Boiler flue gas recirculation dehumidification device

A boiler flue gas and recirculation technology, applied in gas treatment, membrane technology, dispersed particle separation, etc., can solve problems such as safety hazards, achieve the effect of small pressure loss, eliminate safety hazards, and high dehumidification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with drawings and embodiments.

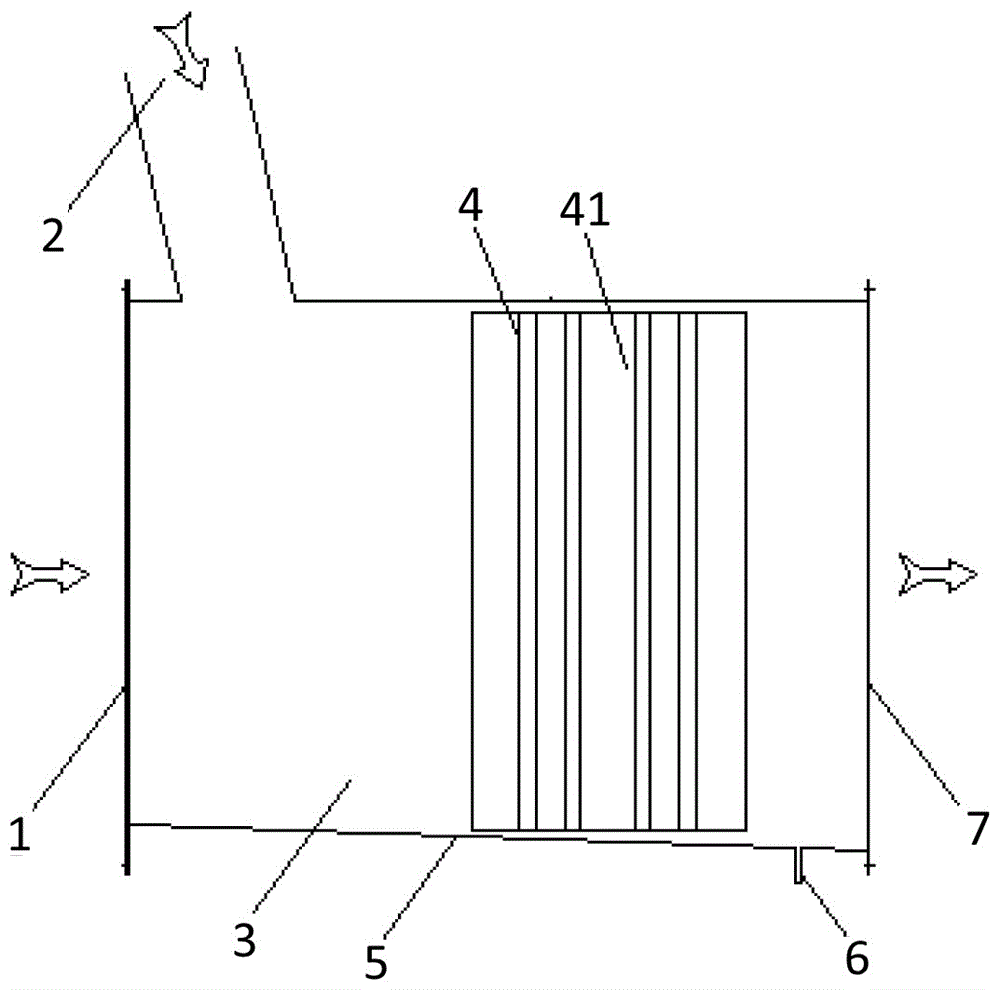

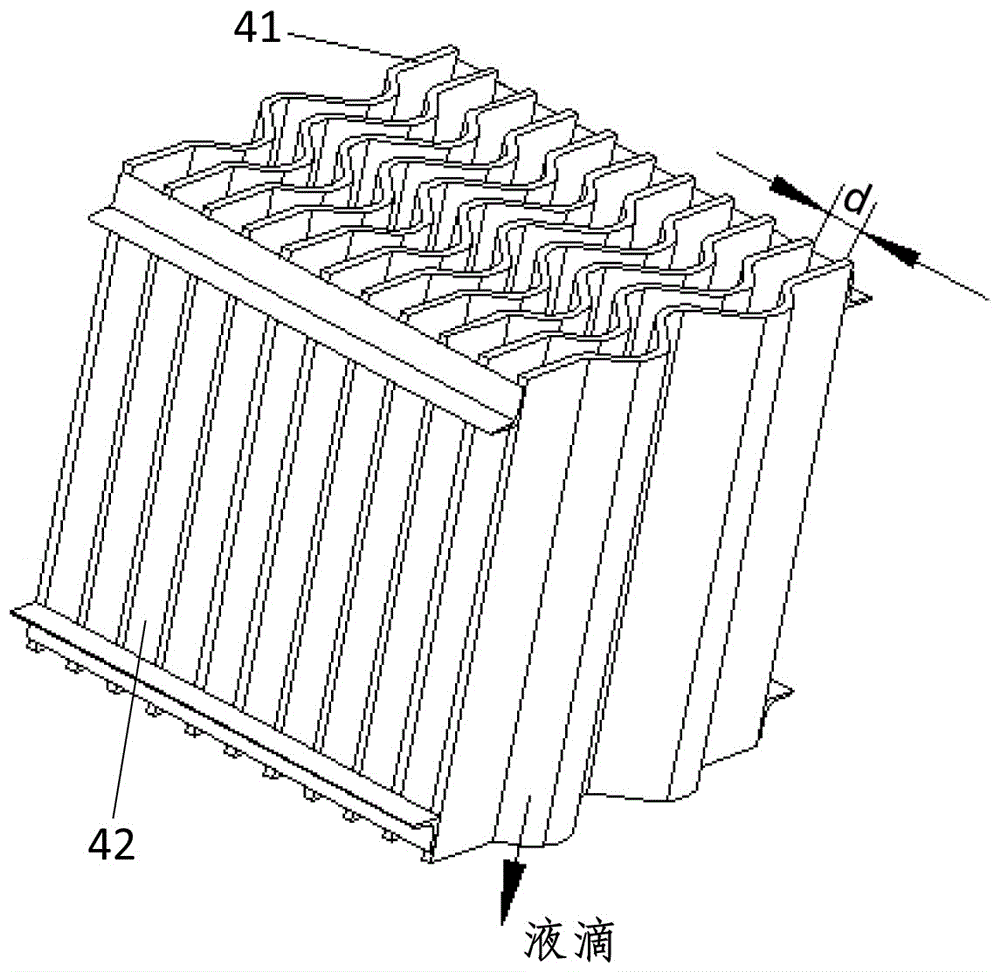

[0015] figure 1 It is a schematic diagram of the overall structure of the dehumidification device of the present invention. It can be seen from the diagram that a boiler flue gas recirculation dehumidification device includes a flue gas mixing box 3, a combustion air inlet 1 located at the head end of the flue gas mixing box 3, and The upper side wall of the head end of the flue gas mixing box 3 is obliquely inserted into the hot flue gas inlet pipe 2 in the inner cavity of the flue gas mixing box 3, and the mixed gas outlet 7 located at the tail end of the flue gas mixing box 3 is characterized in that: A mist eliminator 4 is fixedly installed in the middle and rear of the flue gas mixing box 3; the mist eliminator 4 is composed of a plurality of baffles 41 parallel to each other, arranged longitudinally, and leaving intervals 42(d) between them. The interval 42(d) be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com