Manufacturing method of super bass drum paper

A production method and subwoofer technology, applied to electrical components, sensors, etc., can solve problems such as high distortion rate, high air leakage rate, and poor bass sound quality, and achieve good sound effects, good sealing, and moderate thickness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

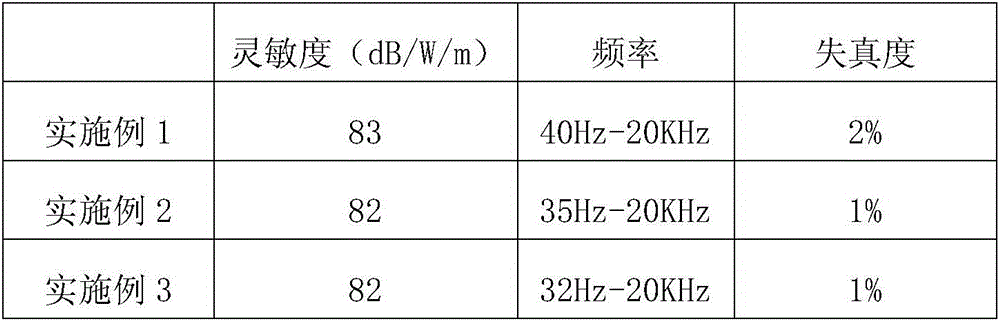

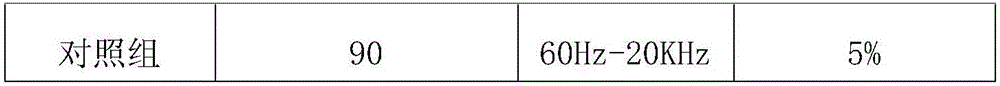

Examples

Embodiment 1

[0032] A kind of manufacture method of super bass drum paper, comprises the following steps:

[0033] (1) Beating: add water accounting for 65% of the volume of the beater into the beater tank; put the uncolored kraft softwood pulp (UKP) raw material that needs to be kneaded into the pulp tank of the beater for dissociation, and dissociate after 15 minutes. After 25 minutes of light knife, the heavy knife is used for 2 hours; after 2 hours of beating, the pulp beating degree is measured, and the knife can be lifted after reaching the required beating degree. The beating degree of natural kraft softwood pulp is 20 degrees; Softwood pulp with additives including dyes, salt, acrylic latex (ODG) water repellent and trimethyl phosphate (P615) hardener;

[0034] The order of adding and using the above-mentioned additives are as follows: first pour 7% of the weight of the slurry evenly into the slurry for 5 minutes; pour 2% of the salt into the slurry to fix the color, and leave for ...

Embodiment 2

[0046] A kind of manufacture method of super bass drum paper, comprises the following steps:

[0047] (1) Beating: add water accounting for 75% of the volume of the beater into the beater tank; put the bleached kraft softwood pulp (BKP) raw material into the pulp tank of the beater for freeing; after freeing for 25 minutes, place a light knife for 35 minutes After that, the heavy knife is lowered for 2.5 hours; the degree of pulp beating is measured after 2.5 hours of beating, and the knife can be lifted after reaching the required beating degree. The beating degree of bleached kraft softwood pulp is 20 degrees; Additives including dyes, salts, acrylic latex (ODG) water repellants and trimethyl phosphate (P615) hardeners;

[0048] Among them, the order of adding additives and the method of use are as follows: first evenly pour 10% of the dyestuff by the weight of the slurry into the slurry, and let it free for 8 minutes. The dyestuff in this embodiment adopts direct sunfast bl...

Embodiment 3

[0060] A kind of manufacture method of super bass drum paper, comprises the following steps:

[0061] (1) beating: add water accounting for 75% of the volume of the beater in the beater pool; put the cotton pulp raw material into the pulp pool of the beater to free; after free for 20 minutes, place a light knife for 30 minutes and then a heavy knife for 2 hours; After beating for 2 hours, measure the degree of pulp beating, lift the knife after reaching the required beating degree, and add additives including dye, salt, acrylic latex (ODG) waterproofing agent and trimethyl phosphate (P615) hardener;

[0062] Among them, the order of adding and using the above additives is as follows: firstly pour 8% of the dyestuff by the weight of the slurry evenly into the slurry, and let it free for 5 minutes. Bright red (direct sunfast black G: direct bright red=10:1.5), increase the blackness of the paper cone; pour 2% of the salt into the slurry to fix the color, free for 5 minutes; add ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com