Moving mass center adjusting electromechanical actuator

An electromechanical actuator and variable center of mass technology, which is applied in the direction of electromechanical devices, electric components, electrical components, etc., can solve the problems of reducing system stiffness and transmission efficiency, cumbersome and redundant electric actuator structure, and reducing system reliability. Achieve the effects of avoiding relative displacement movement, improving dynamic response capability, and reducing volume and weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

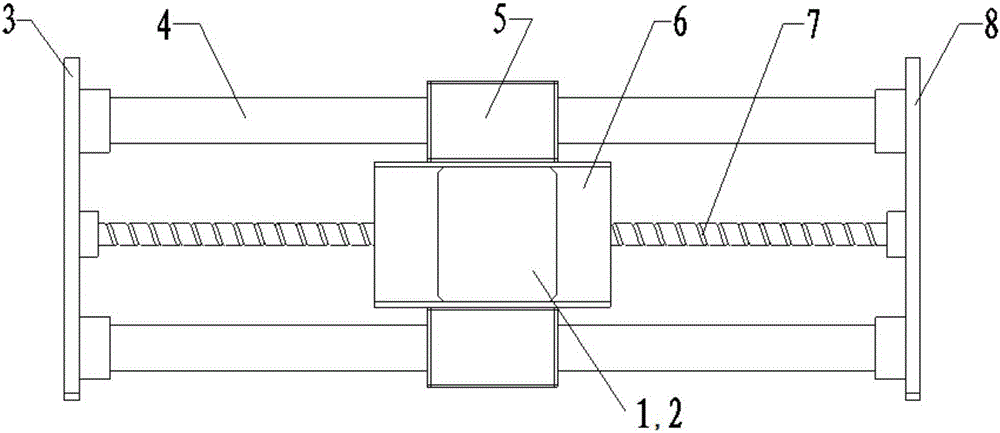

[0022] Such as figure 1 As shown, an electromechanical actuator for variable center of mass adjustment provided by the present invention includes a servo battery 1, a control driver 2, a front baffle 3, a guide rail 4, a guide support structure 5, a servo motor 6, and a ball wire Rod pair 7 and tailgate 8, front fence 3, tailgate 8 are respectively fixed on the two ends of two guide rails 4 and a ball screw pair 7. The two guide rails 4 and the ball screw pair 7 are parallel to each other, the ball screw pair 7 is located in the middle of the two guide rails 4, and between the two guide rails 4, the ball screw pair 7 and the front baffle 3 and the rear baffle 8 Both are fixedly connected by lock nuts. The bottom of the servo motor 6 is located on the guide support structure 5, and the two are fixedly connected by bolts. The bottom of the gui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com