Method of using liquorice root for cigarette generation after liquorice root primary processing

A technology for licorice and cigarettes, applied in the field of tobacco products, can solve the problems of unacceptable and difficult to obtain silk products for consumers, etc., achieves good promotion and application prospects, reduces the smell of medicinal herbs, and improves the effects of smoking quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Application of licorice shreds in cigarette "H" brand

[0024] (1) Sample making

[0025] Weigh 100 parts of licorice slices by weight, add 400 parts of 70% ethanol and extract once at 90°C for 2 hours, then separate the solid and liquid, and the solid matter after the solid-liquid separation is to extract the licorice slices once, and dry to the moisture content 40±3%, use a tablet machine for tableting, collect licorice flakes, bake until the moisture content is 20±3%, cut into shreds with a shredder, and then use a 30-mesh sieve to remove particles and powder. Bake until the moisture content is 12±3%, and finally obtain the desired silk product. Add in an amount of 5‰ of the mass of shredded tobacco leaf group of "H" brand cigarette, and mix evenly.

[0026] (2) Implementation effect

[0027] The quality of the obtained silk products was accurately weighed with a Mettler MS204S electronic balance. Calculated in parts by weight, 100 parts of licorice slices as a r...

Embodiment 2

[0034] Application in cigarette "H" brand

[0035] Repeat Example 1, with the following differences:

[0036] (1) Sample making

[0037] Weigh 100 parts of licorice slices by weight, add 400 parts of 70% ethanol and extract once at 90°C for 3 hours.

[0038] (2) Implementation effect

[0039] The quality of the obtained silk products was accurately weighed with a Mettler MS204S electronic balance. Calculated in parts by weight, 100 parts of licorice tablets as a raw material yielded 76.14 parts of silk products, and the obtained result is the average value of five experimental results. The moisture content of the raw material licorice sheet and the obtained silk product is all controlled at 12±3%. The silk yield is 76.14%.

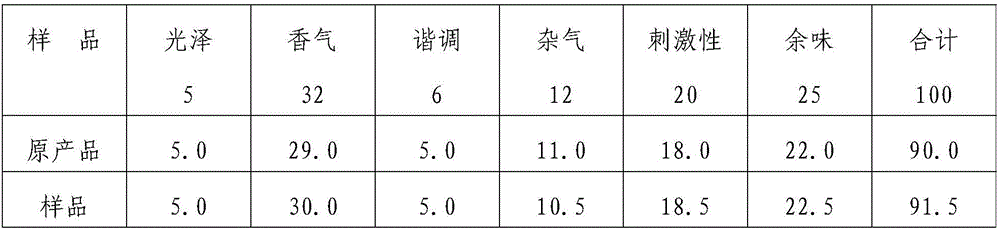

[0040] Sensory evaluation of cigarettes added with the shredded licorice product for tobacco: it has the advantages of sweet aftertaste, mellow smoke, and coordinated smoke aroma. See Table 2 for evaluation and comparison.

[0041] Table 2 Sensory...

Embodiment 3

[0045] Application in cigarette "H" brand

[0046] Repeat Example 1, with the following differences:

[0047] (1) Sample making

[0048] Weigh 100 parts of licorice slices by weight, add 400 parts of 70% ethanol and extract once at 90°C for 4 hours.

[0049] (2) Implementation effect

[0050] The quality of the obtained silk products was accurately weighed with a Mettler MS204S electronic balance. Calculated in parts by weight, 100 parts of licorice slices as a raw material yielded 74.59 parts of silk products, and the obtained result is the average value of five experimental results. The moisture content of the raw material licorice sheet and the obtained silk product is all controlled at 12±3%. The silk yield is 74.59%.

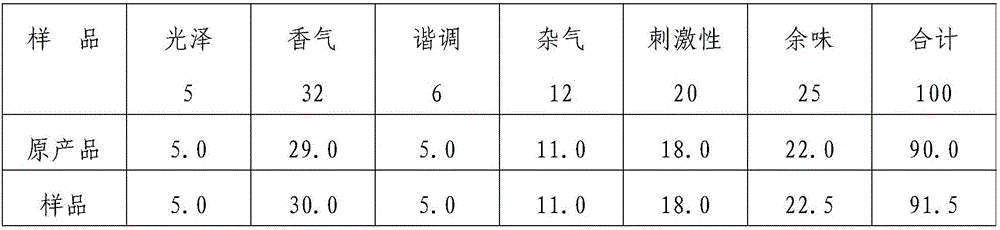

[0051] Sensory evaluation of cigarettes added with the shredded licorice product for tobacco: it has the advantages of sweet aftertaste, mellow smoke, and coordinated smoke aroma. See Table 3 for evaluation and comparison.

[0052] Table 3 Sensory ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com