Preparation method of asymmetric supercapacitor

A supercapacitor, asymmetric technology, applied in the field of preparation of asymmetric supercapacitors, can solve problems such as low energy density, and achieve the effect of improving energy density and power density, large surface area, and wide voltage range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

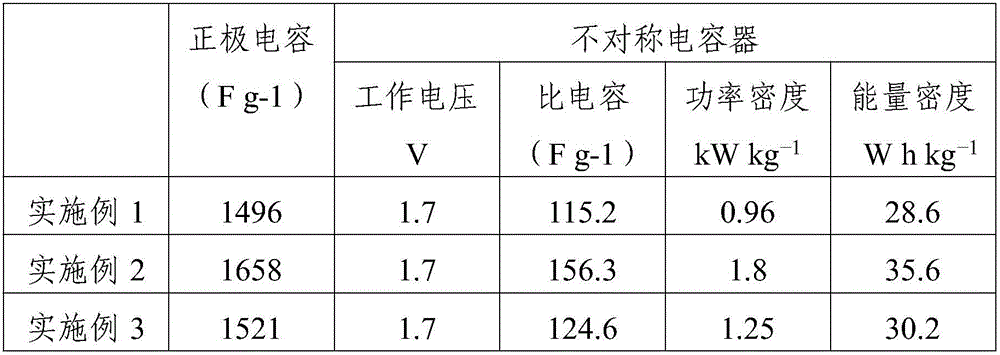

Examples

Embodiment 1

[0021] A preparation method for an asymmetric supercapacitor, comprising the following steps:

[0022] (1) Take 2mL of CuCl with a concentration of 0.1M 2 solution, take 1 mL of KOH solution with a concentration of 2M and add it to 40 mL of deionized water, stir for 30 s, add 1 mL of ascorbic acid solution with a concentration of 0.2 M, stir for 20 min, centrifuge the brick red precipitate, wash, and vacuum dry at 60 ° C for 2 h to obtain For cuprous oxide powder, add 60mg of cuprous oxide and 850mg of PVP to a mixed solution of 50mL of water and ethanol in turn, after ultrasonication for 5min, add CoCl 2 solution, stirred for 5min, and added 20mL of 1.0M Na 2 S 2 o 3 solution, after stirring for 30 minutes, the product was centrifuged, washed, and dried at 60°C for 2 hours to obtain pink cobalt hydroxide;

[0023] (2) Adding cobalt hydroxide to 50mL Na with a concentration of 0.02M 2 In the S solution, after the ultrasonic dispersion was uniform, it was transferred into ...

Embodiment 2

[0028] A preparation method for an asymmetric supercapacitor, comprising the following steps:

[0029] (1) Take 1mL of CuCl with a concentration of 0.1M 2 Solution, take 1.5mL KOH solution with a concentration of 2M and add it to 40mL deionized water, stir for 60s, add 1mL ascorbic acid solution with a concentration of 0.1M, stir for 15min, centrifuge the brick red precipitate, wash, and vacuum dry at 50°C for 5h. To obtain cuprous oxide powder, add 60mg of cuprous oxide and 800mg of PVP to the mixed solution of 50mL of water and ethanol in turn, after ultrasonication for 15min, add CoCl 2 solution, stirred for 5min, and added 20mL of 1.0M Na 2 S 2 o 3 solution, after stirring for 20 minutes, the product was centrifuged, washed, and dried at 50°C for 2 hours to obtain pink cobalt hydroxide;

[0030] (2) Add cobalt hydroxide to 50mL Na with a concentration of 0.04M 2 In the S solution, after the ultrasonic dispersion was uniform, it was transferred into a 60mL autoclave, h...

Embodiment 3

[0035] A preparation method for an asymmetric supercapacitor, comprising the following steps:

[0036] (1) Take 1 mL of CuCl with a concentration of 0.2M 2 solution, add 2 mL of KOH solution with a concentration of 1.5M into 35 mL of deionized water, stir for 90 s, add 2 mL of ascorbic acid solution with a concentration of 0.1 M, stir for 15 min, centrifuge the orange precipitate, wash, and vacuum dry at 50 °C for 2 h to obtain For cuprous oxide powder, add 50mg of cuprous oxide and 800mg of PVP to a mixed solution of 50mL of water and ethanol in turn, after ultrasonication for 20min, add CoCl 2 solution, stirred for 10min, and added 20mL of 1.0M Na 2 S 2 o3 solution, after stirring for 10 minutes, the product was centrifuged, washed, and dried at 80°C for 2 hours to obtain pink cobalt hydroxide;

[0037] (2) Adding cobalt hydroxide to 50mL Na with a concentration of 0.05M 2 In the S solution, after the ultrasonic dispersion was uniform, it was transferred into a 60mL auto...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com