Composite preparation comprising active-ingredient-containing film coating layer

A technology for composite preparations and active ingredients, which is applied in the field of composite preparations including a film coating layer containing active ingredients, can solve the problems of separation or rupture of the film coating layer, difficulty in ensuring sufficient efficacy of the composite preparation and the quality of commercially available products, and the like, Achieve increased convenience, high marketable product quality, and improved compliance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

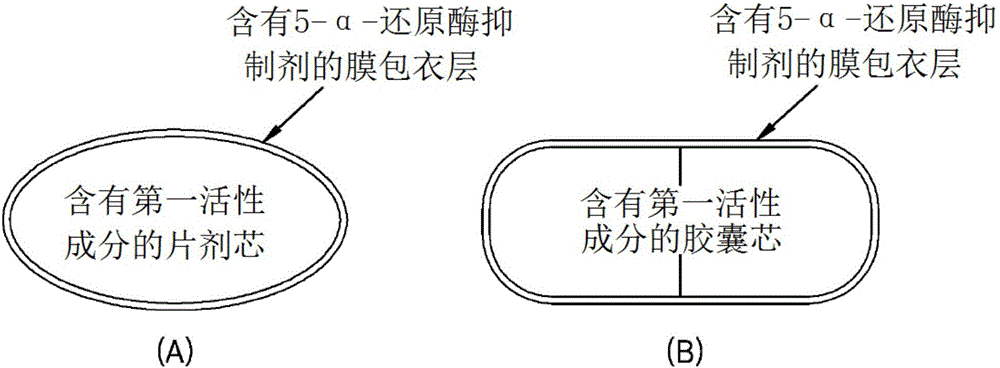

[0090] In the preparation of the core, the core may be any core that can be used as a core in the pharmaceutical field, for example in the form of a tablet, a hard capsule or a soft capsule. However, the embodiments are not limited thereto. In the preparation of the core, any commercially available preparation that can be used as the core can be used, or the core used in the present invention can be directly prepared. The core can be prepared using known techniques in the pharmaceutical field selected by those of ordinary skill in the art depending on the type of core.

[0091] Coating of the core can be performed using any available film coating methods used in the pharmaceutical field, such as pan coating, fluidized bed coating or press coating. However, the embodiments are not limited thereto.

[0092] When the 5-alpha-reductase inhibitor is finasteride (classic 5-alpha-reductase inhibitors known to be teratogenic), a separate independent production line is required to pr...

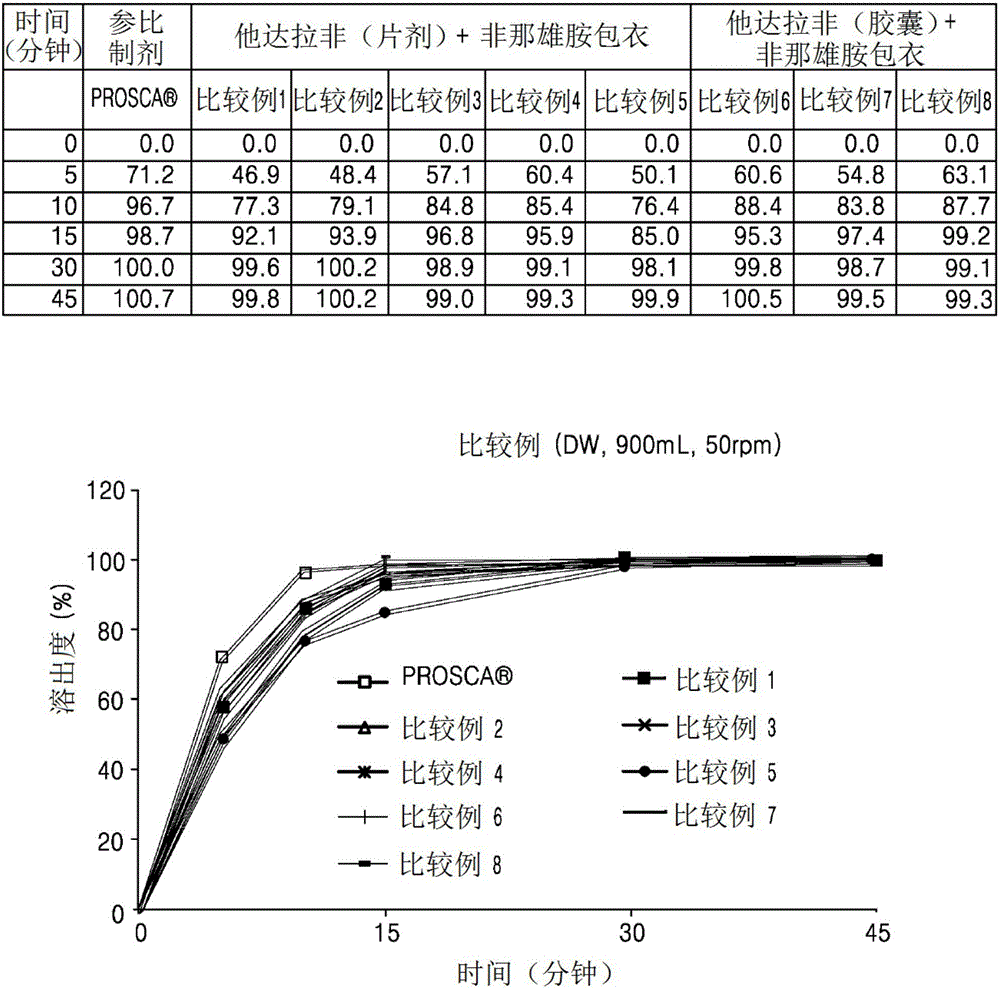

Embodiment 1-10 and comparative example 1-8

[0095] Examples 1-10 and Comparative Examples 1-8: Preparation of Composite Preparations Comprising Finasteride-Containing Film Coating Layers

[0096]Coating solutions were prepared by mixing corresponding coating materials with organic solvent-water mixed solvents at various mixing ratios according to various compositions shown in Tables 1 to 3, and then by using a pan coating machine (SFC-30, available from SejongPharmatech Co., Ltd.) was coated on a tadalafil-containing tablet core (mass of unit dose: 160 mg). Tablet cores containing tadalafil are prepared by mixing tadalafil with mannitol, pregelatinized starch, hydroxypropyl cellulose, sodium lauryl sulfate and sodium starch glycolate, granulating the resulting mixture, and The resulting granules are obtained by tableting. The tablet cores coated with a pan coater were dried at about 35° C. for about 30 minutes, thereby preparing a composite comprising a tadalafil-containing tablet core coated with a finasteride-conta...

Embodiment 12-21

[0133] Examples 12-21: Including tamsulosin hydrochloride coated with a film coating layer containing a 5-alpha-reductase inhibitor Preparation of compound preparation of capsule core

[0134] A coating solution was prepared by mixing coating materials (Examples 12 to 21) having different compositions as shown in Table 7 with an ethanol-water mixed solution (ethanol:water=1:1 (v / v)), Then by using a pan coater (SFC-30, available from Sejong Pharmatech Co., Ltd.) coated on the tamsulosin hydrochloride containing Capsules (available from Hanmi Pharmaceutical Co., Ltd., Korea). The prepared capsules were dried at about 35° C. for about 30 minutes, thereby preparing a composite preparation including a tamsulosin capsule core coated with a film coating layer containing a 5-α-reductase inhibitor.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com