A bean polishing machine

A technology of polishing machine and beans, which is applied in grain finishing, grain degerming, agriculture, etc. It can solve the problems of inability to carry out large-scale market promotion and application, high production and use costs, and poor treatment effect, etc., to achieve the goal of removing Impurities and mildew, low production cost, high polishing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

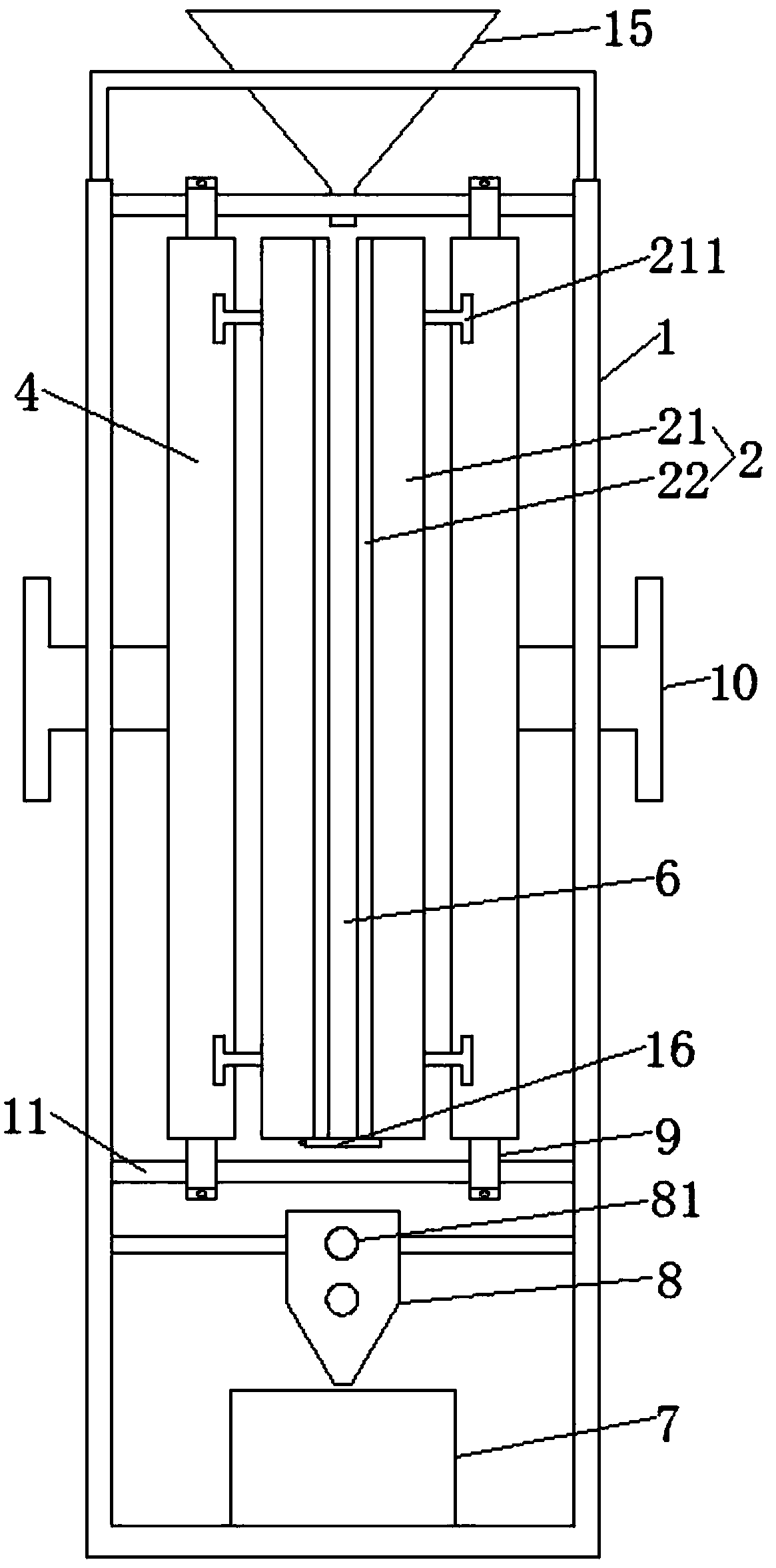

[0037] Example: such as figure 1 with 2 As shown, the bean polishing machine of the present embodiment includes a frame 1, two polishing plates 2, two driving devices 3 and two slide seats 4;

[0038] The two above-mentioned sliding seats 4 are installed vertically and parallelly in the above-mentioned frame 1;

[0039] The two above-mentioned polishing plates 2 are all arranged vertically, and are arranged in one-to-one correspondence with the above-mentioned sliding seats 4. The above-mentioned polishing plates 2 are respectively slidably installed on the sides of the corresponding above-mentioned sliding seats 4 that are close to each other, and can be moved along the corresponding above-mentioned sliding seats respectively. 4 horizontal sliding;

[0040] There is a gap between the two above-mentioned polishing plates 2, and their two sides are respectively sealed and connected by a flexible belt 5, and a polishing chamber 6 that is open up and down is formed between the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com