Method for casting annular thin-wall castings by means of feeding stack box of gating system

A pouring system and stacked box casting technology, which is applied in casting molding equipment, molds, mold components, etc., can solve the problems of difficult material hardness at the cold iron, large differences in pouring temperature, wrong machining allowance, etc., to achieve the appearance of The effect of good quality, high yield, improving production efficiency and product qualification rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

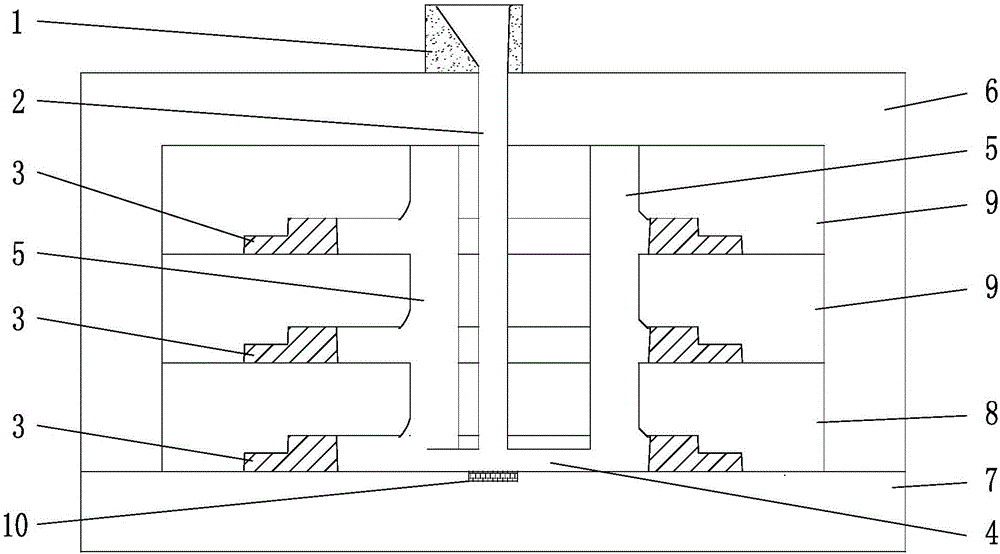

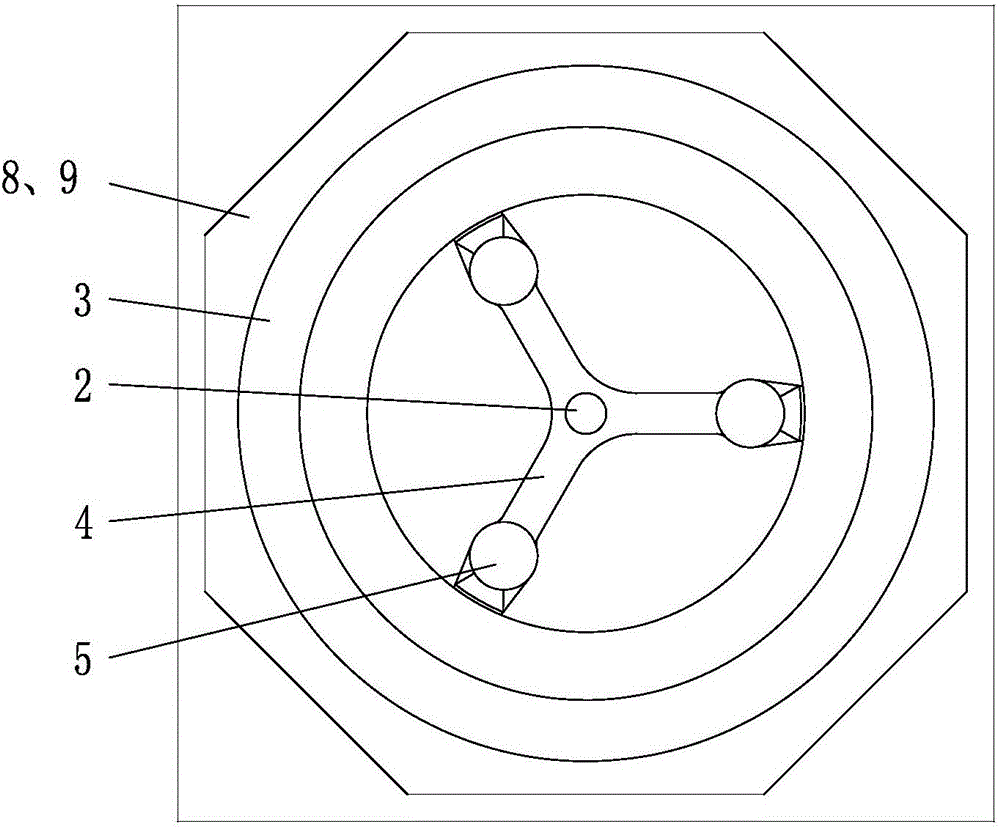

[0033] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0034] A casting process method for filling a shrink stack bearing cap with a gating system, specifically includes the following steps:

[0035] In the operation process of the present invention, taking casting bearing caps as an example, specifically three bearing caps in a box with a diameter of 1000mm are used for casting, such as figure 1 As shown, the feeding runners 5 are evenly distributed in three equal parts along the circumferential direction of the casting. Generally, three feeding runners are arranged in equal parts within a diameter of 1500mm. However, the diameter of the bearing cap widely used in the market is within 1500mm, so three Feeding runners can meet the purpose of effective feeding, and for special-diameter annular thin-walled parts, the larger the diameter of the casting, the more feeding runners need to be set.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com