Multifunctional cooking device

A cooking device and multi-functional technology, applied in the field of kitchen appliances, can solve the problems of lower consumer acceptance and insufficient applicability of electromagnetic heating devices, and achieve the effects of ensuring electromagnetic heating efficiency, improving utilization rate, and avoiding falling off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

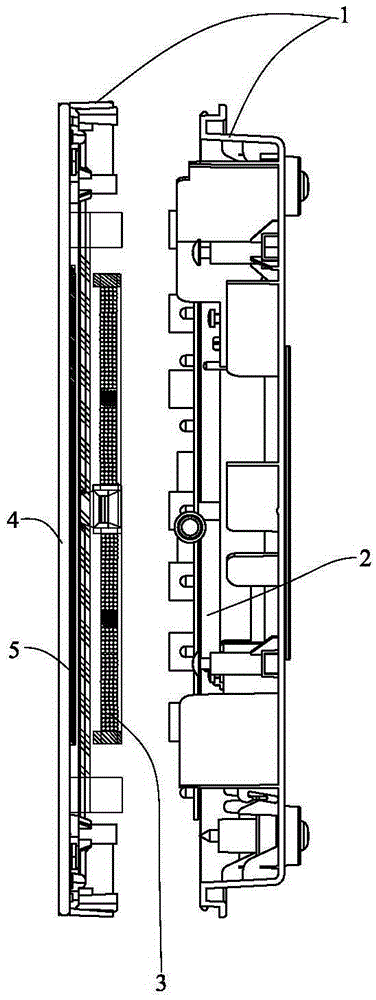

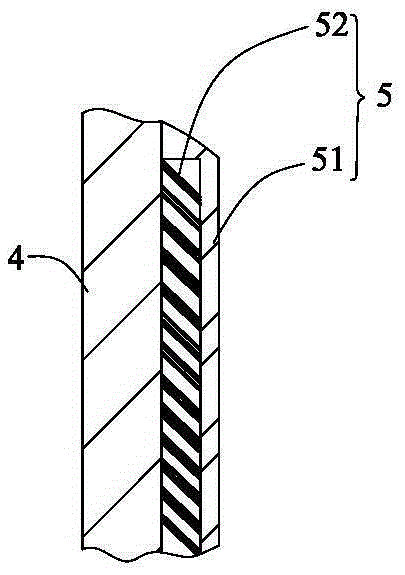

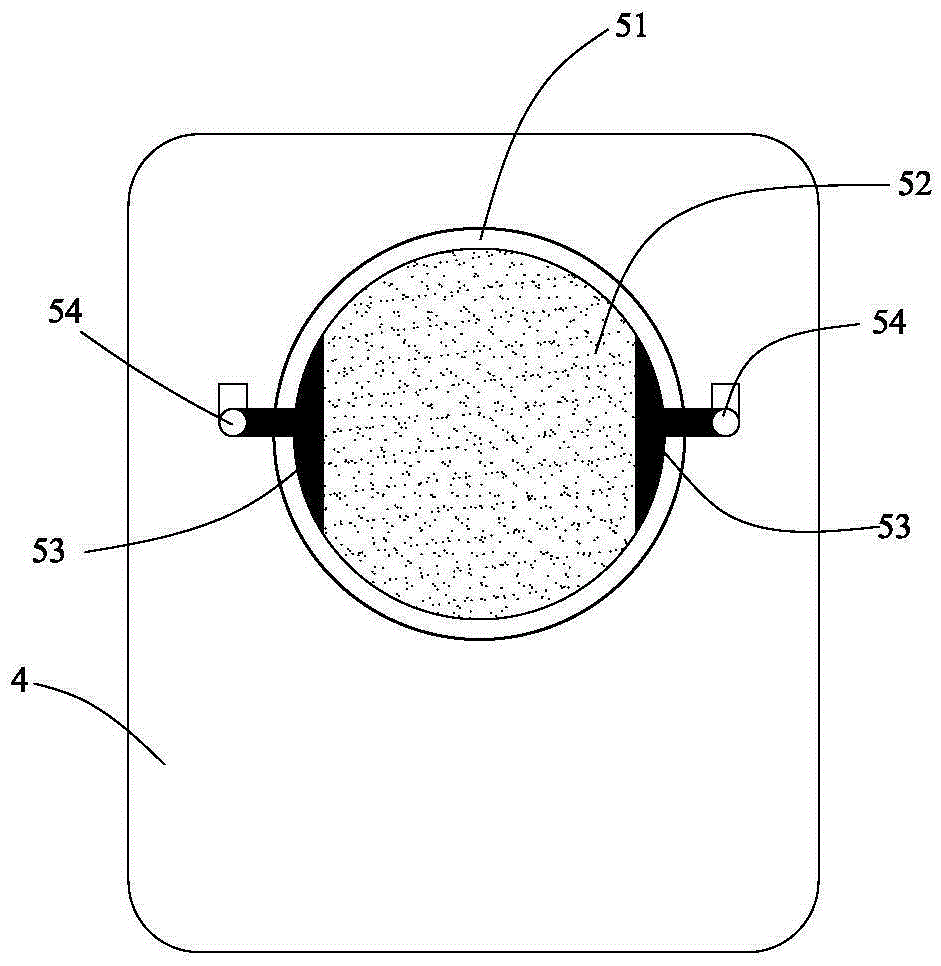

[0033] see figure 1 , figure 2 Shown is the first embodiment of a multifunctional cooking device of the present invention, which is an induction cooker, including a housing 1, a control circuit board 2 located in the housing 1, and a magnetic wire reel 3, and the electromagnetic wire reel 3 is electrically connected to the control circuit board 2. The control circuit board includes a pot detection unit (not shown) and a heating control unit (not shown). The housing is provided with a panel 4 for heat penetration, and the panel 4 is provided with a non-metallic electric heating film 5, the electric heating film 5 is set corresponding to the heating area of the electromagnetic coil 3, and the electric heating film 5 is electrically heated. Connected to the control circuit board, the heating control unit controls the electric heating film 5 and the electromagnetic coil 3 to work independently of each other according to the signal of the pan detection unit.

[0034] In this e...

Embodiment approach 2

[0048] see Figure 5 The shown second embodiment of a multifunctional cooking device of the present invention is different from the first embodiment in that: a heat insulating layer 6 is provided between the electric heating film 5 and the electromagnetic wire disk 3 . Effectively avoid mutual heat radiation between the electric heating film 5 and the electromagnetic coil 3, greatly improving reliability and lifespan. And greatly improve the heating energy efficiency.

[0049] In this embodiment, the heat insulation layer 6 is arranged inside the panel 4 together with the electric heating film 5 , covers the outside of the insulating layer 51 of the electric heating film 5 , and seals the electric heating film inside. In this way, internal space can be saved.

[0050] In this embodiment, the heat insulation layer 6 is made of asbestos or asbestos mixture or mica material with high temperature heat insulation effect.

[0051] As an improvement, a first heat dissipation gap i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com