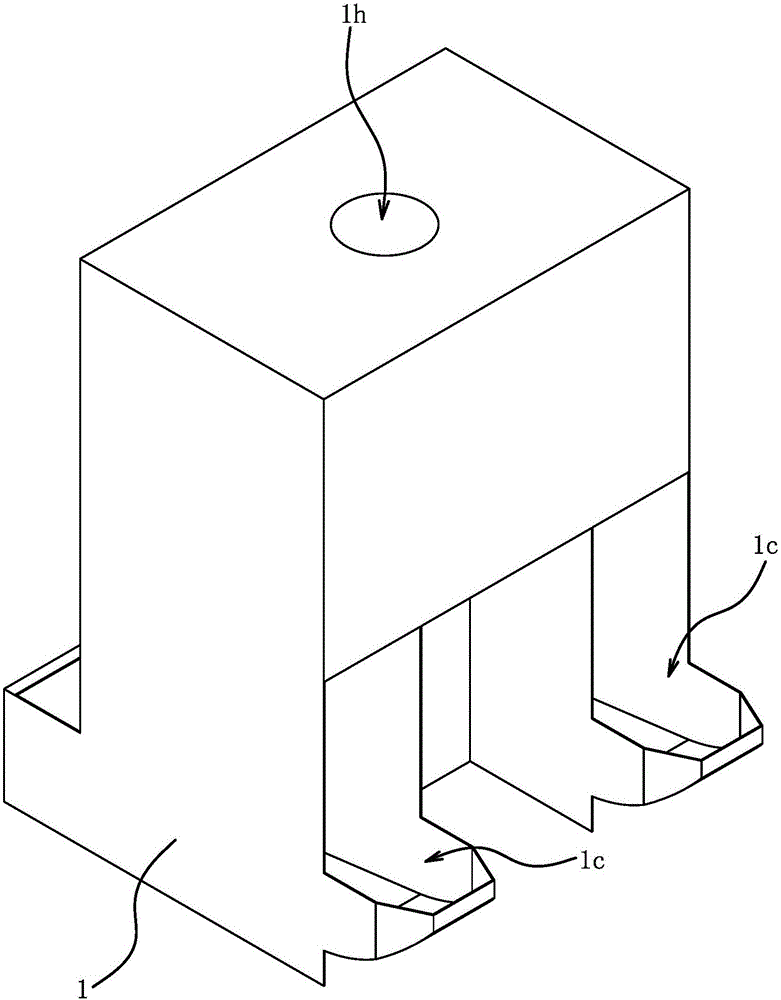

Wet polishing dust collector

A wet polishing and dust collector technology, applied in grinding/polishing equipment, surface-polished machine tools, grinding/polishing safety devices, etc., can solve problems such as explosion, plant burning, and inability to prevent dust burning, and achieve low energy consumption , the effect of reducing the occupied area, reducing the possibility of fire and explosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

