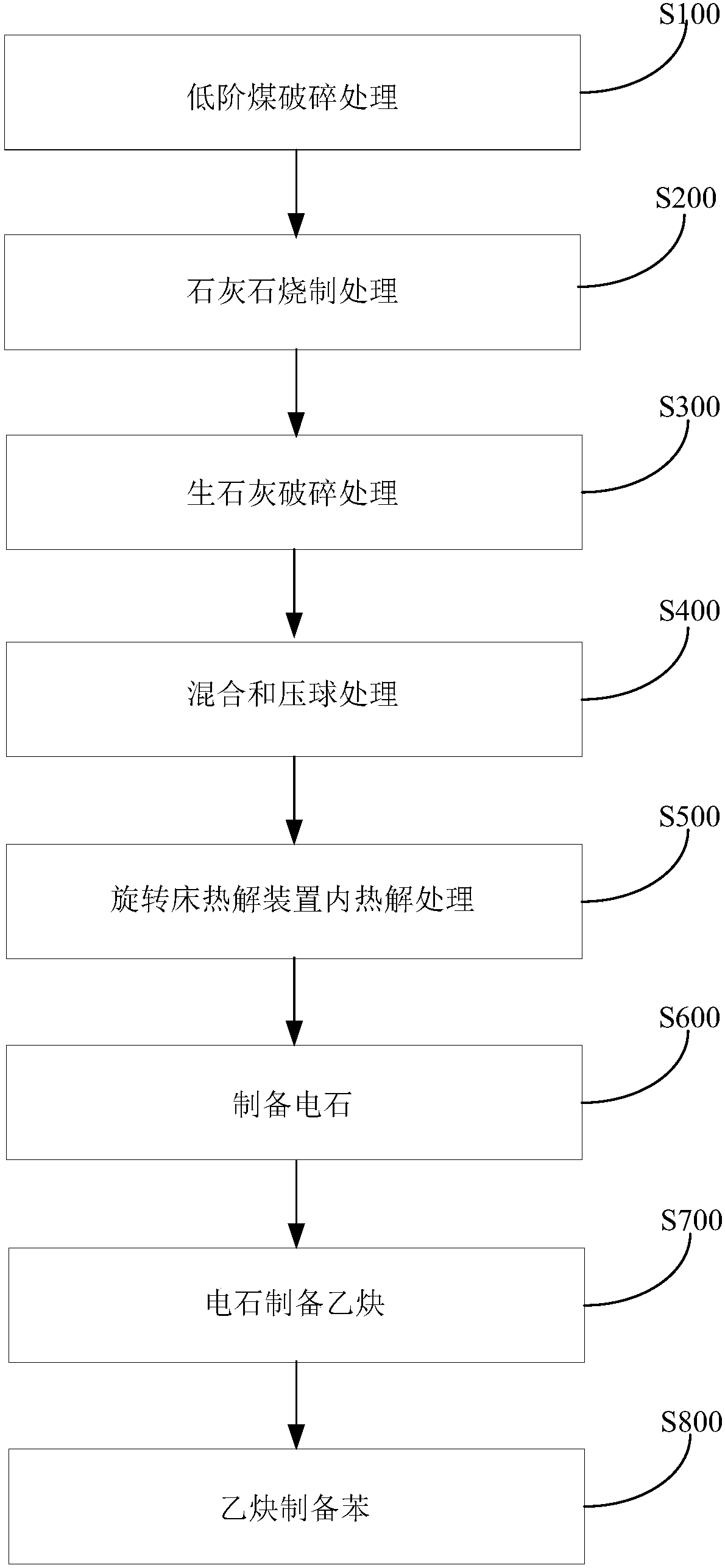

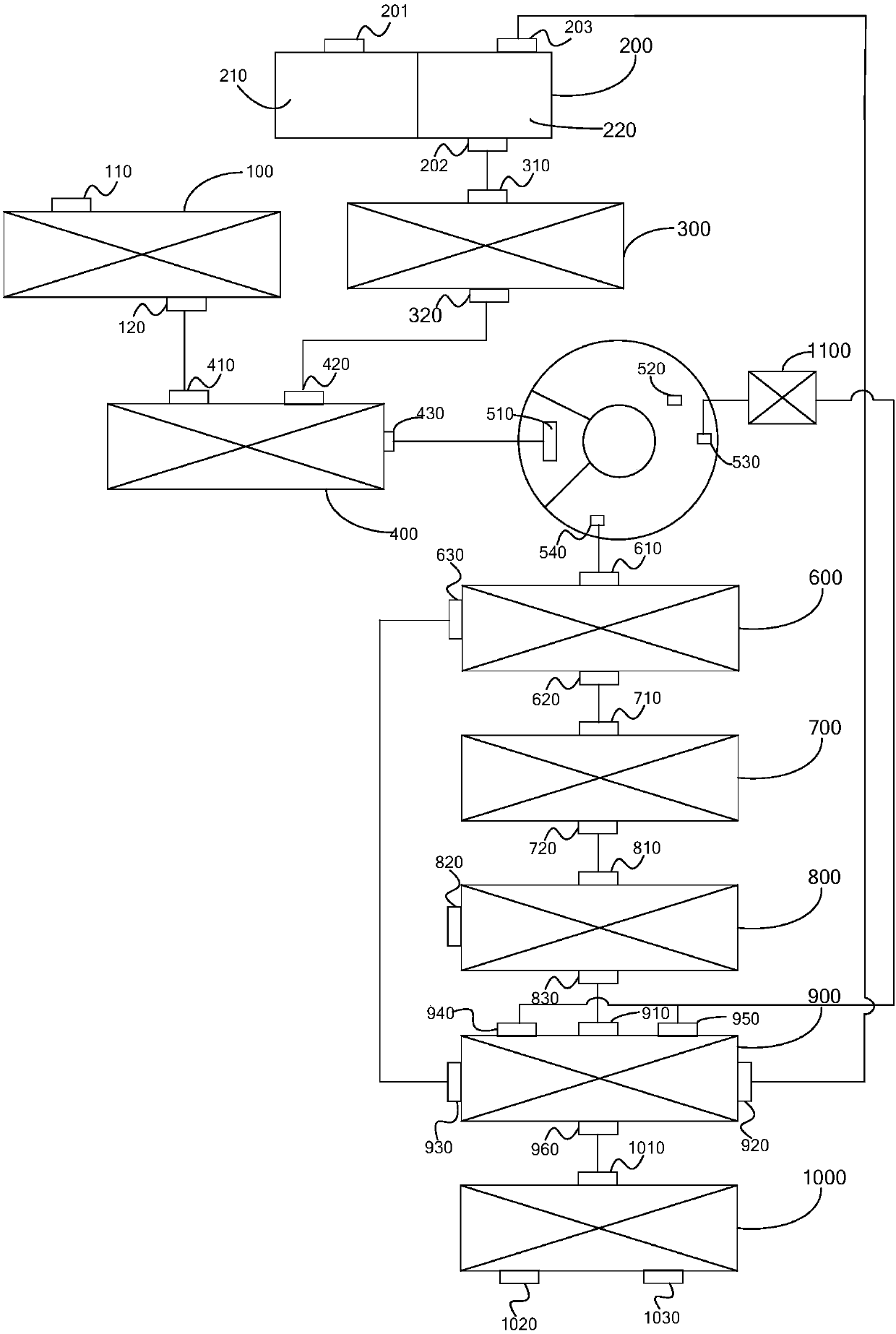

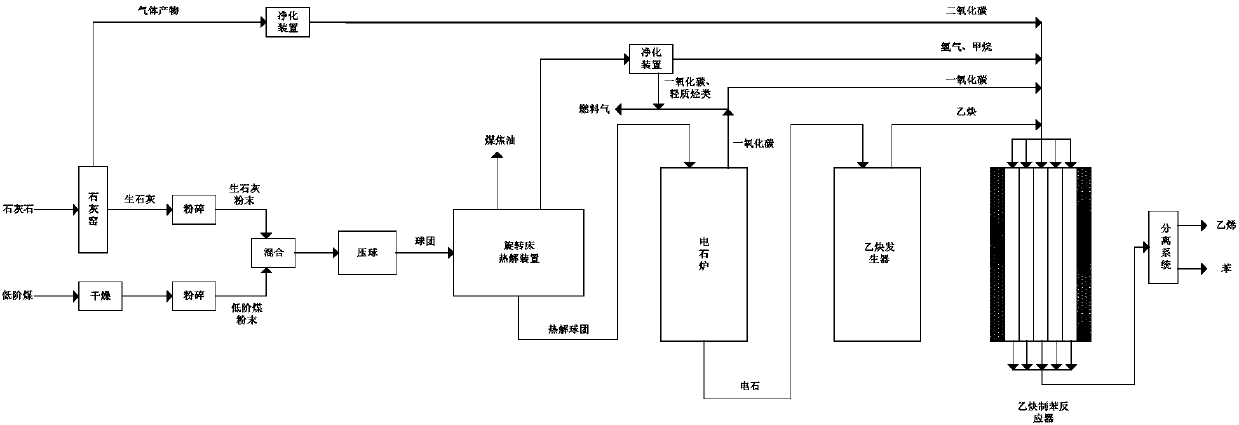

Method and system for preparing benzene with low-rank coal

A low-rank coal, imported technology, applied in the field of metallurgy, can solve the problems of waste of coal resources, low efficiency of direct combustion or gasification, and inability to fully utilize the value of resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0141] The lime and medium-low rank coal obtained from the lime kiln are crushed to less than 20 μm, the lime and medium-low rank coal are mixed at a mass ratio of 1.1:1, an appropriate amount of binder is added, and the pellets are pressed to control the diameter of the pellets to 10-40mm. The pellets are sent to a rotating bed pyrolysis device, the pyrolysis temperature is 800°C, and the pyrolysis time is 1h. The obtained pyrolysis pellets are thermally loaded into the calcium carbide furnace to produce calcium carbide. The calcium carbide produced is cooled and pulverized, and the particle size of the calcium carbide is controlled between 50 and 80 mm, and then enters the acetylene generator to react to obtain acetylene. Through this system, 1000kg of medium and low-rank coal and 2050kg of limestone can obtain about 370kg of acetylene, about 95kg of hydrogen, about 204kg of methane, 800kg of carbon dioxide and 420kg of carbon monoxide. The obtained acetylene, hydrogen, met...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com