rail vehicle

A technology for rail vehicles and vehicle units, applied in the field of rail vehicles, can solve problems such as inability to achieve safety integrity, and achieve the effects of saving switching elements, simplifying wiring, and avoiding consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

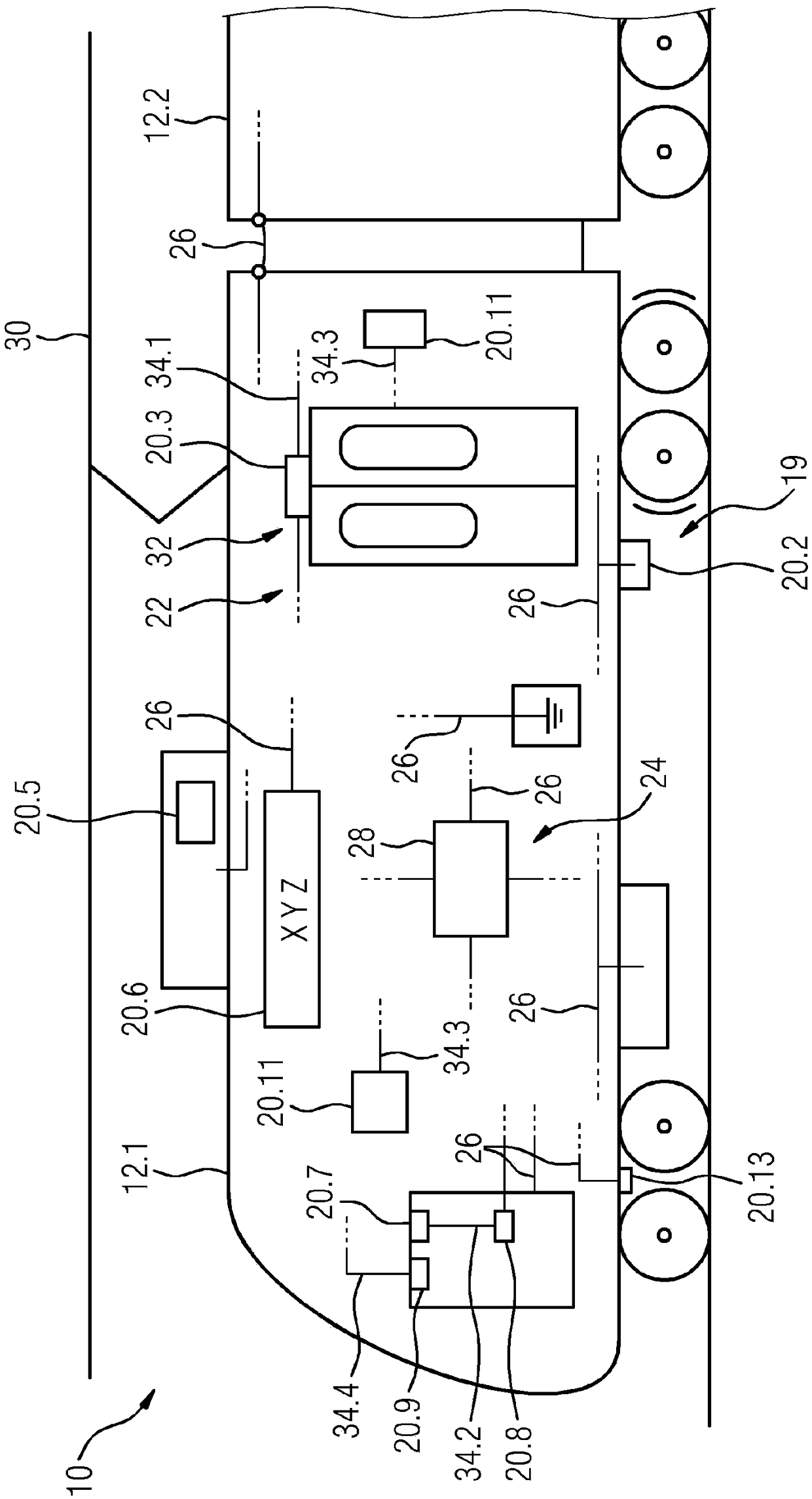

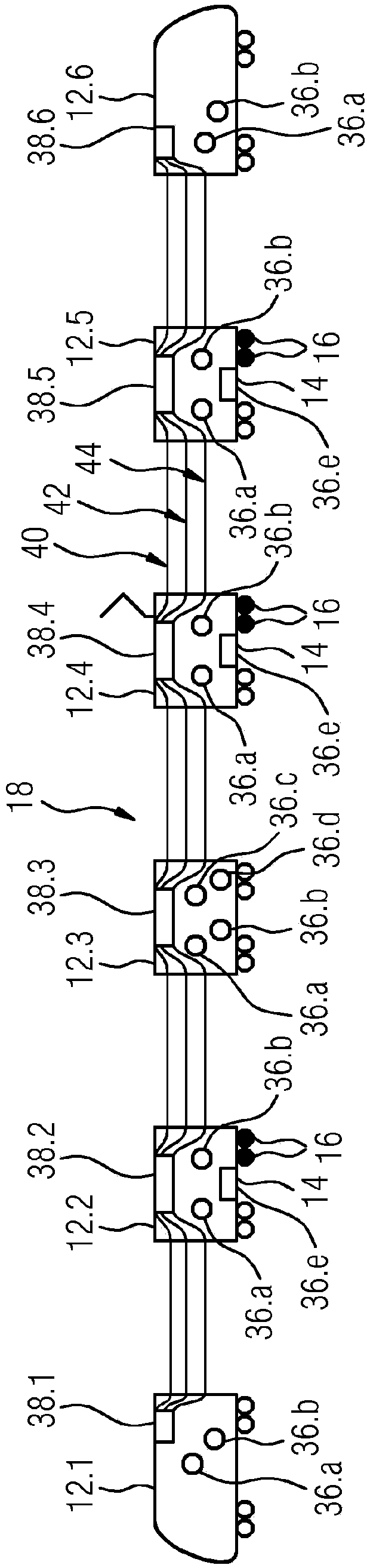

[0039] figure 1 A schematic side view of the rail vehicle 10 is shown. The rail vehicle 10 is formed as a consist of a plurality of vehicle units 12 . To this end, at least one of the vehicle units of the consist is provided with a drive unit 14 for driving at least one drive shaft 16 (see figure 2 ). In another embodiment, it is conceivable