Charcoal for tobacco field soil improvement and preparation method of charcoal

A soil improvement and biochar technology, applied in the direction of carbon preparation/purification, application, fertilizer mixture, etc., can solve the problem of improving the physical and chemical properties of farmland soil and promoting crop production and quality, the content of biochar products and the physical and chemical properties Unstable properties, no increase in production and efficiency of flue-cured tobacco, etc., to achieve the effect of increasing the maximum water holding capacity, improving physical and chemical properties, and increasing the carbon-nitrogen ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

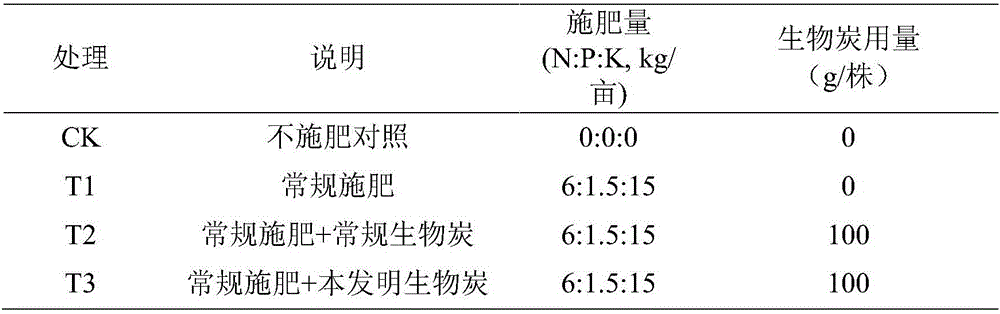

Method used

Image

Examples

Embodiment 1

[0023] 36% of sorghum, 22% of rice, 18% of glutinous rice, 16% of wheat, and 8% of corn are used for mixed fermentation to make wine; the obtained distiller's grains are calcined in a calciner to obtain a calcined product. The temperature in the calciner is 700° C., and the cracking time is 3min; the calcined product is washed with water to obtain a biochar product, the organic carbon of the biochar is ≥30%, the silicon dioxide is ≥25%, the water content is ≤45%, the ash content is ≤20%, and the particle size (1.00㎜~4.75mm )≥80%, porosity≥40%, pH≤7.0.

Embodiment 2

[0025] 55% sorghum, 20% rice, 15% wheat, and 10% corn are used for mixed fermentation to make wine; the obtained distiller's grains are calcined in a calciner to obtain a calcined product, the temperature in the calciner is 600°C, and the cracking time is 3 minutes; the calcined product The biochar product is obtained by washing with water, and the organic carbon of the biochar is ≥30%, the silicon dioxide is ≥25%, the water content is ≤45%, the ash content is ≤20%, and the particle size (1.00㎜~4.75mm) is ≥80%. , porosity ≥ 40%, pH ≤ 7.0.

Embodiment 3

[0027] 52% of sorghum, 28% of wheat, and 20% of corn are used for mixed fermentation to make wine; the obtained distiller's grains are calcined in a calciner to obtain a calcined product, the temperature in the calciner is 650°C, and the cracking time is 2 minutes; the calcined product is washed with water To obtain biochar products, the organic carbon of the biochar is ≥ 30%, the silica ≥ 25%, the water content is ≤ 45%, the ash content is ≤ 20%, the particle size (1.00㎜~4.75mm) is ≥ 80%, and the porosity is ≥ 40%, pH≤7.0.

PUM

| Property | Measurement | Unit |

|---|---|---|

| water content | aaaaa | aaaaa |

| Ash content | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com