High-beam-quality large-scale VCSEL in-phase coupled array

A coupling array and high-beam technology, which is applied to lasers, laser components, semiconductor lasers, etc., can solve the problems of high cost and achieve the effects of low cost, high beam quality, and easy promotion and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

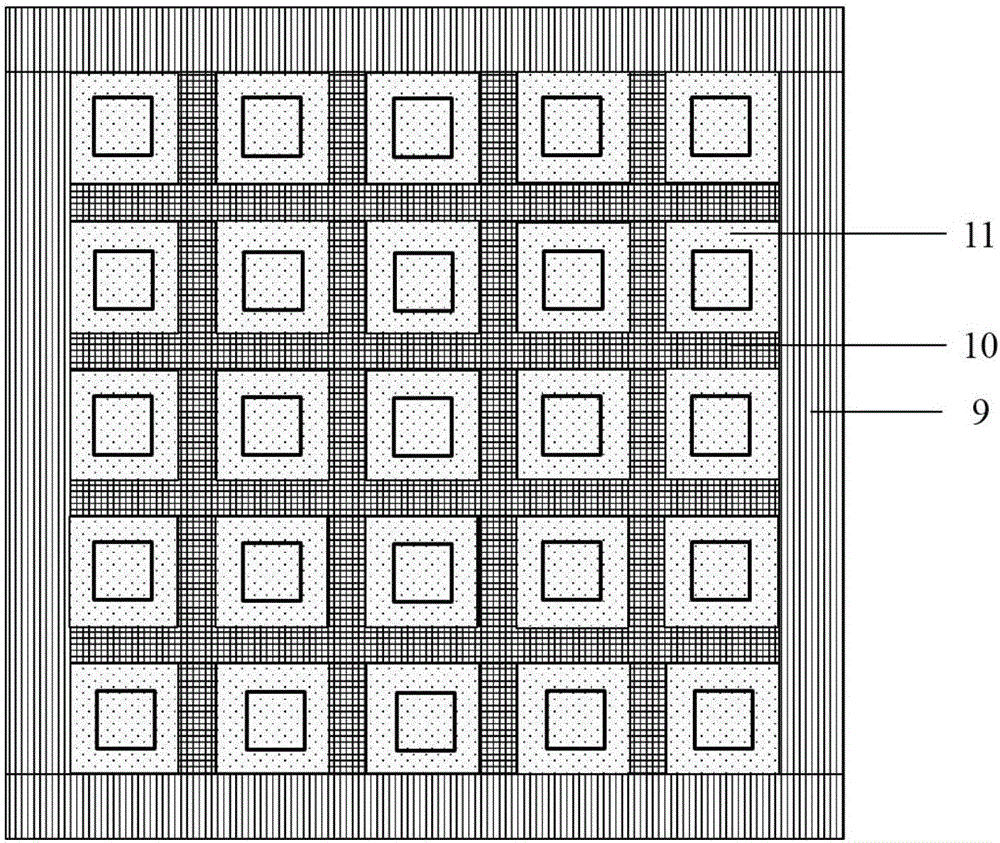

Image

Examples

Embodiment Construction

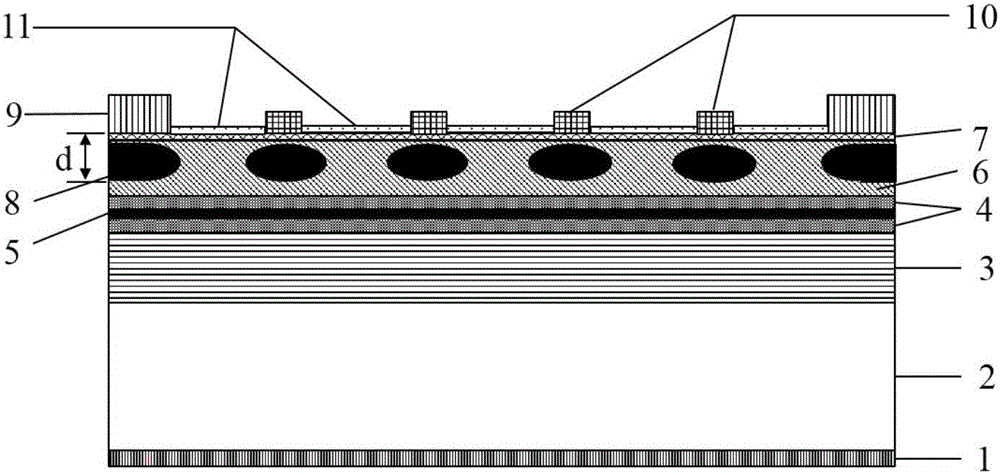

[0028] Combine below Figure 4-Figure 12 The specific implementation methods of the preparation method of large-scale VCSEL in-phase coupling array with high beam quality are introduced respectively;

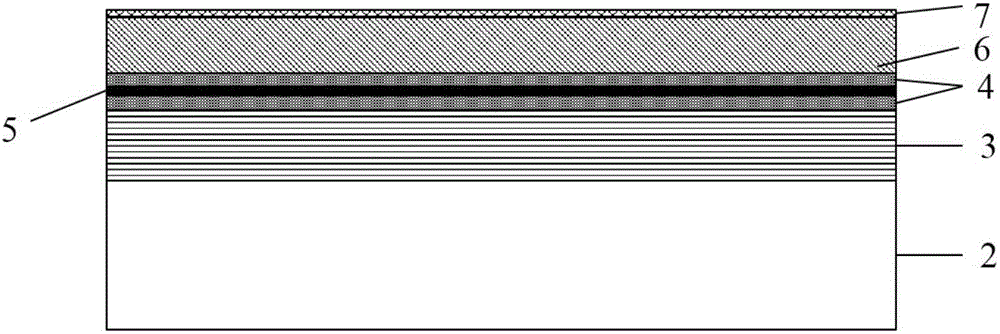

[0029] Step 1. Using metal-organic chemical vapor deposition (MOCVD) to sequentially epitaxially grow thirty-four pairs of n-Al on N-GaAs (0.12-0.9) GaAs and n-Al 0.9 GaAs forms the DBR mirror, Al (0.12-0.9) GaAs / Al 0.9 GaAs lower confinement layer, three pairs of Al 0.3 GaAs / GaAs quantum well structure active region, Al 0.9 GaAs / Al (0.12-0.9) GaAs upper confinement layer, 22.5 to p-Al 0.12 GaAs and p-Al (0.9-0.12) GaAs forms the DBR mirror, p-Al 0.12 GaAs and p-GaAs heavily doped contact layers;

[0030] Step 2, using plasma-enhanced chemical vapor deposition (PECVD) to grow a layer of 3.2 μm silicon dioxide on the surface of the epitaxial wafer obtained above;

[0031] Step 3. Use reverse glue to do photolithography and sputtering process to sputter a layer of silico...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com