that the rail vehicle 10 is designed as a separate train. Furthermore, the rail vehicle 10 can have a group of undriven passenger carriages, which are coupled to at least one motor vehicle, for example a locomotive.

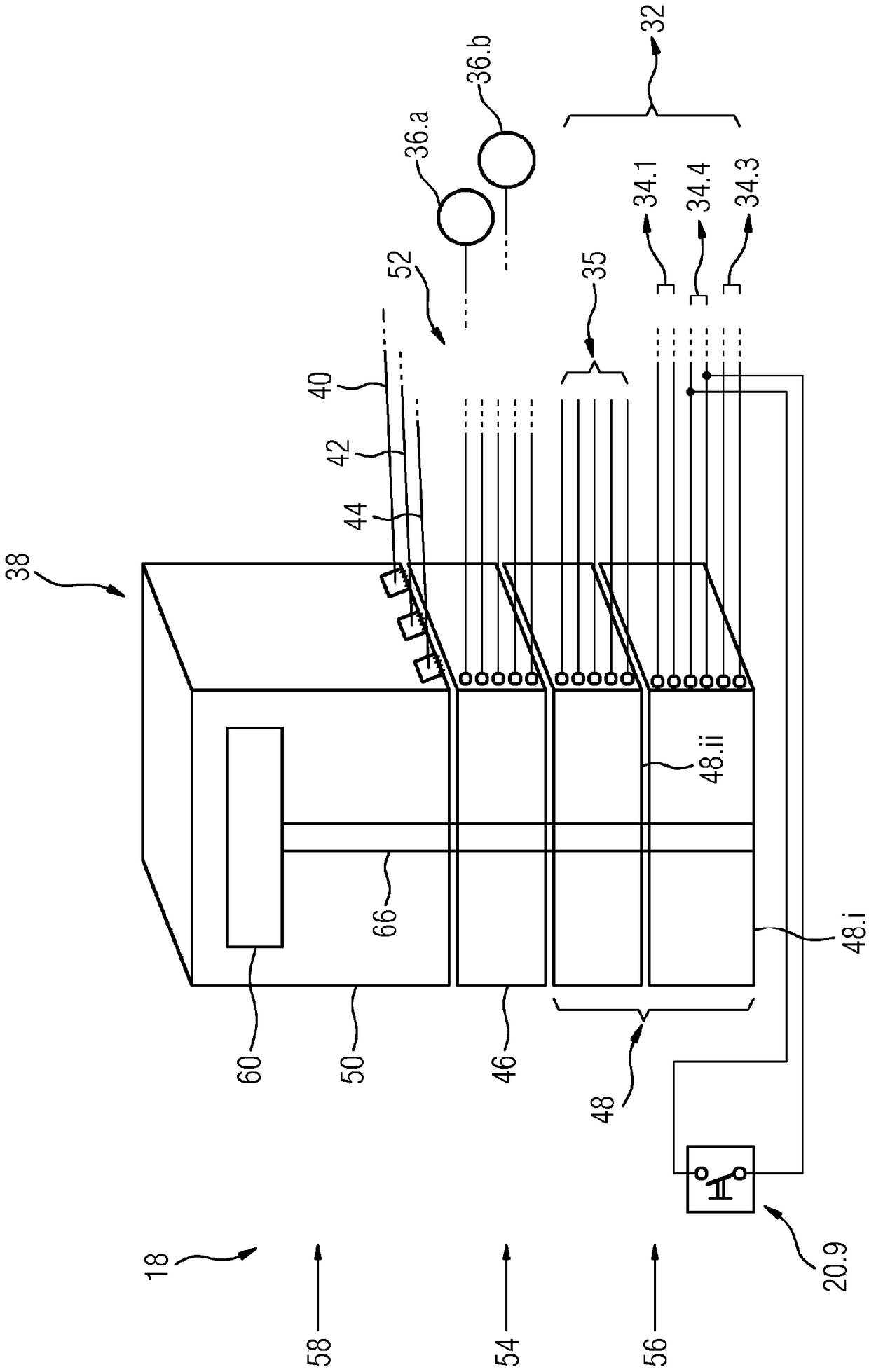

[0040] It is known that the rail vehicle 10 has a plurality of running gears which enable the rail vehicle 10 to be operated. In particular, the actuator can be designed as a control unit, a sensor unit and / or an actuator unit. The running mechanism installed in the rail vehicle 10 and then permanently engaged on the vehicle structure by means of Figures 2 to 6 The guidance systems 18 shown in detail in are networked ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com