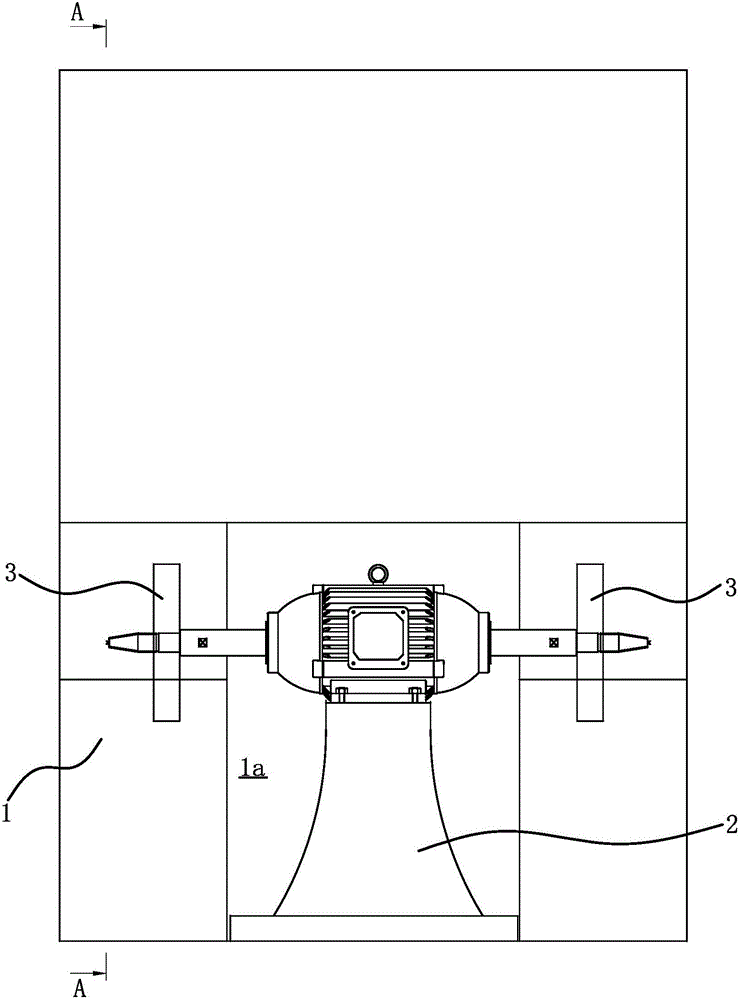

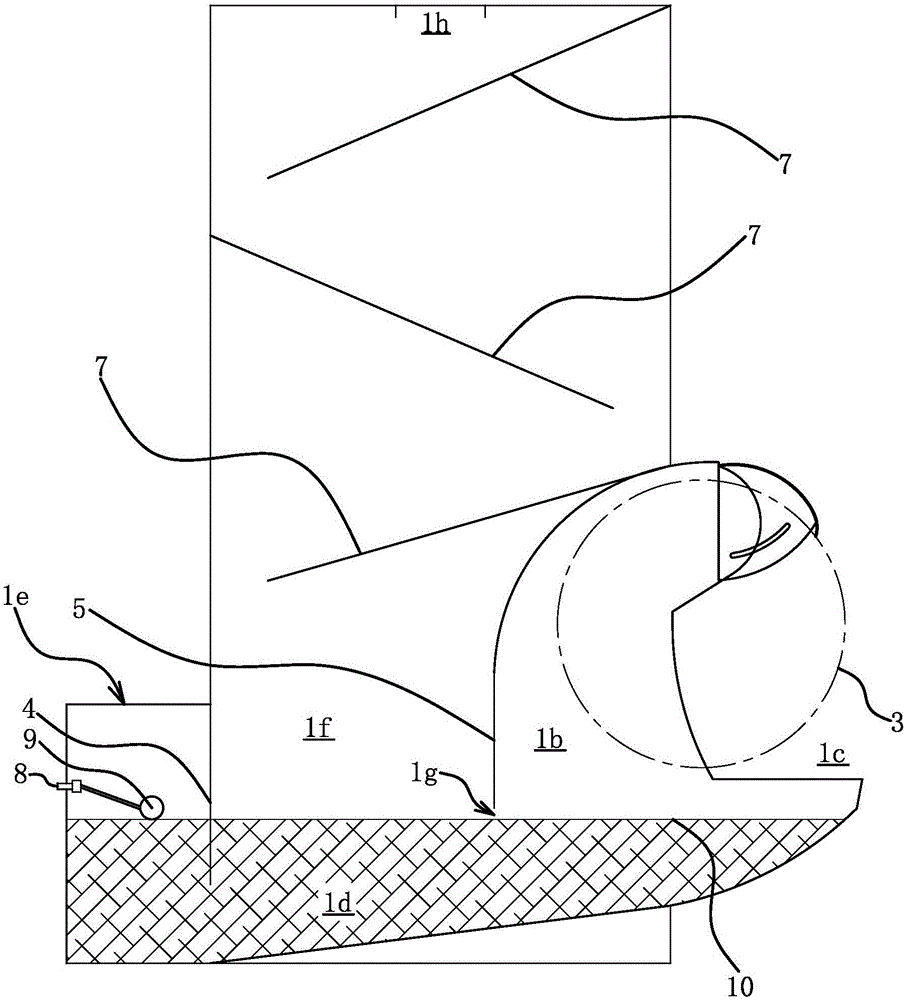

[0033] The structure and principle of this embodiment are basically the same as that of Embodiment 1, and the basic similarities will not be redundantly described, and only the differences will be described, and the differences are as follows: Figure 4 As shown, a fan 6 connected to the air outlet 1h is fixed on the top plate of the housing 1, so that the airflow of the two polishing dust collection areas 1b is generated by the above-mentioned fan 6.

Embodiment 3

[0035] The structure and principle of this embodiment are basically the same as that of Embodiment 1, and the basic similarities will not be described repeatedly, only the differences will be described. The difference is that a water storage tank 11 is fixed on the top of the housing 1 to store water. Tank 11 can store water, and water storage tank 11 is connected with water inlet pipe 8, and this water both replenishes in the water holding area 1d, also can be used for fire-fighting water, and then significantly improved the safety of polishing operation area.

Embodiment 4

[0037] The structure and principle of this embodiment are basically the same as those of Embodiment 1, and the basic similarities will not be described repeatedly, only the differences will be described. The difference is that this wet polishing dust collector only has one polishing dust collection area 1b , which is a single-station polishing dust collector; this wet polishing dust collector is suitable for use in large cloth wheel polishing machines.

[0038] The left and right sides of the rear part of the housing 1 are provided with dust removal ports 1e. A maintenance door 1i is provided on the rear side wall of the air outlet area 1f, which is convenient for people to clean the dust collected on the inclined plate 7. The three sides of the swash plate 7 are sealed and connected to the housing, and the other side has a downward-turned edge with a width of 5-15mm. The edge can increase the possibility of airflow colliding with the swash plate, thereby increasing water vapo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com