High-reflective surface three-dimensional measuring device and method based on digital micromirror

A digital micromirror and three-dimensional measurement technology, which is applied in measurement devices, optical devices, instruments, etc., can solve the problems of difficult measurement of highly reflective surfaces, and achieve the effect of improving speed and efficiency and expanding the scope of application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

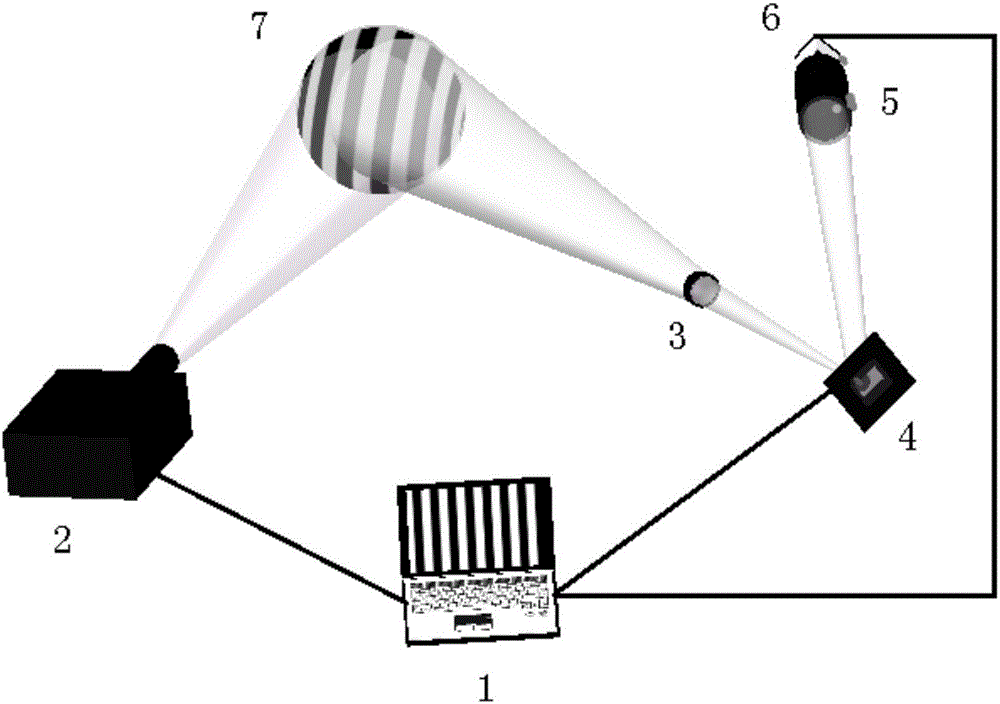

[0019] Such as figure 1 Shown, a kind of highly reflective surface three-dimensional measuring device based on digital micromirror, comprises computer 1, projector 2, first filter lens 3, digital micromirror 4, second filter lens 5, CCD camera 6, projector 2 connected to the computer 1, the light outlet of the projector 2 is aimed at the measured highly reflective surface 7, the first filter lens 3 and the digital micromirror 4 are sequentially placed on the reflected light path of the measured highly reflective surface 7, wherein the digital micromirror 4 is located on the transmitted light path of the first filter lens 3, and the digital micromirror 4 is also connected to the computer 1, and the second filter lens 5 and the CCD camera 6 are placed on the reflected light path of the digital micromirror 4 successively, and the CCD camera 6 The photosensitive element is located on the transmitted light path of the second filter lens 5 .

[0020] A three-dimensional measurement...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com