Electronic expansion valve with precision controlled through flow

An electronic expansion valve and flow control technology, which is applied in the direction of valve lift, valve details, valve devices, etc., can solve the problems of electronic expansion valve flow characteristics such as unsatisfactory linearity, unfavorable accurate flow control, and impossibility of accurate flow control. Facilitate system control and adjustment, eliminate lateral pressure, and improve flow control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solutions of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings.

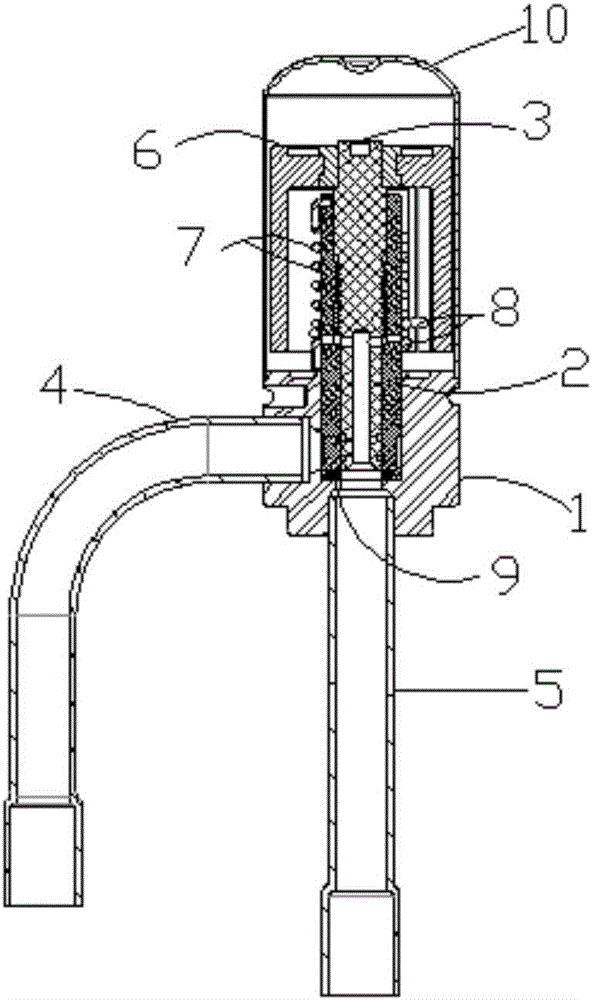

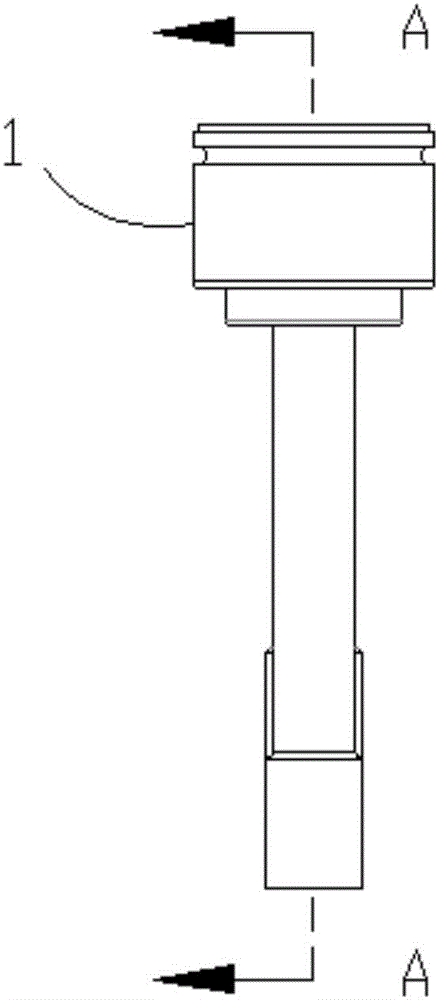

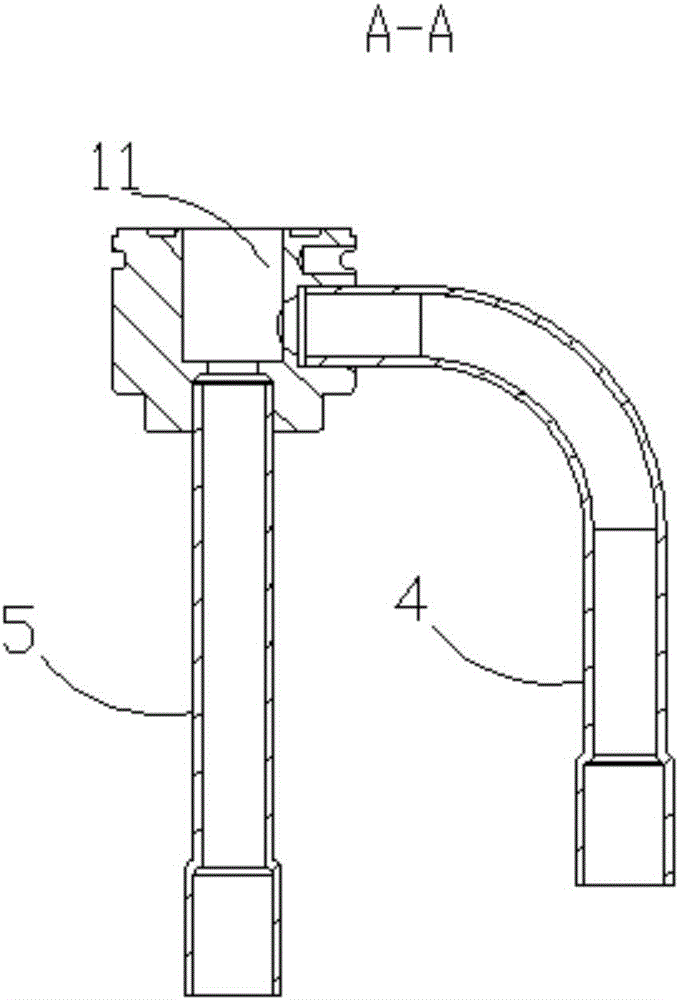

[0028] Such as figure 1 , figure 2 , image 3 , Figure 4 with Figure 5 As shown, an electronic expansion valve with flow control accuracy includes a valve seat 1 and a valve stem 3, and a through groove 11 is formed on the valve seat 1, and a matching bearing seat 2 is inserted into the through groove 11, The bearing seat 3 includes a seat body 23, and a through hole 21 is formed in the seat body 23, and the through hole 21 is matched with the valve stem 3, and an internal thread segment 24 is formed in the middle of the inner wall of the through hole 21. Weld the matching straight pipe 5 at the bottom end of the through groove 11, and the outer wall of the valve seat 1 is provided with a side hole communicating with the through groove 11, and the side hole is welded with a matching elbow pipe 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com