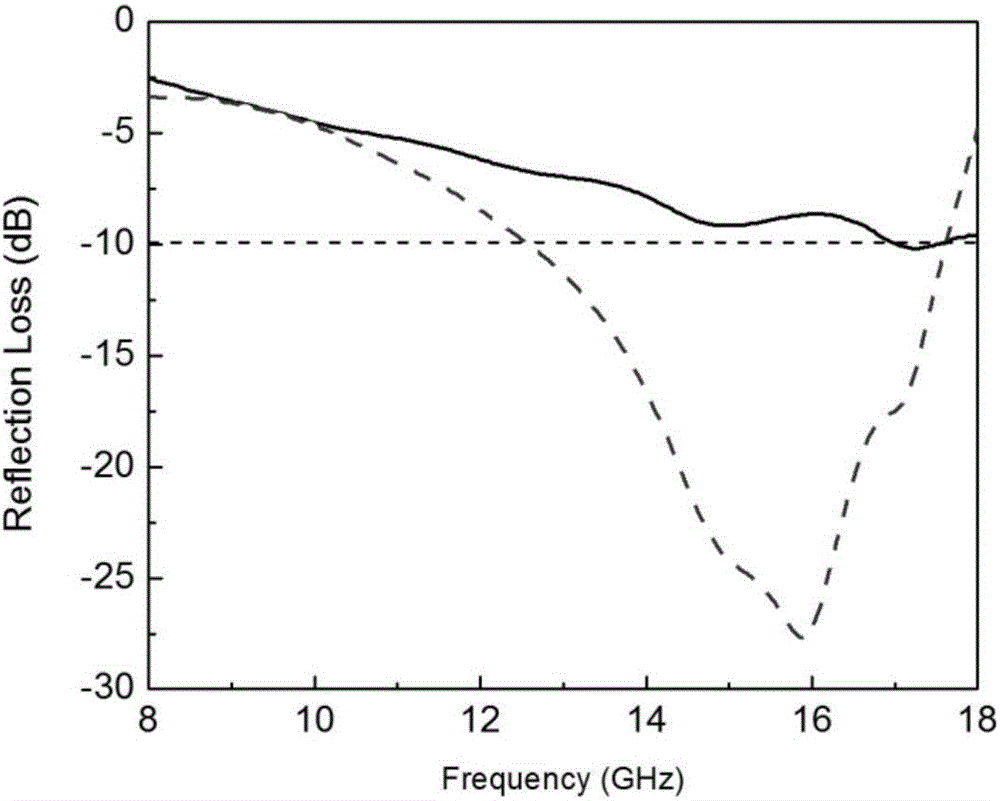

Miura - Ori origami structure electromagnetic stealthl plate of loaded graphene metamaterial unit

A unit structure and stealth board technology, applied in shielding materials, electrical components, magnetic field/electric field shielding, etc., can solve the problems of single frequency modulation dimension space, frequency modulation bandwidth range and mechanism limitations, and achieve the effect of wide absorption efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Step 1: Dissolve graphene oxide in water to prepare a graphene oxide aqueous solution with a concentration of 7.5 mg / ml, add hydroquinone to the graphene oxide aqueous solution, and stir evenly; the mass ratio of hydroquinone to graphene oxide is 5 ;

[0031] Step 2: Immerse the substrate in the above mixed solution, and seal it; heat preservation treatment at 100°C for 10 hours, so that the absorbing medium is attached to the substrate; the substrate is polymer fabric or polymer foam; the thickness of the substrate is 2mm ;

[0032] Step 3: Take the substrate with the absorbing medium out of the mixture, soak it in water and wash it, spread it into a straight plate, freeze it at -40°C for 10 hours, and dry it at room temperature for 48 hours to obtain a graphene woven fabric ;

[0033] Step 4: Mix epoxy resin and epoxy resin curing agent in a mass ratio of 1:3 to form an epoxy resin precursor solution; dip the graphene fabric obtained in step 3 into the epoxy resin p...

Embodiment 2

[0039] Step 1: dissolving graphene oxide in water to prepare a graphene oxide aqueous solution with a concentration of 4 mg / ml, adding hydroquinone to the graphene oxide aqueous solution, and stirring evenly; the mass ratio of hydroquinone to graphene oxide is 2;

[0040] Step 2: Immerse the substrate in the above mixture, and seal it; heat preservation treatment at 120°C for 8 hours to attach the absorbing medium to the substrate; the substrate is polymer fabric or polymer foam; the thickness of the substrate is 2mm ;

[0041] Step 3: Take the substrate with the absorbing medium out of the mixture, soak it in water and wash it, spread it into a straight plate, freeze it at -40°C for 12 hours, and then dry it at room temperature for 36 hours to obtain a graphene woven fabric ;

[0042] Step 4: Mix epoxy resin and epoxy resin curing agent in a mass ratio of 1:3 to form an epoxy resin precursor solution; dip the graphene fabric obtained in step 3 into the epoxy resin precursor ...

Embodiment 3

[0048] Step 1: Dissolving graphene oxide in water to prepare a graphene oxide aqueous solution with a concentration of 2 mg / ml, adding hydroquinone to the graphene oxide aqueous solution, and stirring evenly; the mass ratio of hydroquinone to graphene oxide is 1;

[0049] Step 2: Immerse the substrate in the above mixture, and seal it; heat preservation treatment at 100°C for 8 hours, so that the absorbing medium is attached to the substrate; the substrate is polymer fabric or polymer foam; the thickness of the substrate is 2mm ;

[0050] Step 3: Take out the substrate attached with the absorbing medium from the mixture, soak it in water and wash it, spread it into a straight plate, freeze it at -40°C for 10 hours, and then dry it at room temperature for 30 hours to obtain a graphene woven fabric ;

[0051] Step 4: Mix epoxy resin and epoxy resin curing agent in a mass ratio of 1:3 to form an epoxy resin precursor solution; dip the graphene fabric obtained in step 3 into the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com