Novel active absorber based on PZT (piezoelectric ceramic)

An active shock absorber and shock absorber technology, applied in the field of vibration reduction, can solve the problems of inconspicuous damping effect, achieve high load-carrying capacity, improve support stiffness, and actively control the effect of damping characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. However, it can be understood that the following specific embodiments are only preferred technical solutions of the present invention, and should not be construed as limiting the present invention.

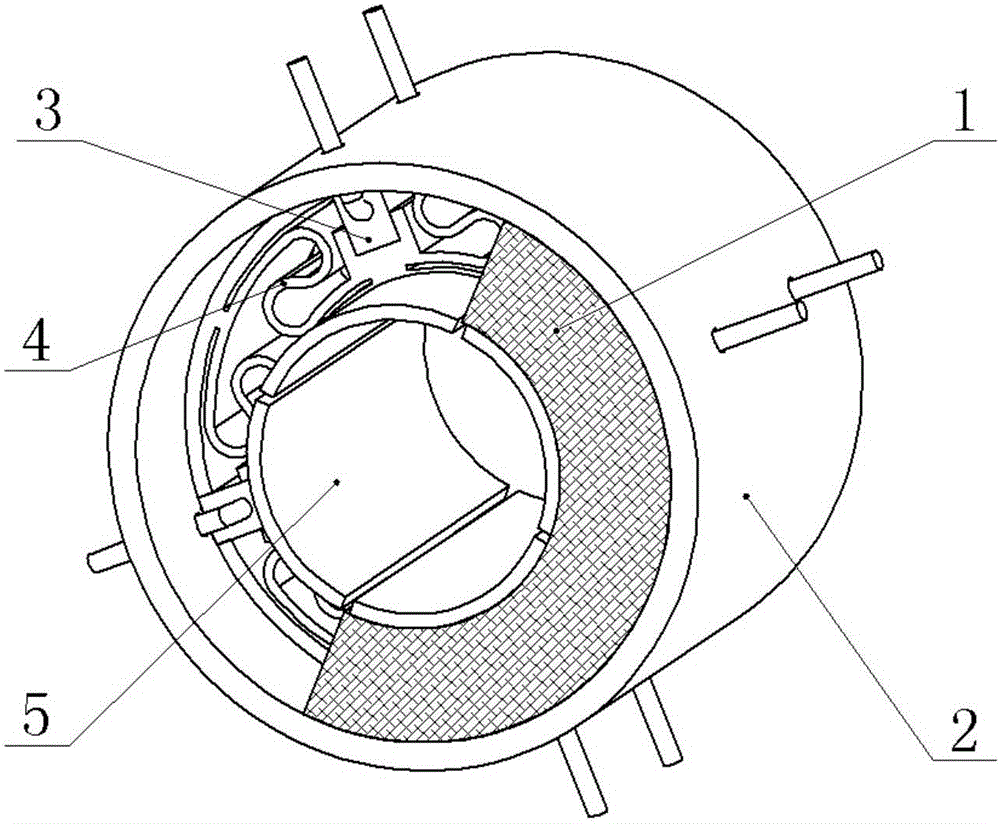

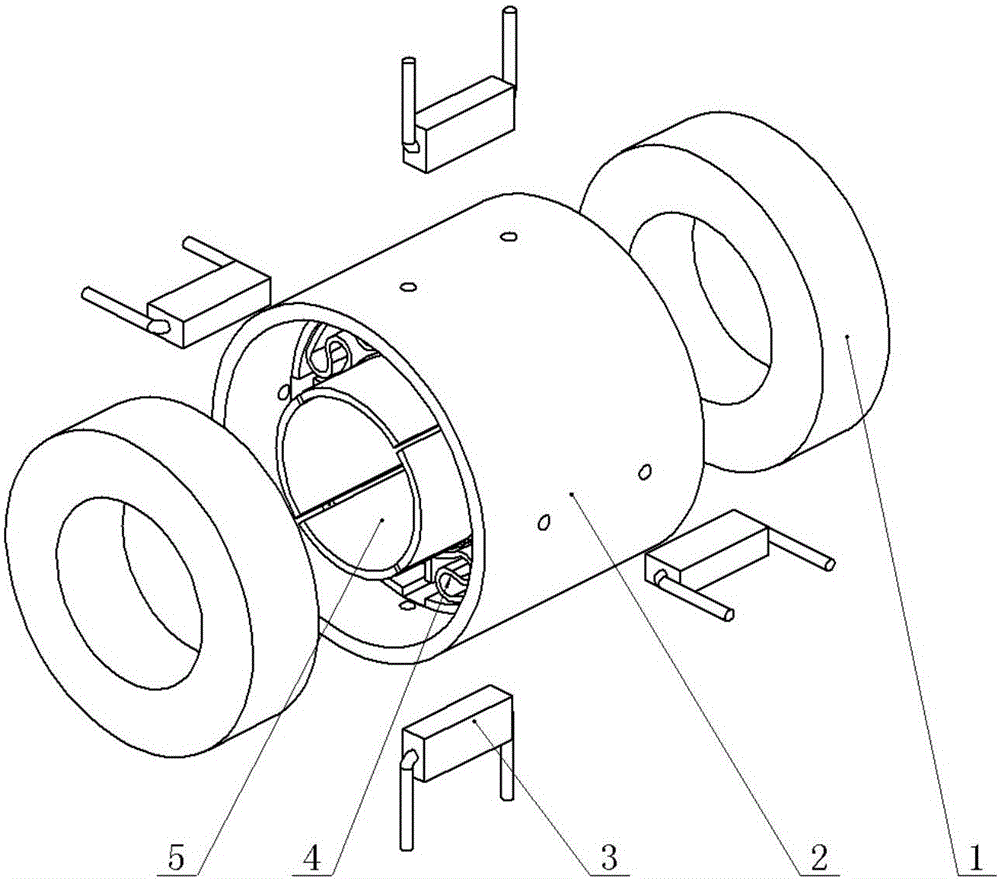

