Portable chicken stripping and slicing machine with collection mechanism

A collection mechanism and convenient technology, applied in the field of portable chicken dicing machines, can solve the problems of not being able to ensure the smooth operation of the whole machine, the dicing effect will not be uniform, and the dicing is not very convenient, etc., so as to improve production. Efficiency and quality, stable production quality, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

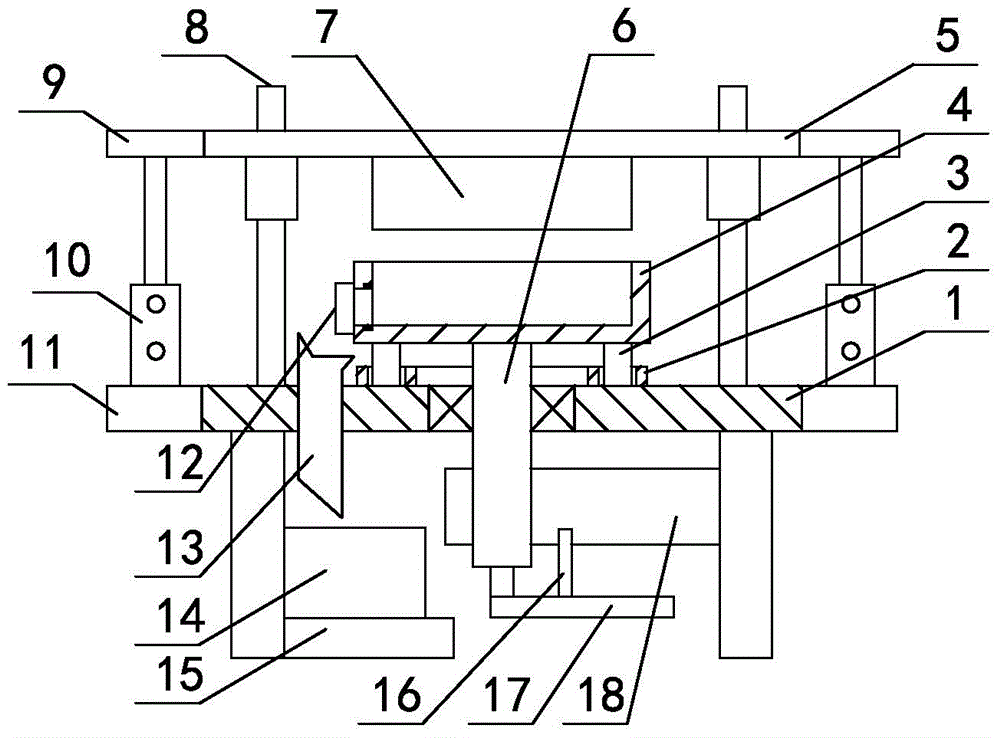

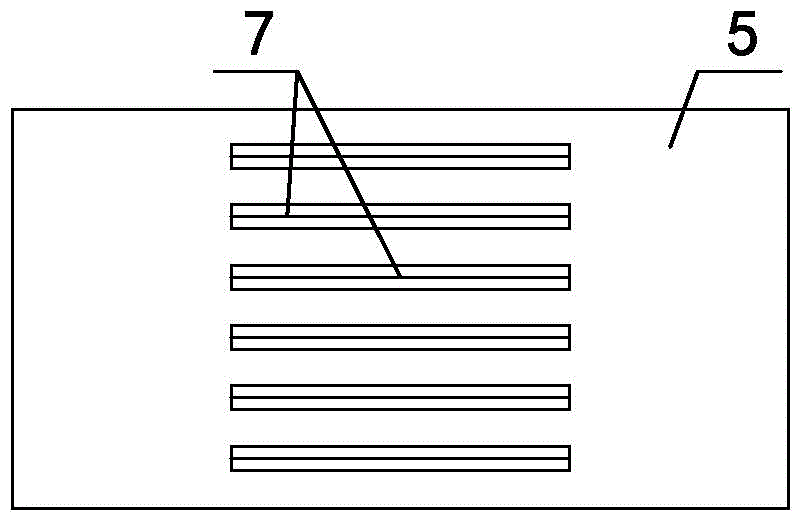

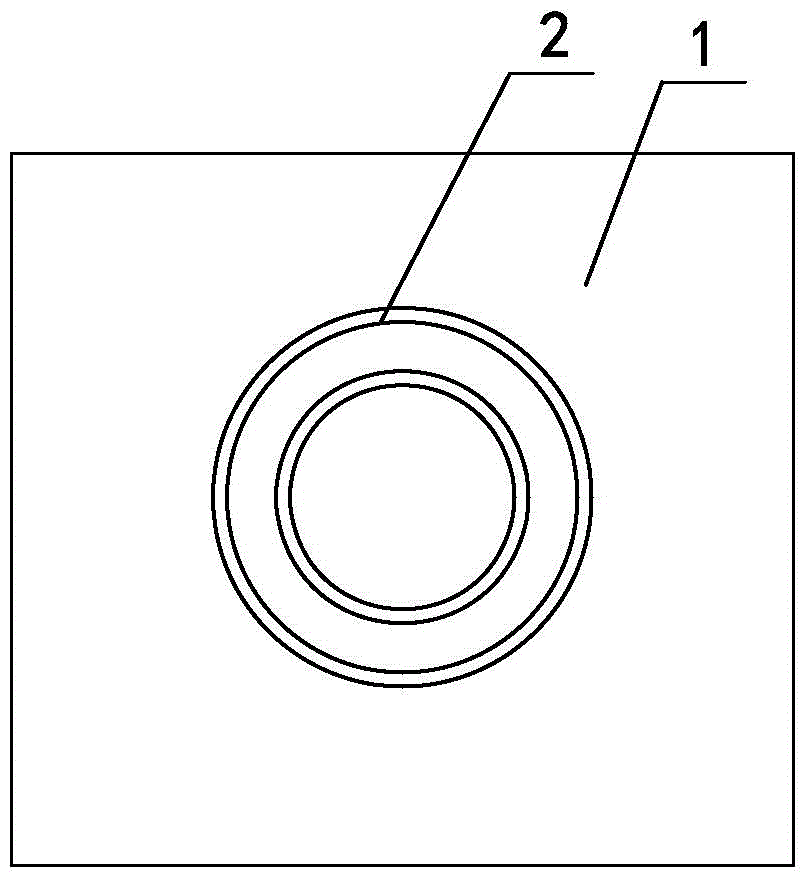

[0026] Such as figure 1 , figure 2 , image 3 As shown, the portable chicken dicing machine with a collection mechanism includes a workbench 1, and two guide rods 8 are arranged vertically and parallelly on the top of the workbench 1, on which guide rods 8 are mounted with a mounting mechanism that slides up and down. Plate 5, between the workbench 1 and the mounting plate 5, a cutting knife group and a cutting groove 4 that are mutually cut and matched are arranged, and the bottom of the cutting groove 4 is vertically provided with a rotating shaft 6, and the rotating shaft 6 is vertically installed on the working surface through a bearing. On platform 1, the cutting knife group is composed of several cutting knives 7 arranged in parallel at equal intervals. The distance between adjacent cutting knives 7 is 2mm. Door 12, corresponding discharge door 12 is vertically provided with feeding passage 13 on workbench 1, and the level below feeding passage 13 is provided with pla...

Embodiment 2

[0030] On the basis of the first embodiment, the distance between the adjacent cutting knives 7 is changed to 5mm; the groove depth of the cutting groove 4 is 80mm; the length of the cutting knives 7 is 500mm.

[0031] Others are the same as embodiment one.

Embodiment 3

[0033] Based on the first embodiment, the distance between the adjacent cutting knives 7 is changed to 5 mm; the depth of the cutting groove 4 is changed to 55 mm; the length of the cutting knives 7 is changed to 300 mm.

[0034] Others are the same as embodiment one.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com