Treatment process and treatment system of lithium battery waste liquid

A treatment process, lithium battery technology, applied in precipitation treatment, multi-stage water treatment, water/sewage treatment, etc., can solve problems such as easy blockage of filter membranes, collapse of biochemical systems, excessive pollutants, etc., to improve biodegradability, Reduce the content of pollutants and reduce the effect of COD

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

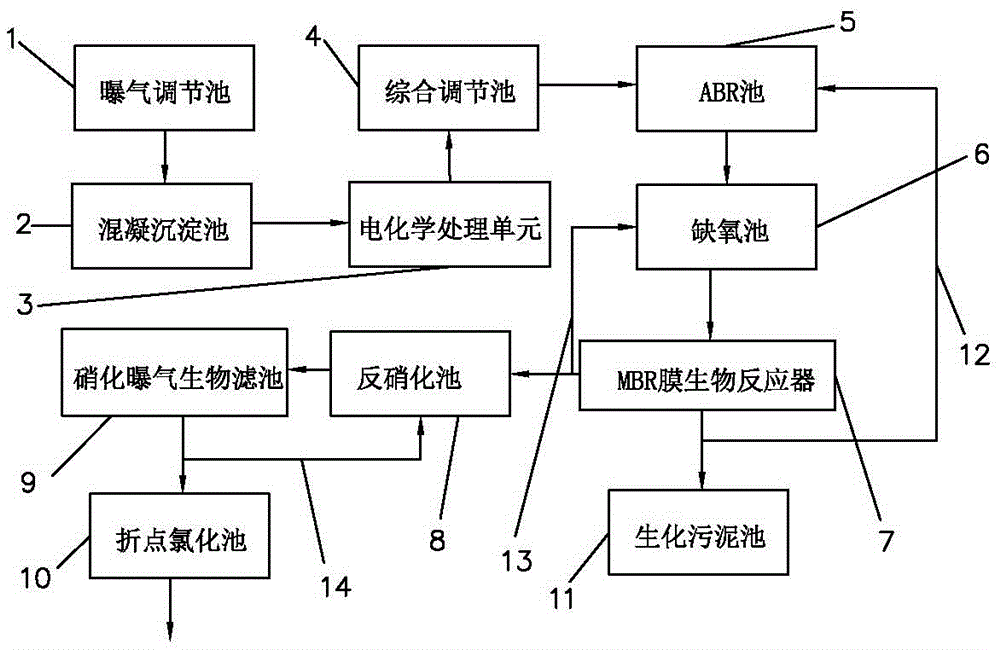

[0035] A treatment system used in the treatment process of lithium battery waste liquid, which sequentially includes an aeration regulating tank 1, a coagulation sedimentation tank 2, an electrochemical treatment unit 3, a comprehensive regulating tank 4, and an ABR tank 5 according to the flow direction of the lithium battery waste liquid , anoxic tank 6, MBR membrane bioreactor 7, denitrification tank 8, nitrification biological aerated filter tank 9, breakpoint chlorination tank 10;

[0036] The MBR membrane bioreactor 7 is provided with a sludge outlet, and a sludge return channel 12 is provided between the sludge outlet and the ABR pool 5, and the sludge outlet is also connected with a biochemical sludge pool 11, and the MBR Between the water outlet of the membrane bioreactor 7 and the water inlet of the anoxic tank 6, a first backflow channel 13 for lithium battery waste liquid is provided;

[0037] A second backflow channel 14 for lithium battery waste liquid is provide...

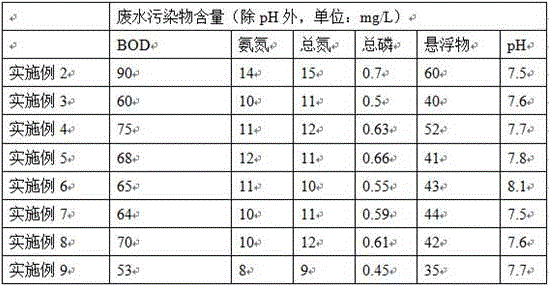

Embodiment 2

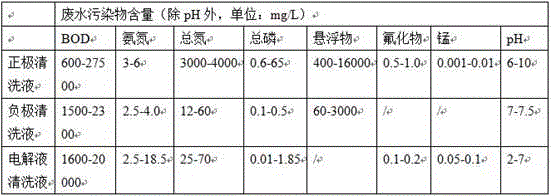

[0039] A treatment process for lithium battery waste liquid, comprising the steps of:

[0040] (1) Electrochemical treatment: the lithium battery waste liquid is introduced into the electrochemical treatment unit for electrocoagulation reaction; the electrochemical treatment unit triggers the electrocoagulation reaction through the bipolar plates powered by DC pulses, and the voltage between the two polar plates is 60V, The pole distance is 5cm, the pulse frequency is 7kHz, and the electrocoagulation reaction time is 2h;

[0041] (2)A 2 / O treatment: the lithium battery waste liquid after electrochemical treatment is introduced into anaerobic tank, anoxic tank and aerobic filter device sequentially, and the aerobic filter device is an MBR membrane bioreactor; the MBR membrane bioreactor and A sludge return channel is provided between the anaerobic tanks, the sludge return ratio from the MBR membrane bioreactor to the anaerobic tank is 50%, and between the outlet of the MBR me...

Embodiment 3

[0044] A treatment process for lithium battery waste liquid, comprising the steps of:

[0045] Step A pretreatment: the lithium battery waste liquid is introduced into the aeration regulating tank 1 and the coagulation sedimentation tank 2 in sequence, aeration and stirring are carried out in the aeration regulating tank, the aeration gas water ratio is 4:1, and the residence time is 15h .

[0046] (1) Electrochemical treatment: the lithium battery waste liquid is introduced into the electrochemical treatment unit 3 for electrocoagulation reaction; the electrochemical treatment unit 3 triggers the electrocoagulation reaction through the bipolar plates powered by DC pulses, and the voltage between the two polar plates is 60V, pole distance 6cm, pulse frequency 8kHz, electrocoagulation reaction time 2.5h;

[0047] Adding nutrients in step B: introduce the electrochemically treated lithium battery waste liquid into the comprehensive adjustment pool 4, and put solid organic nutri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com