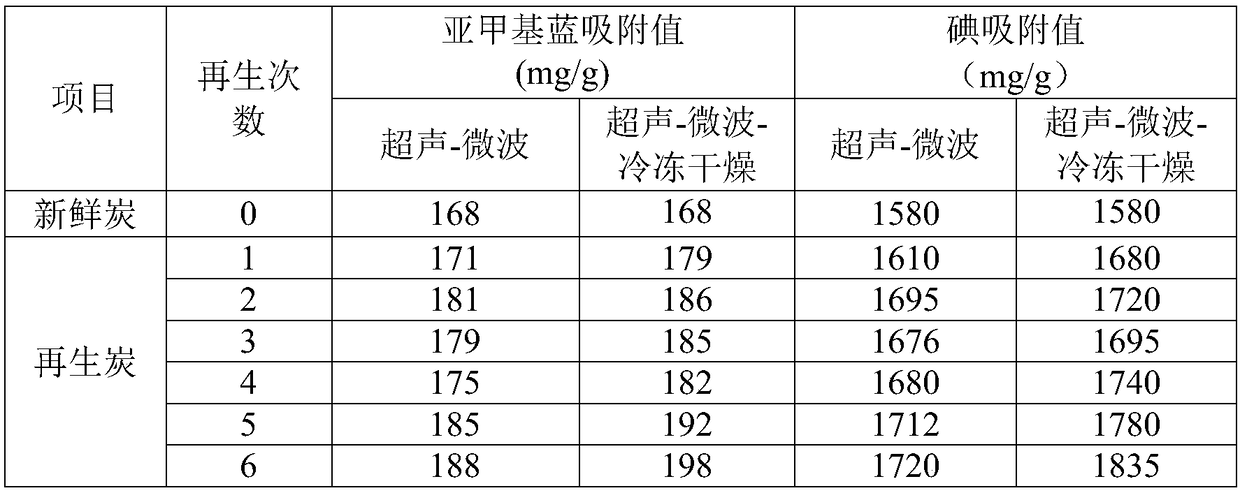

Embodiment 3

[0055] A kind of granular active carbon is used for the method for decolouring and impurity removal, and described method is applied to the decolorization and impurity removal process of taurine, comprises the following steps:

[0056] 1. Decolorization and impurity removal

[0057] Dissolve the crude taurine produced in the workshop in deionized water to make a solution with a concentration of 33-38g / 100mL, first use a polyester sponge for coarse filtration, remove flocs and a small amount of water-insoluble impurities, and then enter the transfer Then pump it into the carbon tower filled with granular activated carbon, and decolorize and remove impurities during the process of flowing from top to bottom in the carbon tower. When the light transmittance of the effluent liquid is less than 95%, the adsorption is close to saturation. Stop feeding and switch to the standby carbon tower for decolorization and impurity removal. (The temperature of dissolution, filtration and deco...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com