[0021] Such as figure 1 As shown, the new active shock absorber based on PZT includes outer bushing 2, elastic structure 4, pad 5, PZT 3 and metal rubber block 1. The outer shaft sleeve 2, the elastic structure 4, and the pad 5 are of an integrated structure. The PZT 3 is embedded in the groove between the two elastic structures 4 , and the metal rubber blocks 1 are installed in the grooves on both sides to support the tiles 5 in parallel.

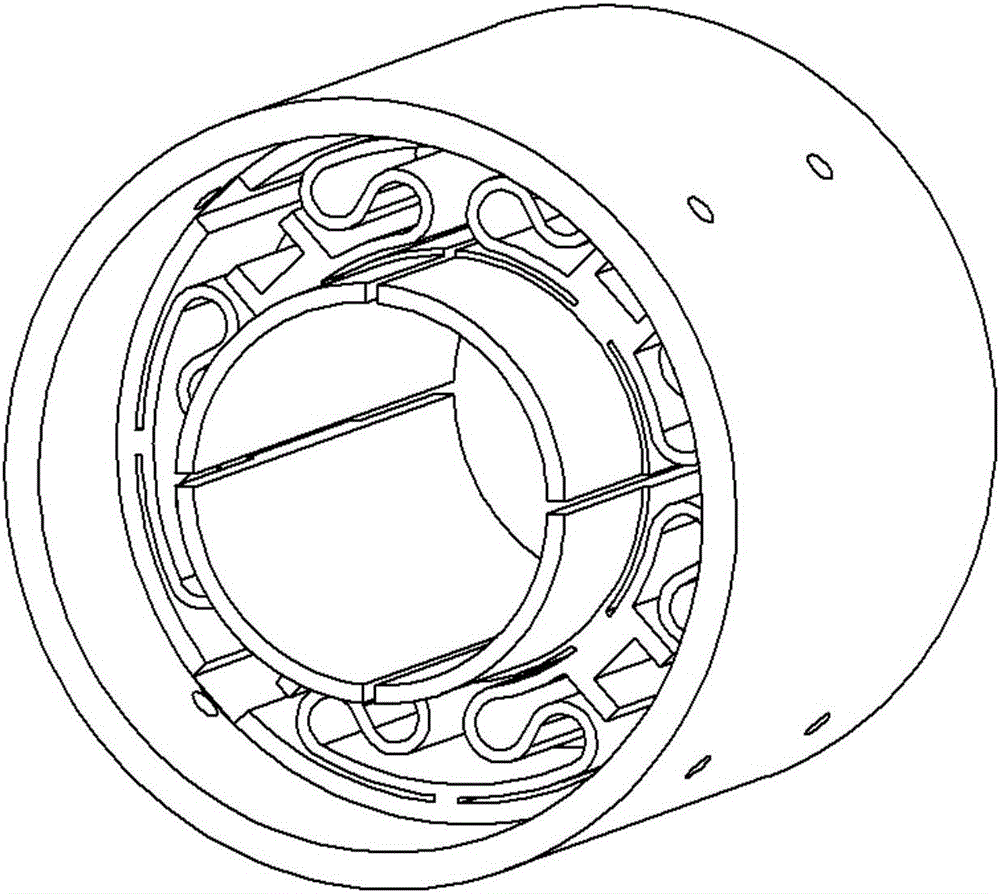

[0022] Such as Figure 4 As shown, the bushing is processed by CNC milling and WEDM, and the thickness of the elastic structure determines the rebound stiffness of the elastic structure. The radian ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com