A kind of ultraviolet light curing pipe material manufacturing process

A manufacturing process and ultraviolet light technology are applied in the field of trenchless pipeline repair, which can solve the problems of inconvenient road traffic and low efficiency, and achieve the effects of convenient construction, simple preparation method and excellent wear resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5

[0026] A manufacturing process of ultraviolet light curing pipeline material, comprising the following steps:

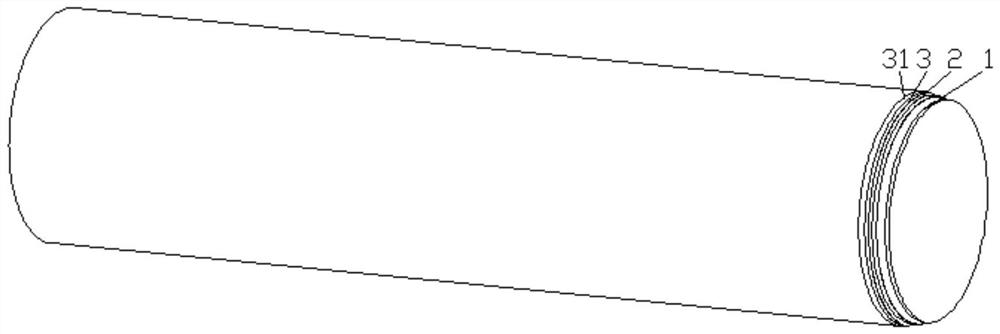

[0027] (1), dry material laying: using a laying and folding machine to lay out and laminate in the order of inner film 1, glass fiber 2, outer film 3, and non-woven fabric 31 from bottom to top to form dry material semi-finished products; the inner film and outer film The film is made of transparent adhesive material with single-sided adhesive and double-sided adhesive respectively;

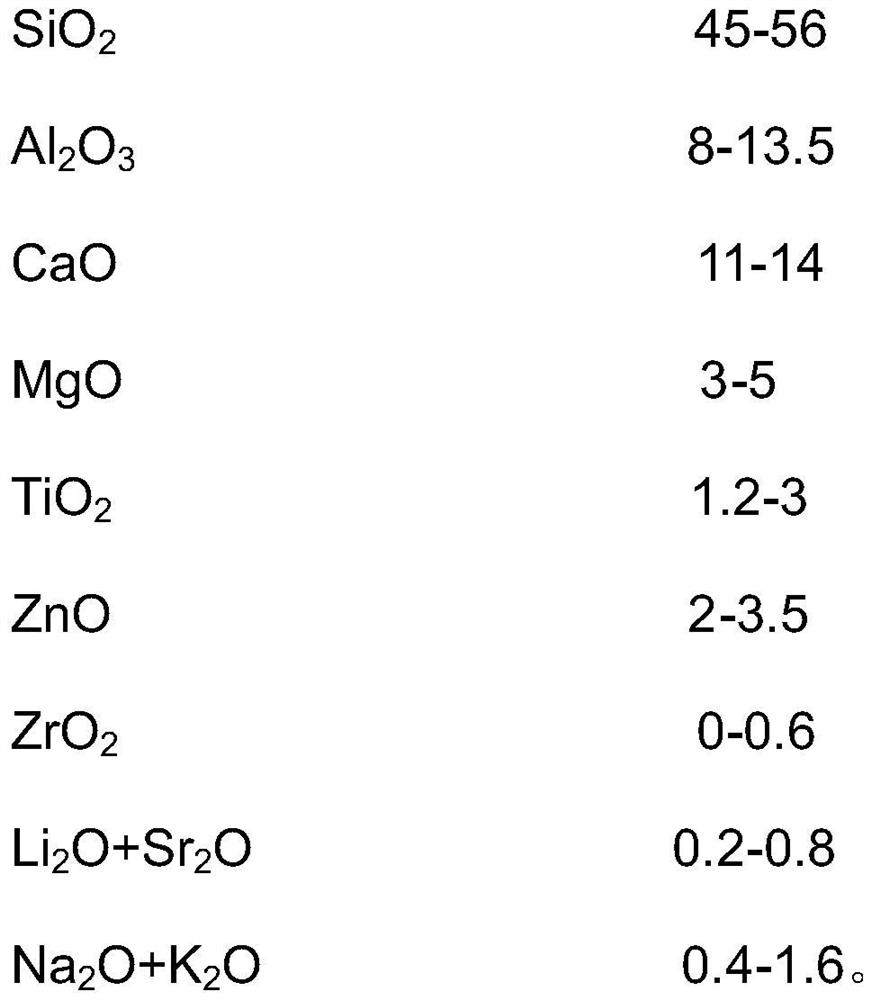

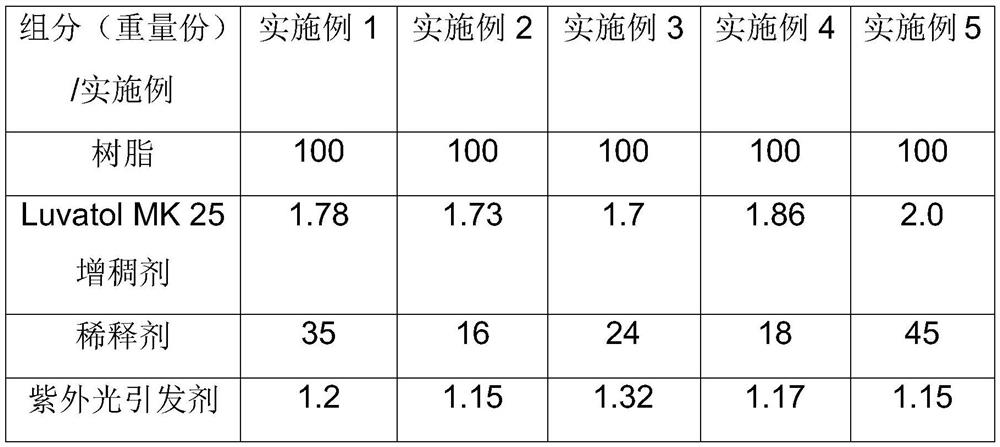

[0028] (2), impregnation liquid ingredients: resin, thickener, diluent, ultraviolet photoinitiator are compounded into impregnation liquid in mixing container, standby; Said diluent is reactive diluent with respect to described resin;

[0029] (3) Impregnation: In a closed container, use a vacuum pump to pump to a relative vacuum higher than -30mbar; fill the impregnating liquid into the gap between the layers of the semi-finished dry material, so that the impregnating liquid and the se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com