Method for producing acoustic damping elements

An attenuating element, acoustic technology, applied in electrical components, sounding equipment, sensor parts, etc., can solve the problems of reproducibility, manufacturing cost and pollution process duration, achieve short development or processing time, small tolerance range, The effect of reducing the number of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

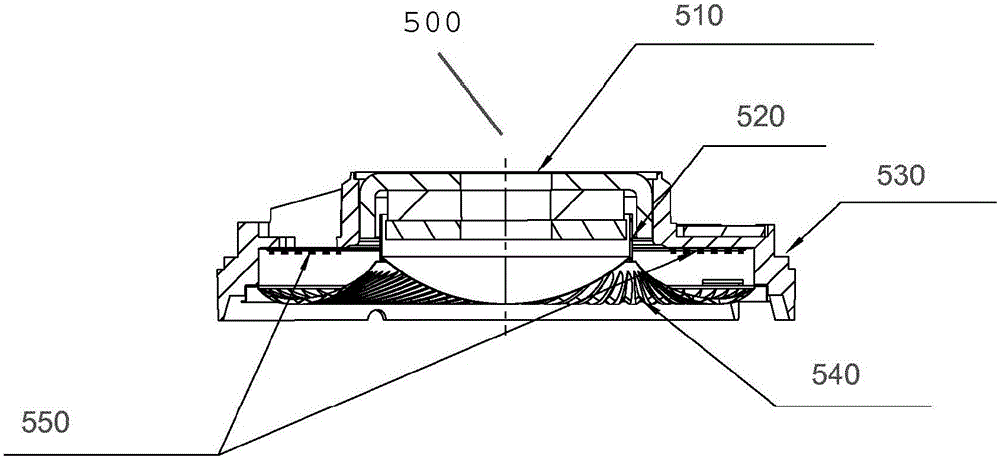

[0023] figure 1 A schematic cross-section of an electroacoustic transducer according to the invention is shown. The converter is designed, for example, as an earphone housing. Acoustic attenuation elements can be incorporated in the earphone housing. The coil 520 through which the current flows freely oscillates within the magnetic field generated by the electromagnetic system 510 and thus drives the membrane 540 fixedly connected thereto. Due to its mass and the spring stiffness of the membrane 540 , the system forms a freely oscillating spring-mass system, which has to be damped. This is done by means of an acoustic attenuation device 550 placed on the membrane 540, typically by means of a perforated membrane.

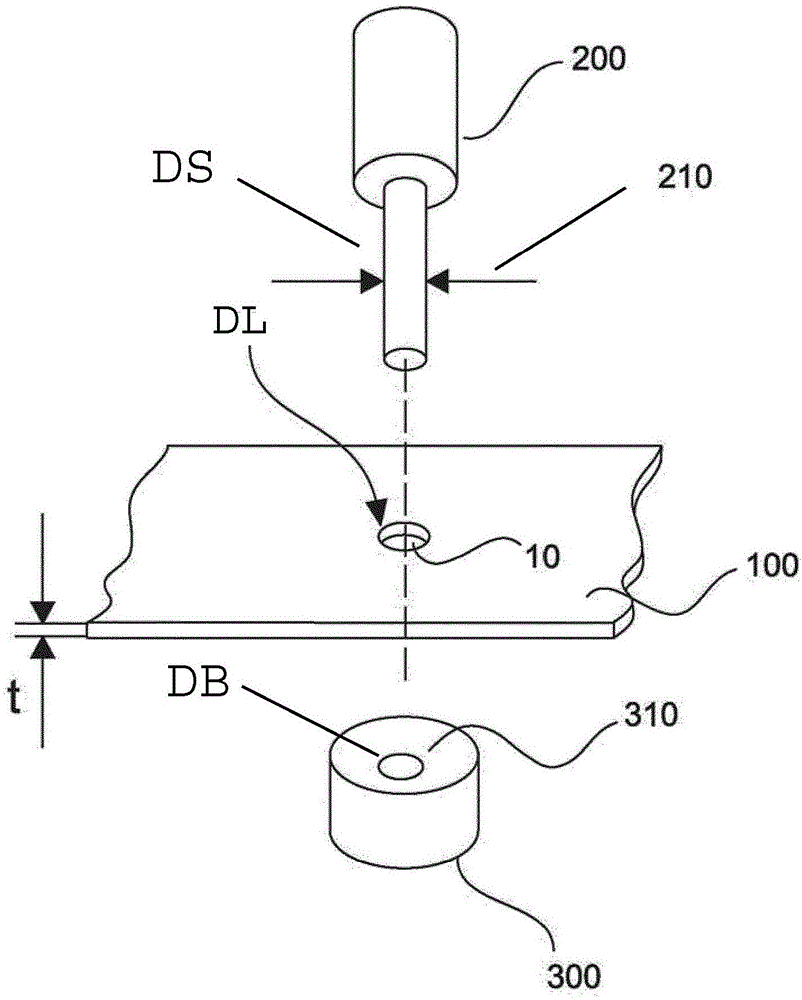

[0024] figure 2 A schematic diagram showing a method for fabricating an acoustic resistance. To produce the acoustic resistance for the damping element, a base material 100 is used and a plurality of holes 10 are punched into the base material. The punching of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com