Sliding table-adaptive adjusting mechanism of hole turning machine

A technology of adjusting mechanism and sliding table, applied in the field of turning machine, can solve the problems of not making too much improvement in the stability of the guide rail, low energy loss, etc. Smooth horizontal motion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with accompanying drawing:

[0015] The directional terms mentioned in the following examples, such as

[0016] "Up, down, left, and right" refer only to the directions of the drawings, therefore, the directional terms used are for illustration and not for limiting the present invention.

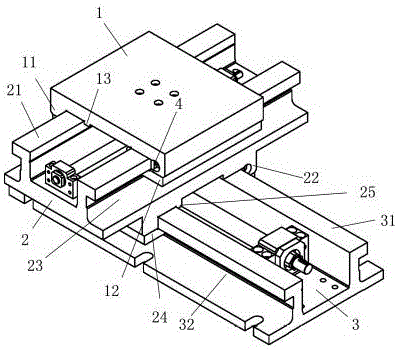

[0017] Such as Figure 1-2 As shown in the figure, an adjustment mechanism for the sliding table of a lathing machine includes an upper slide plate 1, a middle slide plate 2 and a slide base 3. The upper slide plate 1 and the middle slide plate 2 pass through the first guide rail 21 are connected to each other, the slide plate 2 in the slide table and the slide table base 3 are connected to each other through the second guide rail 31, the first guide rail 21 and the second guide rail 31 are perpendicular to each other, and the two sides of the slide plate 1 on the slide table are respectively provided with There is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com