New disinfection material for wet wipe and preparation method of new disinfection material

A technology of new materials and wet wipes, applied in botany equipment and methods, disinfectants, plant raw materials, etc., can solve the problems of side effects, incomplete disinfection, etc., and achieve high killing efficiency, simple preparation method, and convenient use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

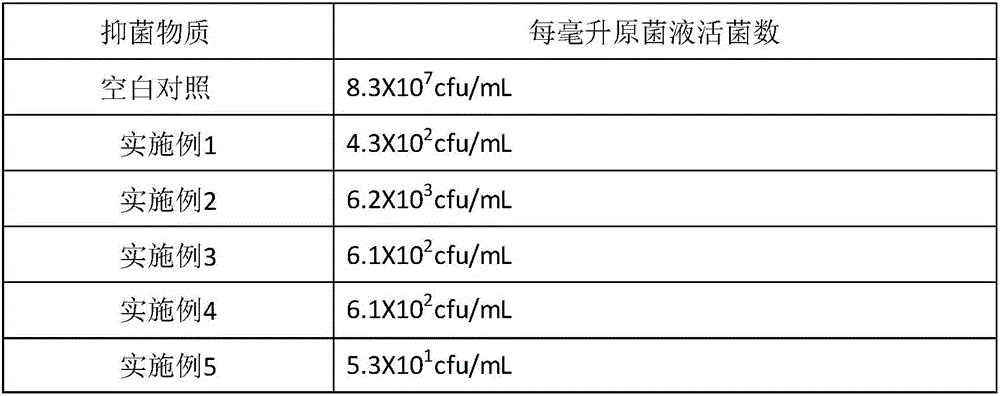

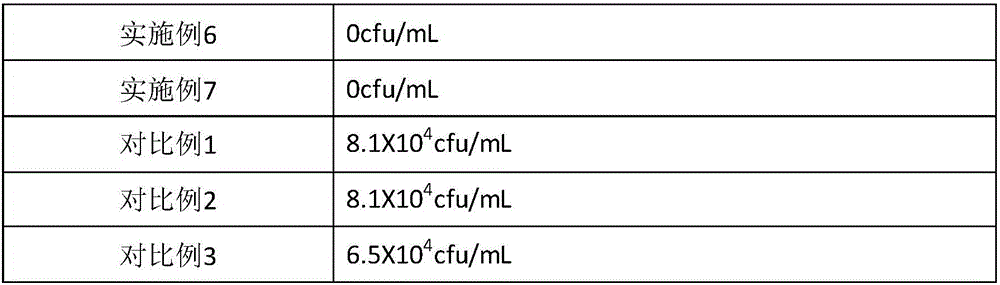

Examples

Embodiment 1

[0015] A new material for disinfection wet wipes, which is made by absorbing disinfection materials on fiber towels, and the disinfection materials are made of the following raw materials in parts by weight: 5 parts of tea polyphenols, 25 parts of lobelia extract, and inula inula extract 15 parts, 15 parts of Cinnamomum vulgaris extract, 4 parts of turpentine oil, 4 parts of limonene, 15 parts of hook hair grass, 80 parts of 70% ethanol aqueous solution.

[0016] The extraction method of the lobelia extract is as follows: crush the lobelia into powder, dry at 60° C., add 5 times the weight of ultrapure water, extract at 121° C. for 20 minutes, filter, and evaporate the filtrate to dryness.

[0017] The extraction method of the Inula inula extract is as follows: crush the Inula inula into powder, dry at 70°C, add 5 times the weight of ultrapure water, extract at 121°C for 20 minutes, filter, decolorize with activated carbon, and evaporate the filtrate to dryness.

[0018] The e...

Embodiment 2

[0023] A new material for disinfection wet wipes, which is made by absorbing disinfection materials on fiber towels. The disinfection materials are made of the following raw materials in parts by weight: 3 parts of tea polyphenols, 20 parts of lobelia extract, and inula extract 10 parts, 10 parts of Cinnamomum vulgaris extract, 2 parts of turpentine oil, 3 parts of limonene, 10 parts of hook hair grass, 60 parts of 70% ethanol aqueous solution.

[0024] The extraction method of the lobelia extract is as follows: crush the lobelia into powder, dry at 50° C., add 3 times the weight of ultrapure water, extract at 121° C. for 10 minutes, filter, and evaporate the filtrate to dryness.

[0025] The extraction method of the Inula inula extract is as follows: crush the Inula inula into powder, dry at 50°C, add 3 times the weight of ultrapure water, extract at 121°C for 10 minutes, filter, decolorize with activated carbon, and evaporate the filtrate to dryness.

[0026] The extracting ...

Embodiment 3

[0031] A new material for disinfection wet wipes, which is made by absorbing disinfection materials on fiber towels. The disinfection materials are made of the following raw materials in parts by weight: 8 parts of tea polyphenols, 35 parts of lobelia extract, and inula extract 20 parts, 20 parts of Cinnamomum vulgaris extract, 2-6 parts of turpentine oil, 3-5 parts of limonene, 10-20 parts of hook hair grass, 60-100 parts of 70% ethanol aqueous solution. .

[0032] The extraction method of the lobelia extract is as follows: crush the lobelia into powder, dry at 80° C., add 8 times the weight of ultrapure water, extract at 121° C. for 30 minutes, filter, and evaporate the filtrate to dryness.

[0033] The extraction method of the Inula inula extract is as follows: crush the Inula inula into powder, dry at 80°C, add 8 times the weight of ultrapure water, extract at 121°C for 30 minutes, filter, decolorize with activated carbon, and evaporate the filtrate to dryness.

[0034] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com