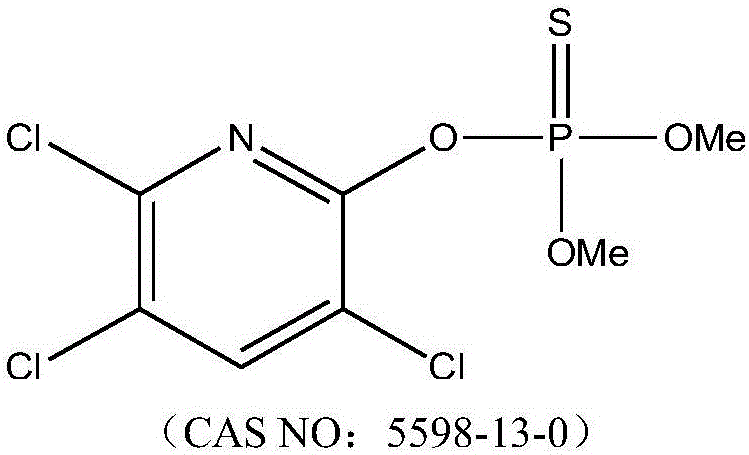

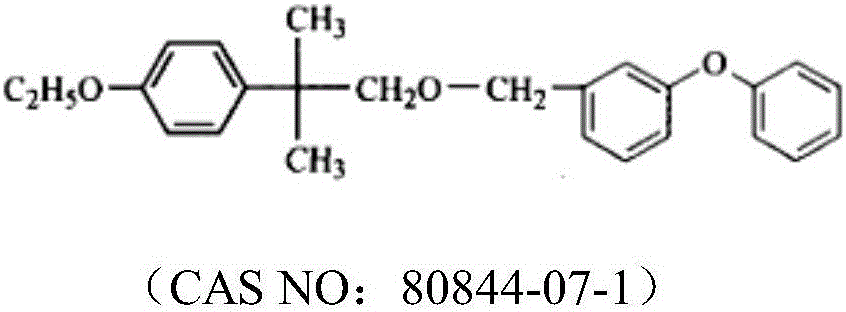

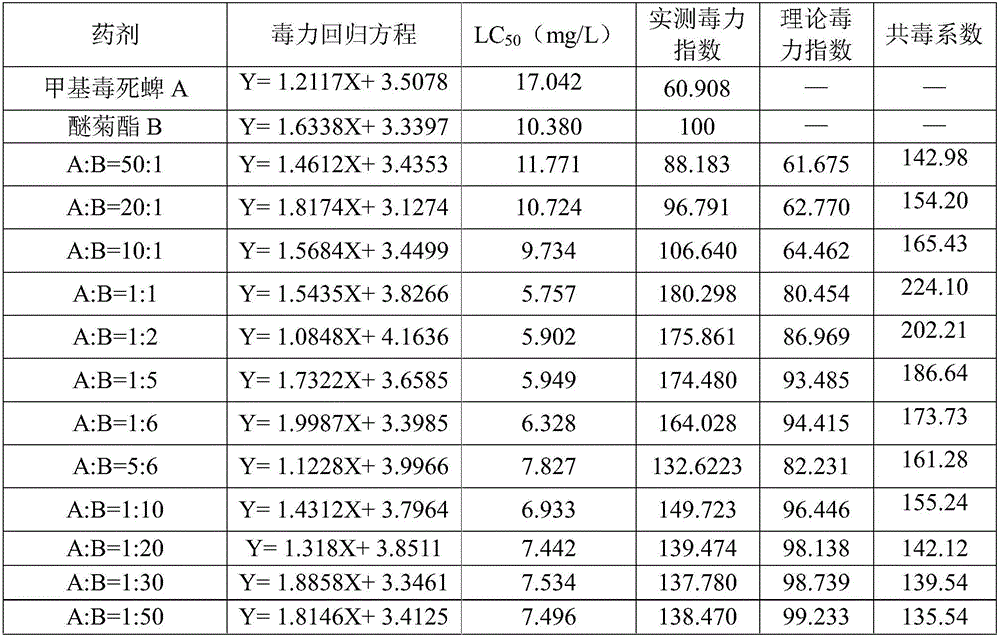

Insecticidal composition containing chlorpyrifos-methyl and etofenprox as well as preparation and application thereof

An insecticidal composition, chlorpyrifos-methyl technology, applied in the direction of insecticide, application, biocide, etc., can solve the problems that no one has reported, plant pest synergies, etc., to reduce the frequency of application, expand the control spectrum, and ensure safety sex high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Embodiment 1: 14% (2%+12%) suspending agent

[0051] 2g of chlorpyrifos-methyl and 12g of etherproxil composition, 3.0g of fatty alcohol ethoxylate, 1.0g of alkylnaphthalene sulfonate, 2.0g of fatty alcohol polyoxyethylene ether sulfate, 3.0g of phenolsulfonic acid condensate sodium salt g, ethylene glycol 3g, Cathone 0.2g, silicone defoamer 0.2g, distilled water added to 100g, put into a high-shear homogeneous emulsifier and shear at high speed for 30min, then transport it to a sand mill, and circulate Sanding 1-3 times to get 14% suspending agent. The suspension contains 14% active compound.

Embodiment 2

[0052] Embodiment 2: 20% (4%+16%) suspending agent

[0053] 4g chlorpyrifos methyl and 16g etofenprox composition, fatty alcohol polyoxyethylene ether 2.0g, alkyl naphthalene sulfonate 1.0g, sodium methylene dinaphthalene sulfonate 3.0g, xanthan gum 0.05g, silicic acid Aluminum magnesium 0.6g, glycerin 2.0g, salicylphenyl ester 0.4g, silicone defoamer 0.1g, deionized water to make up to 100g, put into high-shear homogeneous emulsifier and shear at high speed for 20 minutes, and then Transport it to a sand mill, and circulate the sand for 1-3 times to get the suspending agent. The suspension contains 20% active compound.

Embodiment 3

[0054] Embodiment 3: 30% (10%+20%) suspending agent

[0055] Mix 10g of chlorpyrifos-methyl and 20g of etofenproxil composition, 2.0g of alkyl naphthalene sulfonate, 2.0g of fatty alcohol polyoxyethylene ether sulfate, 1.0g of sodium methylnaphthalene sulfonate formaldehyde condensate, octenyl succinic acid Starch sodium 2.0g, glycerol 2.0g, butyl p-hydroxybenzoate 0.2g, polyether defoamer 0.1g, distilled water to make up to 100g, put into a high-shear homogeneous emulsifier and shear at high speed for 25 minutes, and then Pump it into a sand mill and grind it for 90 minutes, and then filter to obtain the suspending agent. The suspension contains 30% active compound.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com