Daily-use tissue production equipment

A technology for producing equipment and household paper, which is applied to household appliances, layered products, lamination devices, etc., can solve the problems of skin discomfort, poor paper smoothness, users questioning the quality of household paper, etc., and achieves increased wiping. area, increased bulk, and improved cleaning performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

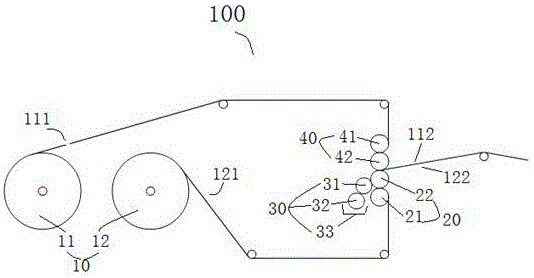

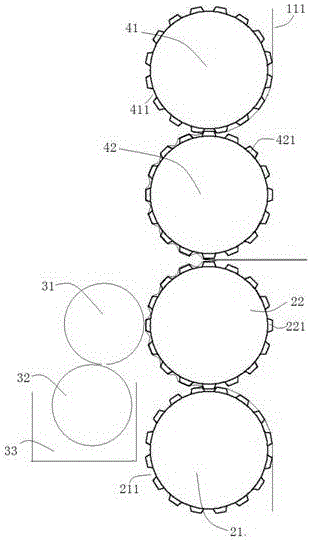

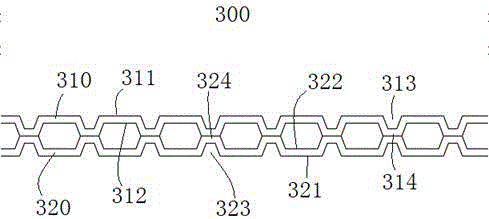

[0022] Please also see figure 1 and figure 2 , the household paper production equipment 100 provided by the first embodiment of the present invention includes an unwinding device 10 , a lower paper embossing roll set 20 , a sizing roll set 30 and an upper paper embossing roll set 40 .

[0023] The unwinding device 10 includes an upper paper unwinding roller 11 and a lower unwinding roller 12, the upper paper unwinding roller 11 is wound with an upper base paper 111, and the lower unwinding roller 12 is wound with a lower base paper 121.

[0024] In this embodiment, the number of the upper paper unwinding roller 11 and the lower layer unwinding roller 12 is one respectively, and the upper layer base paper 111 respectively released by the upper layer paper unwinding roller 11 and the lower layer unwinding roller 12 And the lower base paper 121 is single-layer base paper.

[0025] It can be understood that the upper layer paper unwinding roller 11 can be one or more, and the u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com