Process and device for producing strong ammonia water through negative pressure operation

A concentrated ammonia water and negative pressure technology, which is applied in the preparation/separation of ammonia, ammonia compounds, inorganic chemistry and other directions, can solve the problems of low vacuum degree, the bottom temperature of the ammonia distillation tower, the limited degree of negative pressure, and unfavorable energy-saving operation, etc. Achieve the effect of weakening corrosion performance, reducing requirements and avoiding low vacuum

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

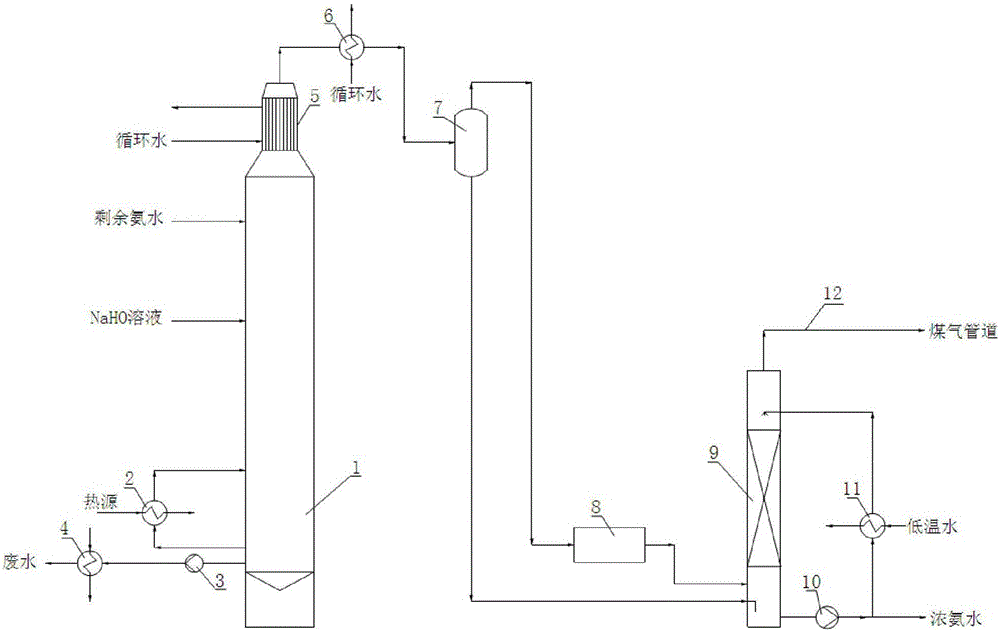

[0028] The specific embodiments of the present invention will be further described below in conjunction with the drawings:

[0029] Such as figure 1 As shown, a process for producing concentrated ammonia under negative pressure operation includes the following steps:

[0030] 1) The remaining coking ammonia water and NaOH solution are directly sent to the ammonia distillation tower 1 for the ammonia distillation operation;

[0031] 2) The waste water at the bottom of the ammonia distillation tower 1 is heated by the heat source in the reboiler 2, and the temperature of the waste water enters the bottom of the ammonia distillation tower 1 for reduced pressure flash evaporation, providing a steam heat source for the ammonia distillation operation; the waste water at the bottom of the tower enters by the wastewater pump 3 Waste water cooler 4, discharge waste water;

[0032] 3) The ammonia vapor from the ammonia distillation tower 1 divider 5 enters the condenser 6 to cool and partially...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com