Cooling system and control method thereof

A technology of a cooling system and a control method, which is applied in the control of coolant flow, cooling of the engine, fault prevention, etc., can solve the problems of large fan energy consumption, increased energy consumption of the whole machine, and energy waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

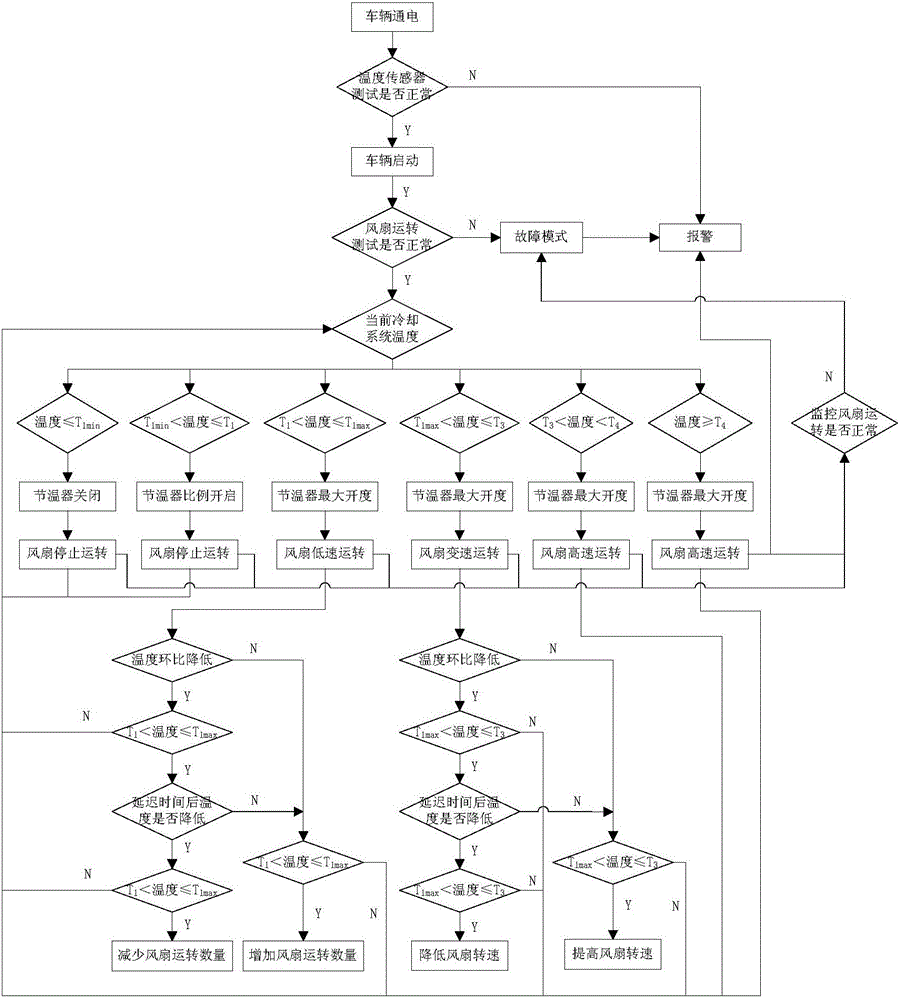

[0035] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

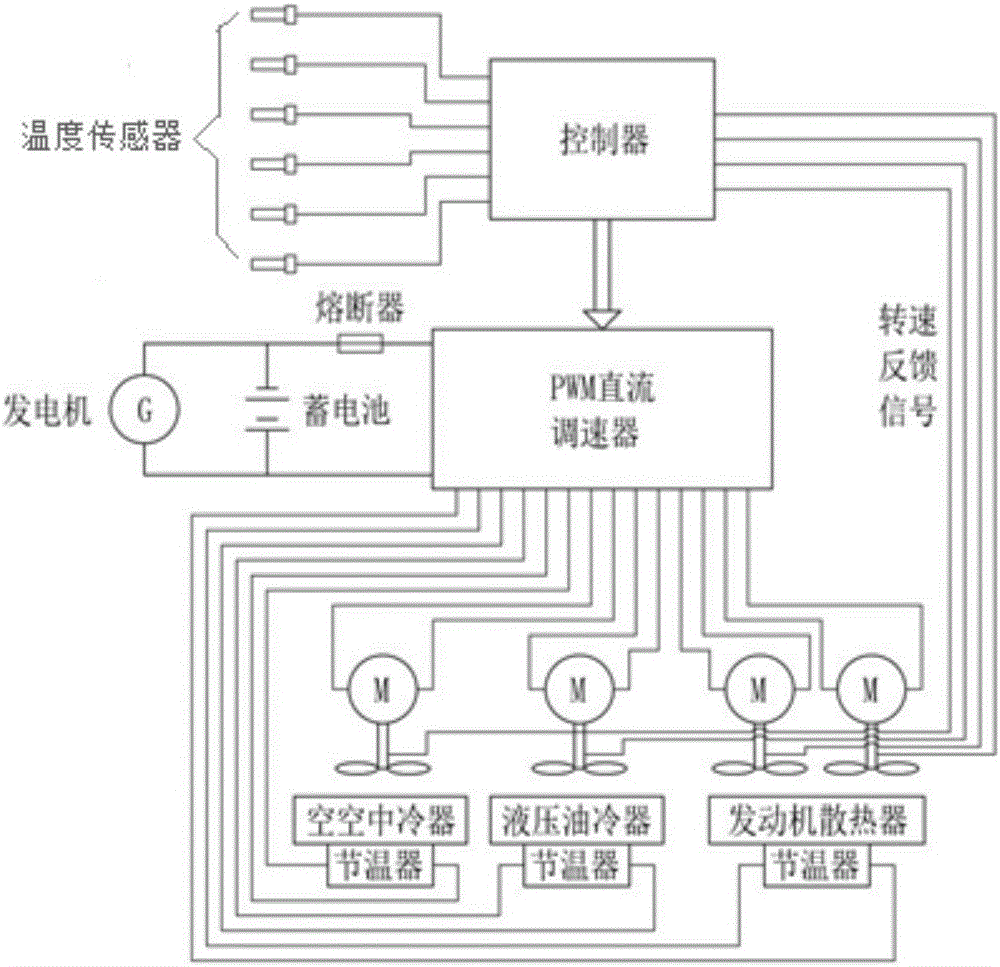

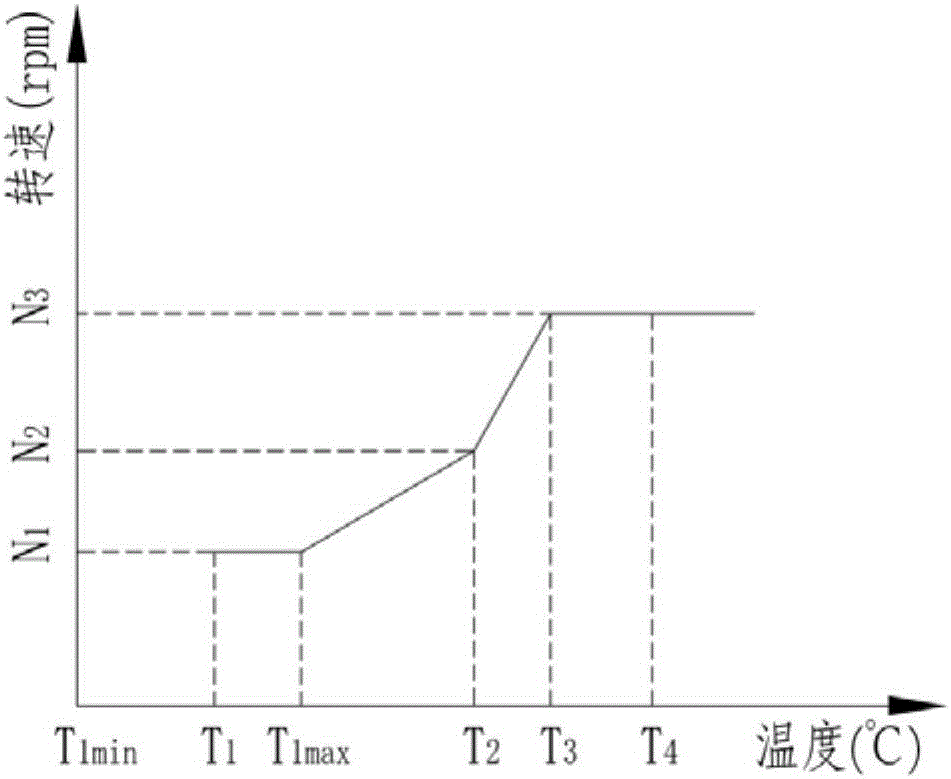

[0036] Such as figure 1 As shown, the present invention provides a cooling system, including a controller, a temperature sensor, a PWM DC governor, a thermostat, a fan and a speed sensor, wherein:

[0037] Each heat dissipation module is provided with an independent temperature sensor for detecting the temperature signal of the heat dissipation module. Each temperature sensor only acts on the fan of the corresponding heat dissipation module. In this embodiment, the heat dissipation module includes an engine radiator, Hydraulic oil cooler and air-to-air cooler, etc.;

[0038] The controller is connected to the temperature sensor, and the controller sends a control signal to the PWM DC speed controller connected to it through the temperature signal. Function, there is a fuse on the connection circui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com