Electrical conduit connecting bend

A technology of electrical bushings and connecting elbows, applied in the direction of cable joints, etc., can solve the problems of wire insulator damage, inability to adjust, unfavorable protection of wire insulators, etc., to reduce stress, improve protection, and increase buffering effects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

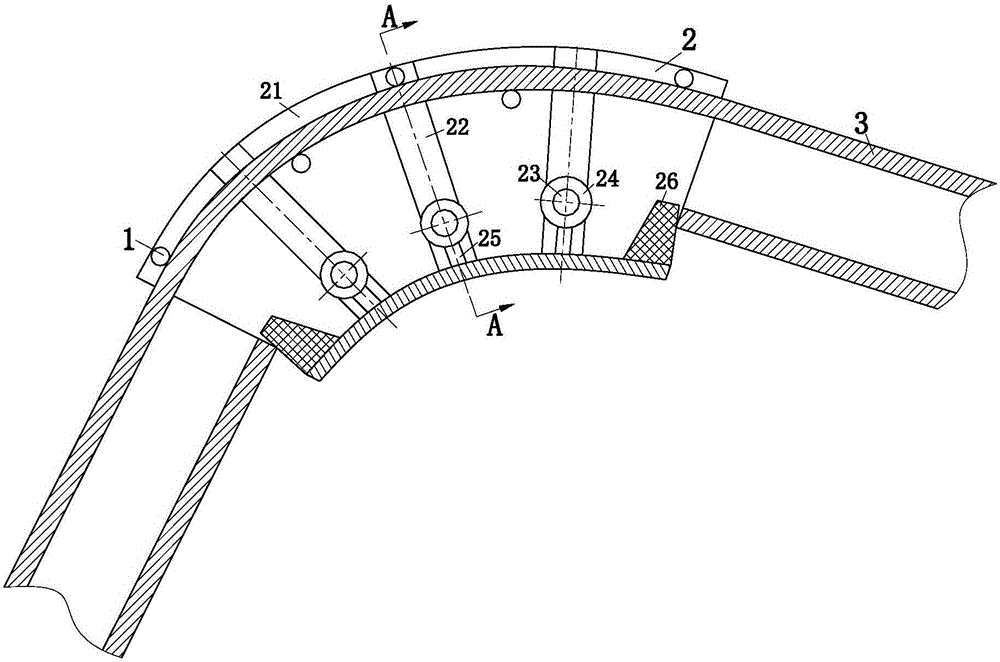

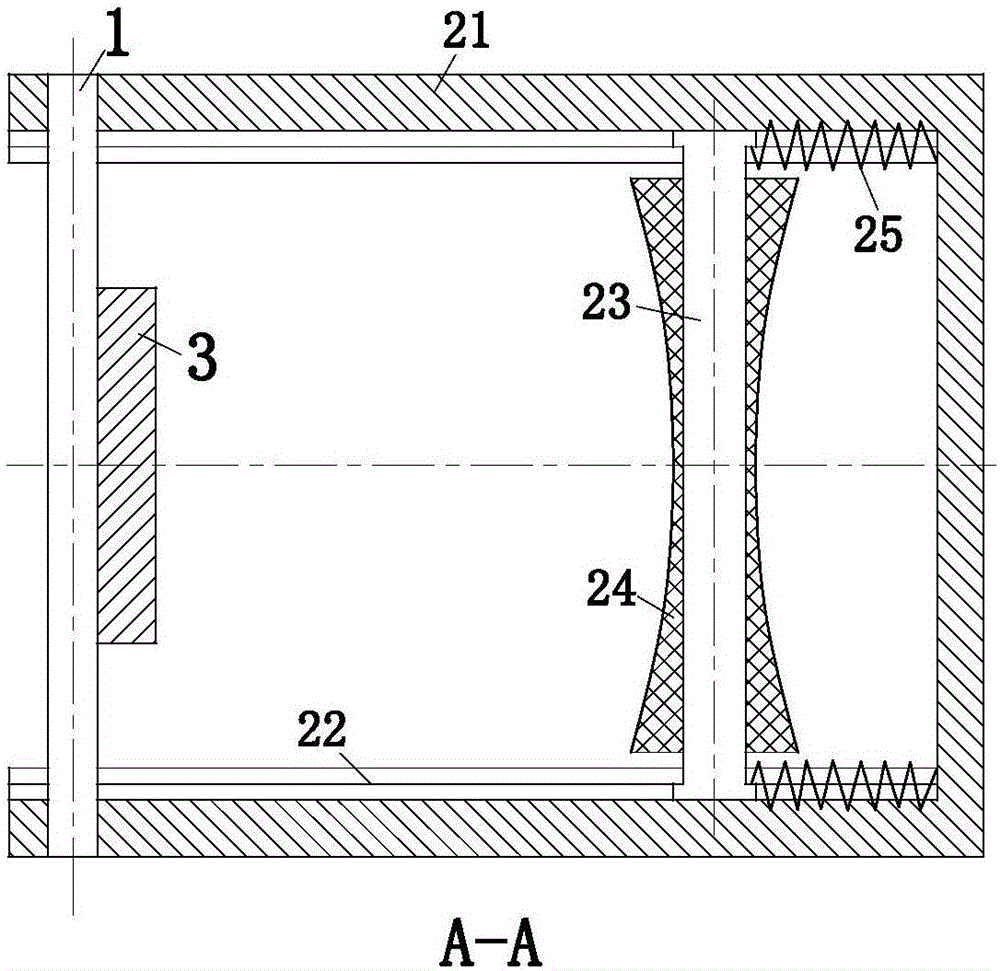

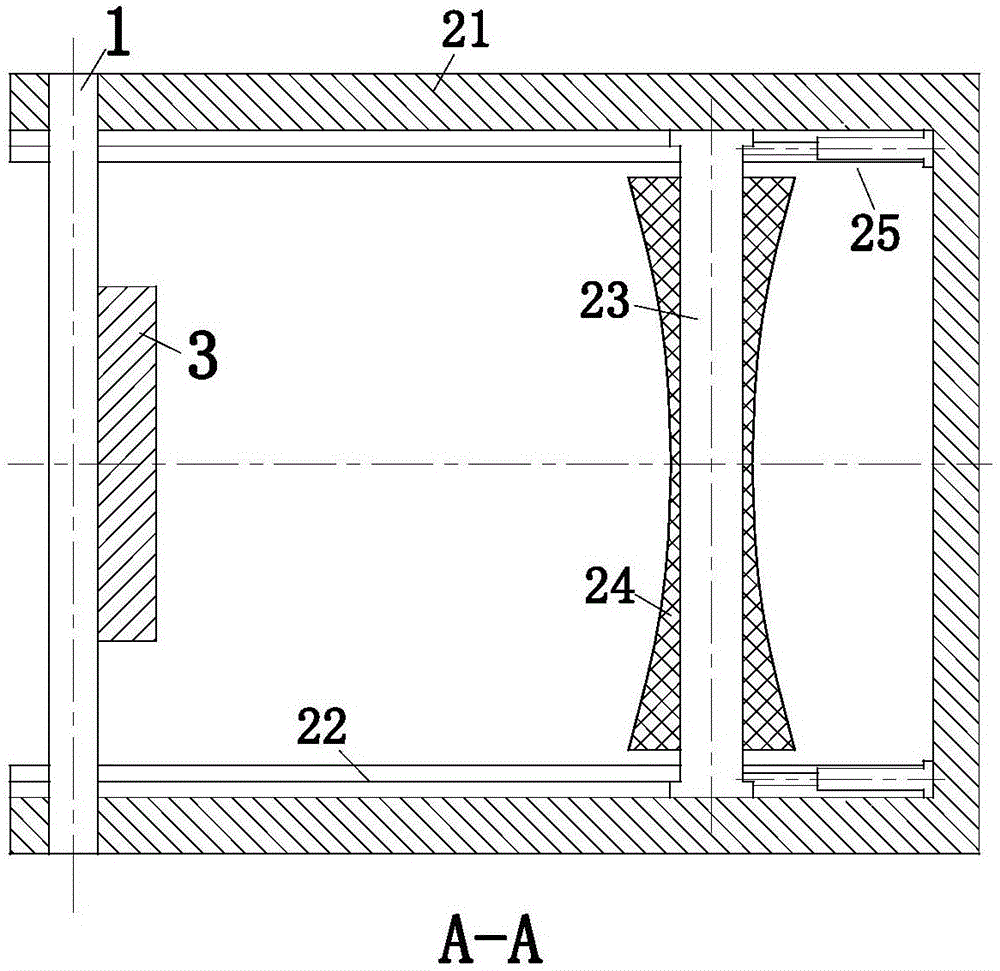

[0023] Such as Figure 1 to Figure 4 As shown, an electrical bushing connection elbow according to the present invention includes a positioning unit 1 and a joint unit 2, the joint unit 2 is connected to the electrical bushing 3, and the connection between the electrical bushing 3 and the joint unit 2 The positioning unit 1 is used for positioning. The connecting unit 2 is mainly used to protect the wires at the joint of the electrical bushing. The positioning unit 1 is used to fix the position of the connecting unit 2 and the electrical bushing 3, thereby facilitating the pairing of the connecting unit 3. The electric wires in the electrical sleeve 3 produce protection.

[0024] Such as Figure 1 to Figure 4 As shown, a kind of electrical bushi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com