Compositions and methods for delivering tastants

A technology of composition and tastant, applied in the direction of food science, can solve problems such as limited help

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0053] Example 1: Salt composition comprising lactose and fine salt

[0054] Fine salt (74 micron or 200 mesh) was prepared by finely grinding granular salt in a Waring Blender (Waring Blender). Dry mix 100g of lactose with 65g of fine salt. The dry blend was loaded into a benchtop fluid bed coating unit. A binder / coating solution was prepared by dissolving 15g fine salt (44 micron or 325 mesh), 15g 1DE maltodextrin in 150g deionized water. The blend was granulated and coated by top and bottom spray fluidized bed coating. For top spraying, the coating solution is atomized from a top nozzle at a low velocity effective to slowly build up the particles and coat the surface. The feed was varied from 1.5 to 3.0 g / min using a peristaltic pump. The inlet air was 65°C. After all coating / binding solutions were applied, the run was stopped for evaluation. Particle size is controlled by varying the feed rate. Pelletized material may be collected for evaluation. For bottom spray...

example 2

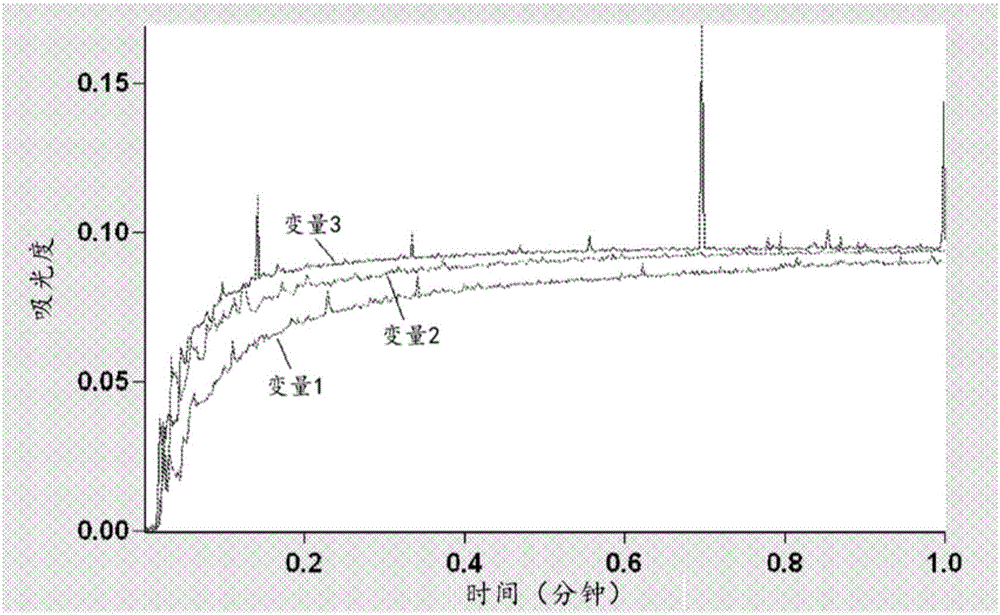

[0056] Example 2: Taste composition comprising 1DE maltodextrin and fine salt

[0057] The same procedure as in Example 1 was followed except that 1DE maltodextrin was used as base / carrier instead of lactose. The rate of particle growth was slower with 1DE maltodextrin than with lactose. Particle size is controlled by varying the feed rate. This feed rate was slower than that in Example 1. The granulated material collected for evaluation exhibited the same characteristics as the granulated salt composition of Example 1.

