Shell-and-tube lead base alloy cooling reactor

A lead-based alloy, shell-and-tube technology, applied in reactors, cooling devices, reducing greenhouse gases, etc., can solve problems such as core safety hazards, achieve high inherent safety, and eliminate the effect of core melting probability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the purpose, technical solutions and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the examples and accompanying drawings. As a limitation of the present invention.

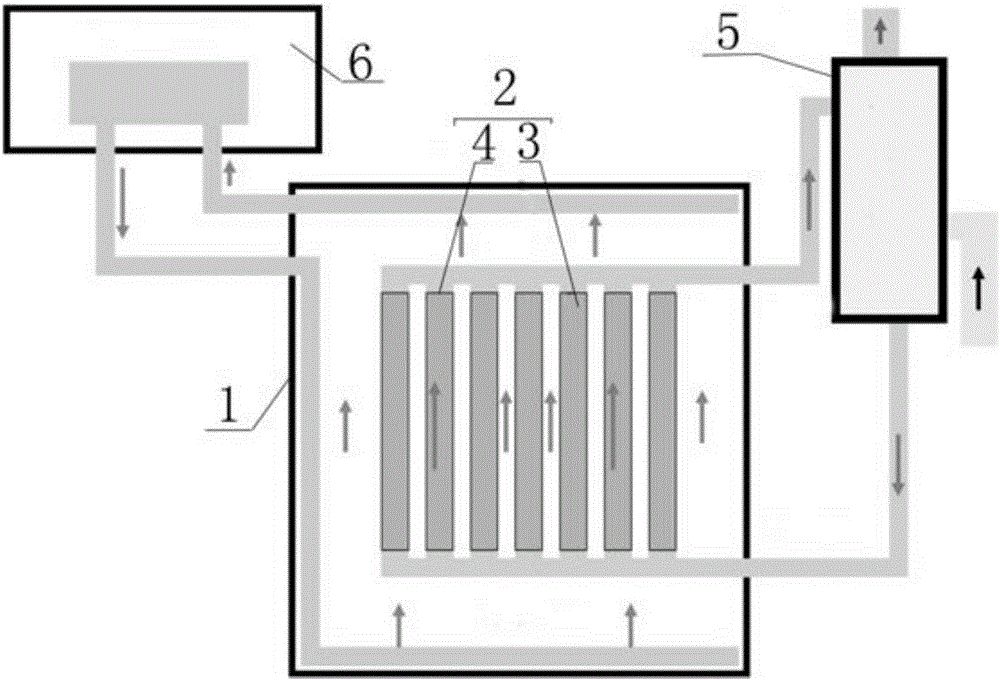

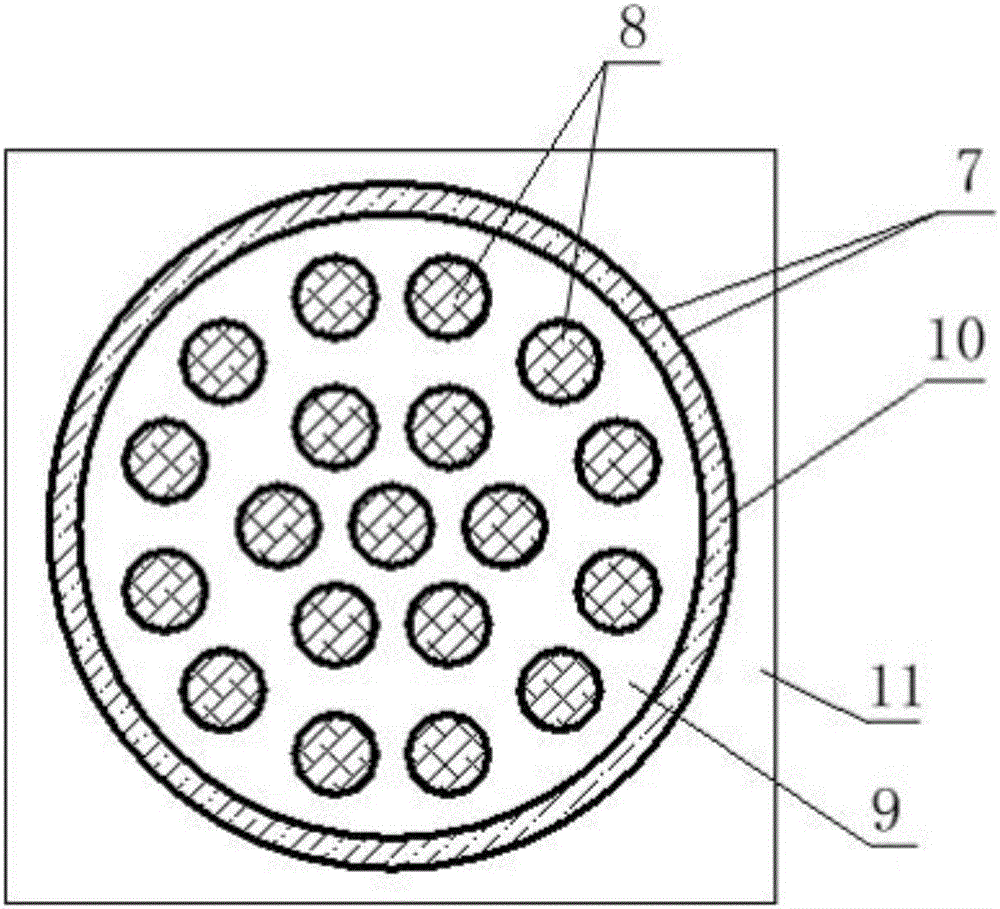

[0026] The present invention as Figure 1-2 As shown, a shell-and-tube type lead-based alloy cooling reactor includes a reactor vessel 1, a core 2, a fuel channel 3 and a pressure tube 4, and the fuel channel formed by placing the nuclear fuel assembly 8 and the lead-bismuth coolant in the pressure tube 4 3. Put several fuel passages 3 into the water pool of the reactor vessel 1 to form the core 2 . The outlets of the fuel passages 3 are connected in parallel with each other through pipes and then connected with the inlet of the steam generator 5 , and the inlets of the fuel passages 3 are connected in parallel with each other through pipes and then connected with the outlet of the steam generator 5 . The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com