Circulating vertical conveyer

A vertical conveyor, circulating technology, used in conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of manual loading or unloading, unable to maintain stability, and low degree of automation. The effect of intelligent stop and feeding, compact structure and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

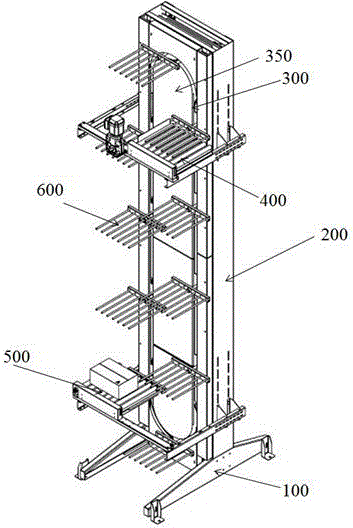

[0033] Embodiment: a kind of circular vertical conveyor.

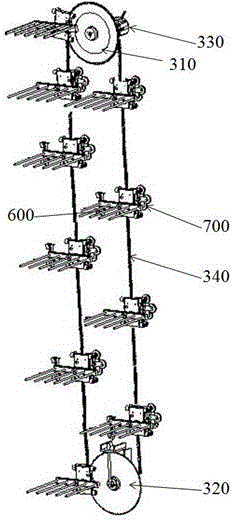

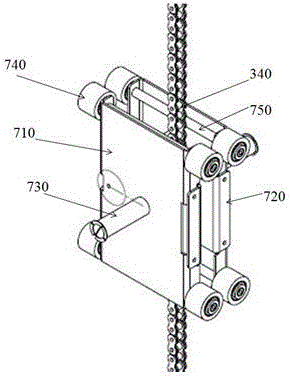

[0034] refer to Figure 1 to Figure 9 As shown, a circular vertical conveyor includes: two parallel bases 100; a frame 200 fixed on the two parallel bases 100, the frame 200 is provided with an elliptical guide rail 300; The upper end of the guide rail 300 and the drive gear 310 fixed on the frame 200, the drive motor 330 is installed at the rear of the drive gear 310; the driven gear 320 installed at the lower end of the oval guide rail 300, the drive gear 310 and the driven gear 320 are connected by a transmission chain 340; the feeding conveying device 400 arranged on the upper end of the circular or oval guide rail 300 and fixed on the frame 200; the discharging conveying device 500 fixed on the lower end of the frame 200; ten evenly spaced fixed The mobile cage 700 on the transmission chain 340, the mobile cage 700 includes a cover plate 710 and a chain fixing device 720, one end of the chain fixing device 720 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com