Steel-plate electric flat carriage control device

An electric flat car and control device technology, applied in the direction of AC induction motor traction, etc., can solve the problems of poor insulation, large grounding voltage drop, and high electrical failure rate, and achieve simple and controllable lines, less voltage drop, and easy operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention is described in further detail now in conjunction with accompanying drawing.

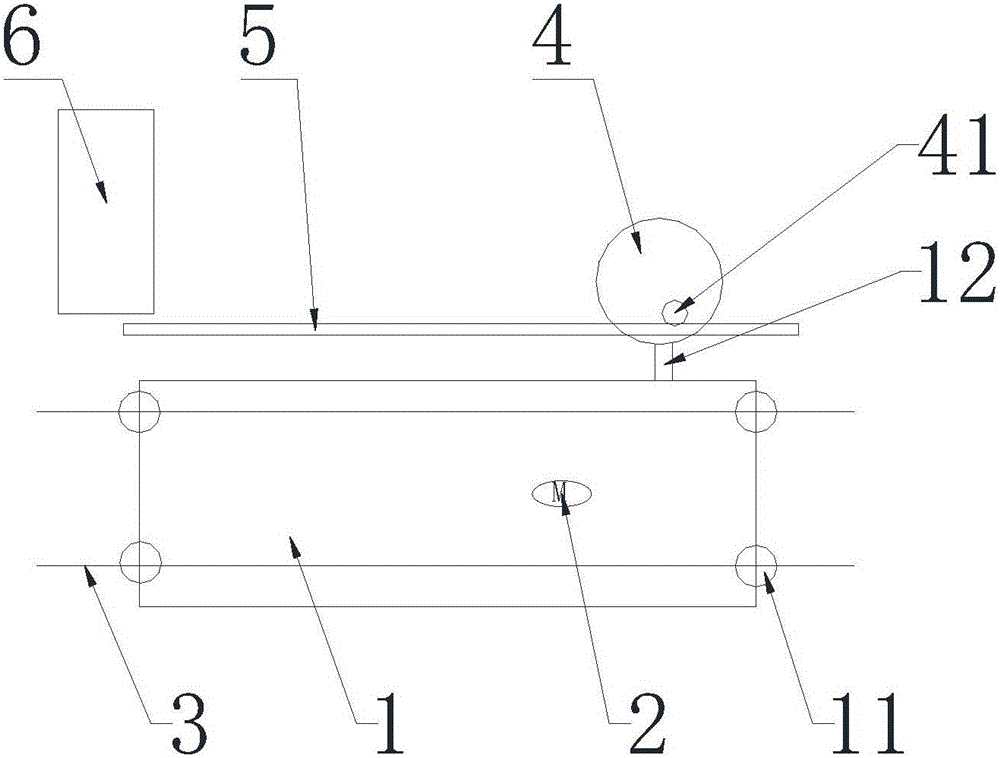

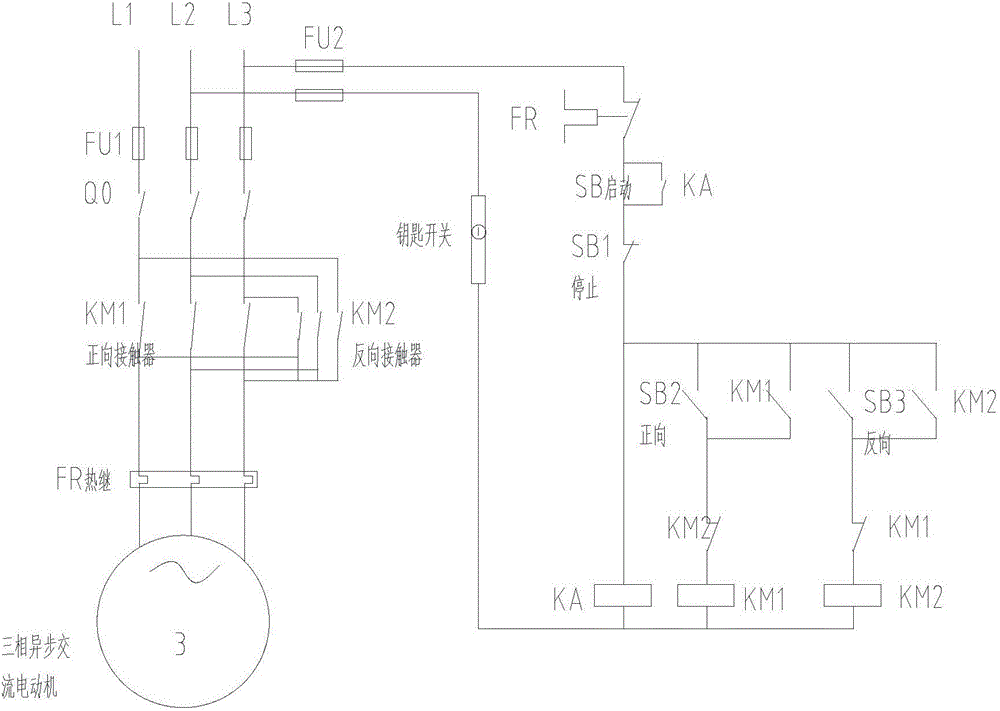

[0015] according to Figure 1 to Figure 3 The control device for a steel plate electric flat car includes an electric flat car 1, a track 3, and cables. The electric flat car 1 is assembled on the track 3 through wheels 11. The cable trench 5 is placed in the cable trench 5, and a cable bridge is placed in the cable trench 5. One end of the electric flat car 1 is provided with a steel structure support 12, and a spring type cable reel 4 is provided on the steel structure support 12. One end of the cable is connected to the distribution cabinet 6, the three-phase electrical connection, the free end of the cable is wound in the cable reel 4, after the rotating slip ring 41 of the cable reel 4 is exposed, it is electrically connected with the three-phase AC asynchronous motor 2, so that the electric flat car 1 moves During the process, the cable wound in the cable reel 4 c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com