Power battery system and tray thereof

A power battery and tray technology, which is applied in the direction of secondary batteries, battery temperature control, battery pack components, etc., can solve the problems of large volume and weight of the power battery system, heavy weight, low manufacturability of power battery trays, etc., and achieve residual The thermal stress is small, the docking area is regular and straight, and the effect of increasing manufacturability and overall quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the above objects, features and advantages of the present invention more comprehensible, specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

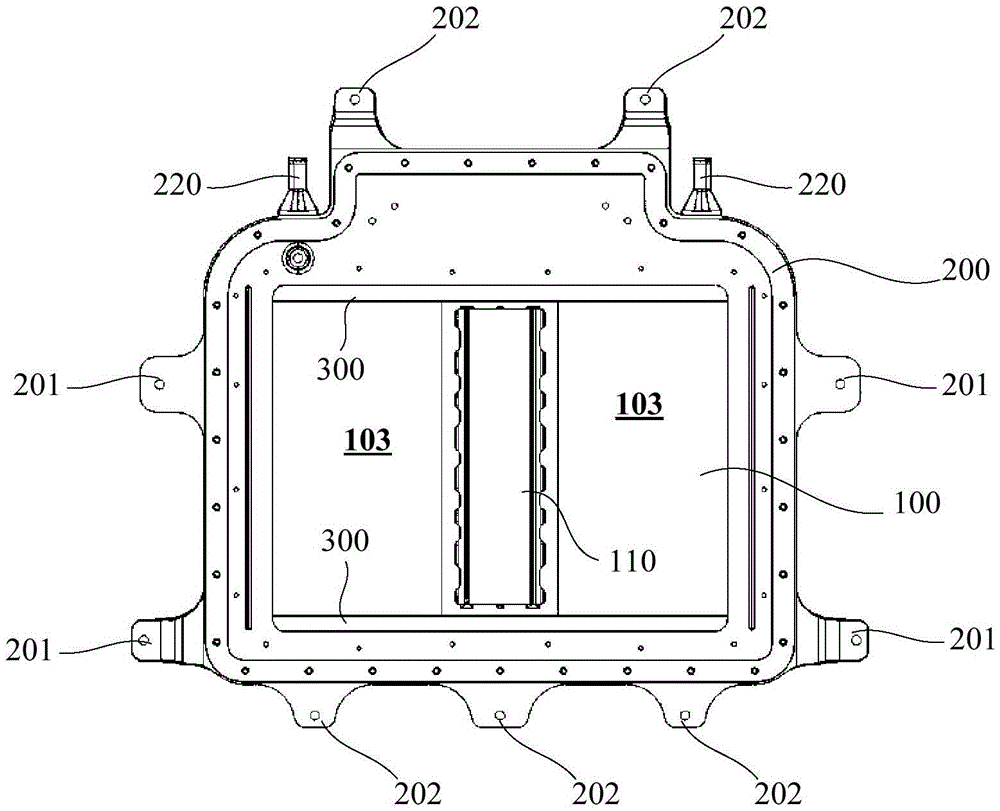

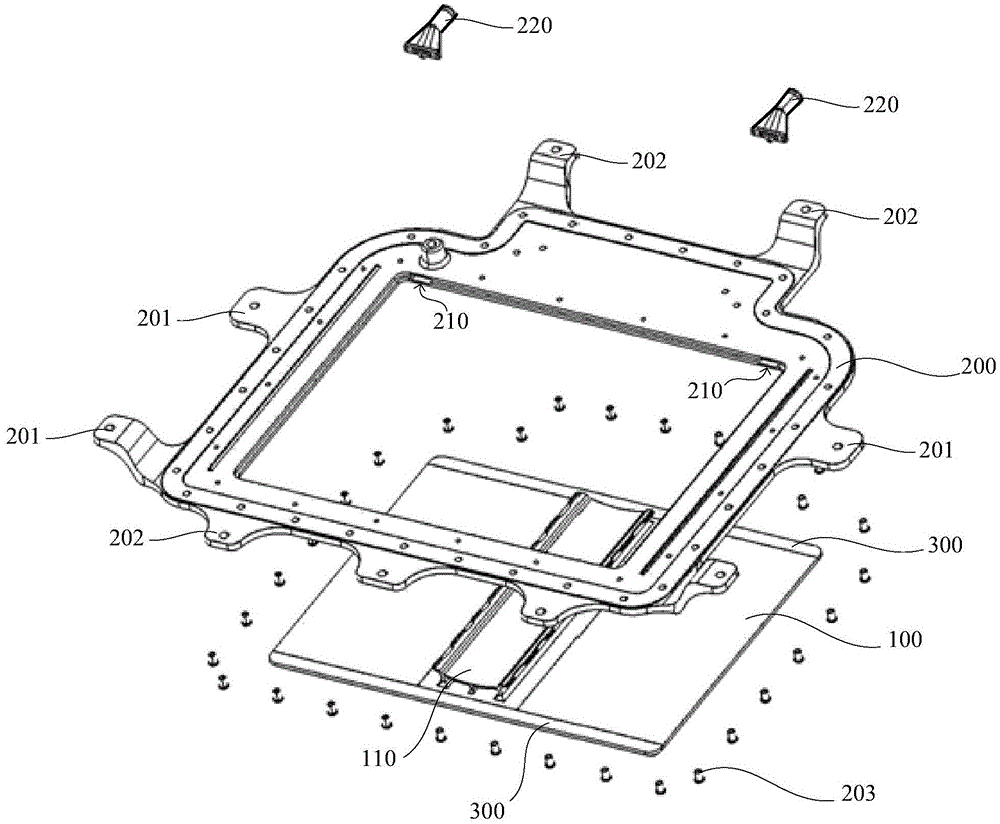

[0030] An embodiment of the present invention provides a power battery tray, referring to figure 1 , figure 2 and combine image 3 As shown, it includes a tray body 100 for installing a power battery module, and a tray frame 200 surrounding the tray body 100 and connected to the tray body 100 , and the tray frame 200 is used for connecting with a car.

[0031] The tray frame 200 is substantially rectangular, and has a substantially rectangular through hole in the middle for receiving the tray body 100 . Corresponding to the tray frame 200 , the shape of the tray main body 100 is also substantially rectangular.

[0032] Such as figure 1 As shown, the tray frame 200 includes two first sides 200a extending along the front and rear direct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com