Novel industrial type gas turbine brush gas seal and manufacturing method thereof

A gas turbine and industrial technology, applied in mechanical equipment, engine components, machines/engines, etc., can solve the problems of assembly difficulties, speed up the heat dissipation of components, and achieve the effect of reducing processing procedures, increasing overall strength, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

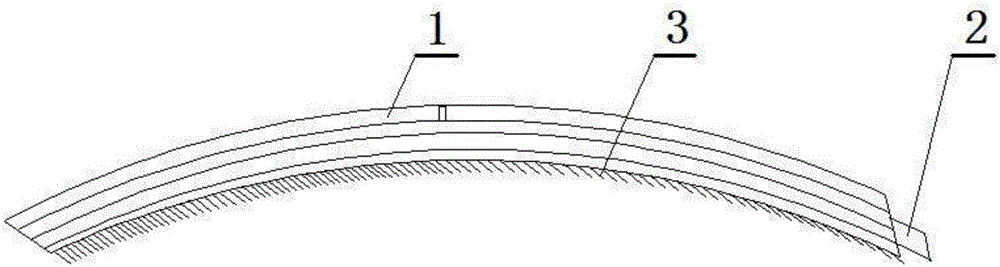

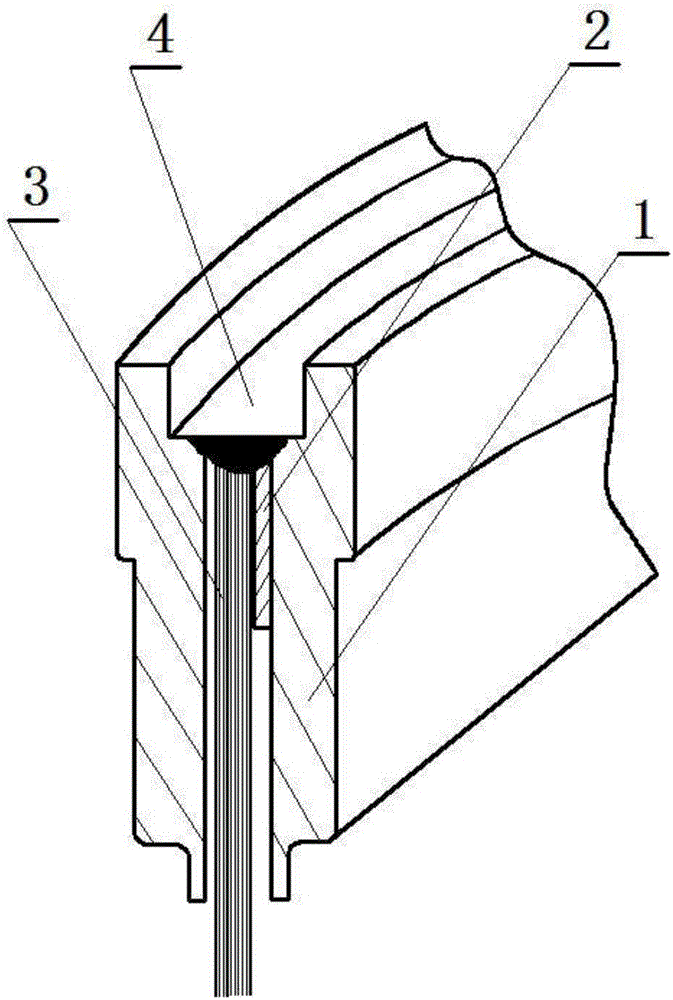

[0020] A new type of industrial gas turbine brush air seal, including: pressure plate main body 1, deflector 2, brush filament bundle 3, cooling tank main body 4; a new type of industrial gas turbine brush air seal has two upright ring-shaped The symmetrical pressure plate is welded at its top; the middle of the main body 1 of the pressure plate is provided with densely and evenly arranged brush bundles 3; the top of the main body 1 of the pressure plate is provided with a depressed cooling tank 4; A deflector 2 is provided on one side of the upper part.

[0021] A new type of industrial gas turbine brush gas seal, the manufacturing method steps are as follows:

[0022] Step 1) preparing a ring-shaped pressure bearing plate, a deflector, and trimming brush filament bundles;

[0023] Step 2) Clamping and positioning; clamp and fix the front and rear two individual pressure-bearing plates, deflectors, and brush wire bundles through the wire arrangement template to ensure that t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com