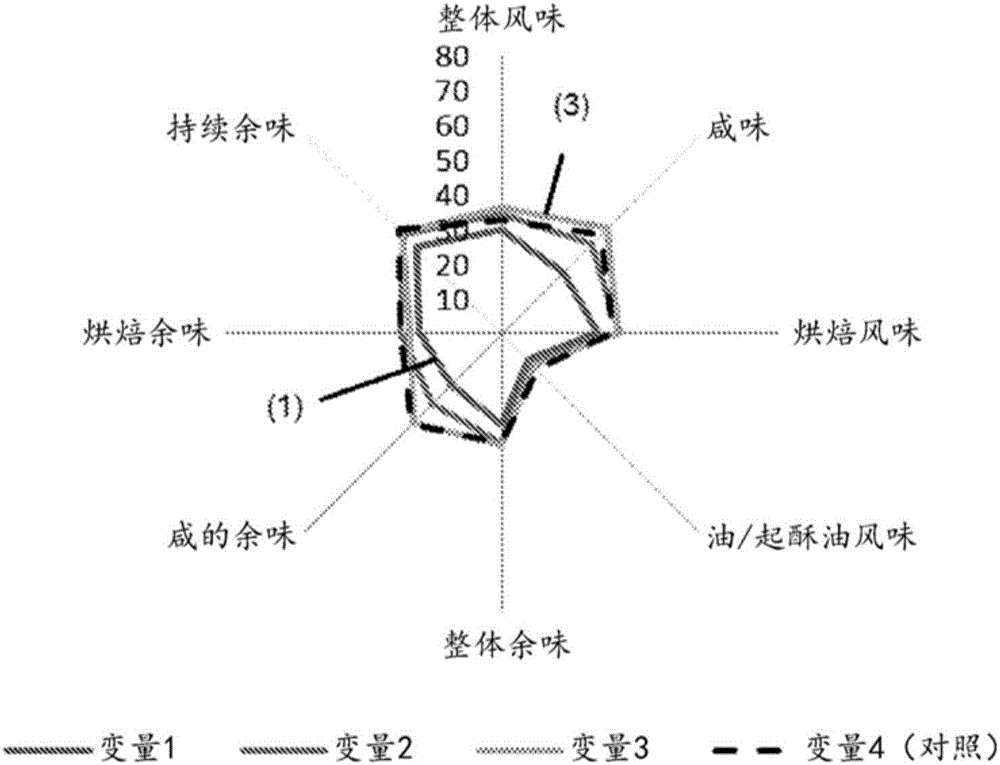

[0058] The visual appearance of the salt composition is characterized by irregularly shaped crystalline pellets resembling granular salt. The strength of the salt composition is very hard and will not crumble during handling. The taste of the salt composition is a salty taste, very pure, without off-flavor, with a very slight sweetness. The bake stability of the salt composition is stable and will not melt, brown or burn when baked on soda crackers or ...

example 3

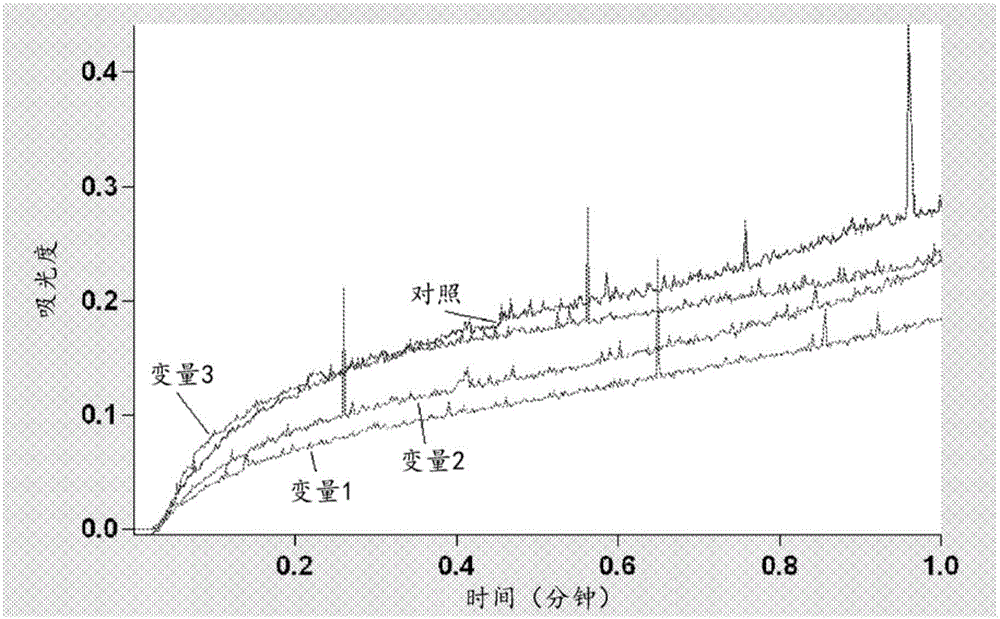

[0059] Example 3: Taste compositions comprising high DE maltodextrin and fine salt

[0060] The same procedure as in Example 2 was followed except that high 20DE maltodextrin was used as the base / carrier instead of 1DE maltodextrin. The salt composition has a distinctly sweet taste. The salt composition is not stable when baked. When baked, the salt composition melts completely and apparently browns to some extent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Average particle size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com