led display control system

A technology of LED display and control system, applied in static indicators, instruments, etc., can solve the problems of limited RGB data set, difficult TTL signal, difficult LED display testing, etc., to improve refresh rate and grayscale, shorten development Period, the effect of improving the display effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

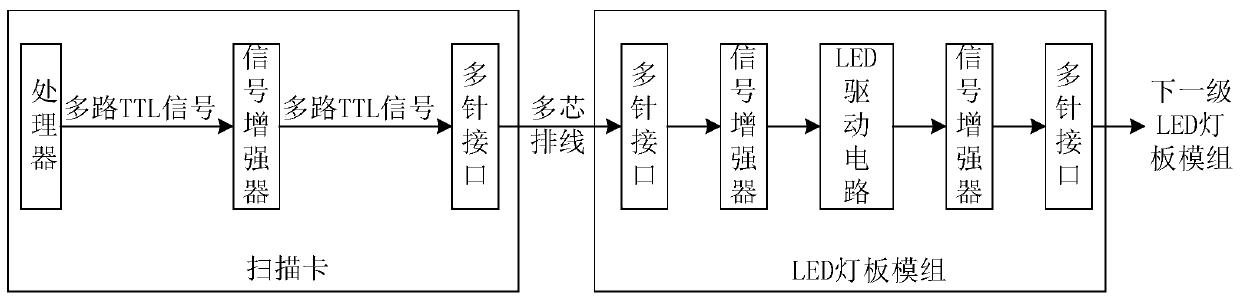

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

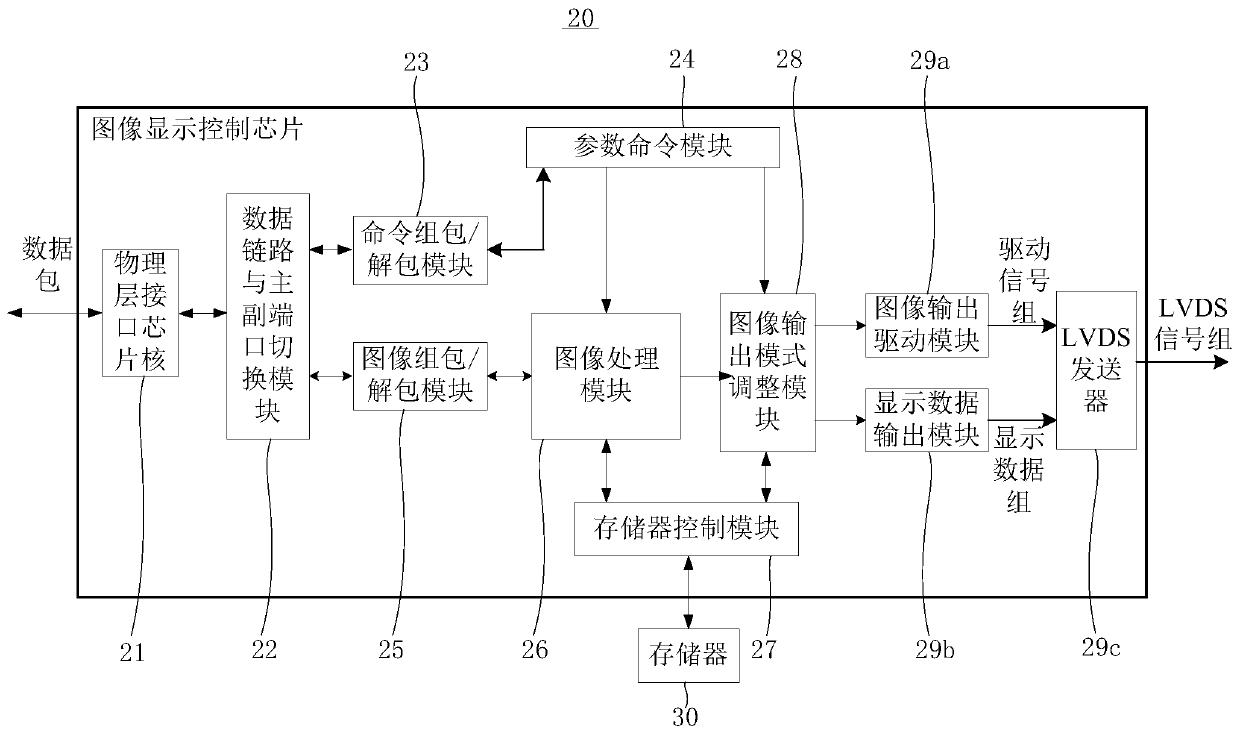

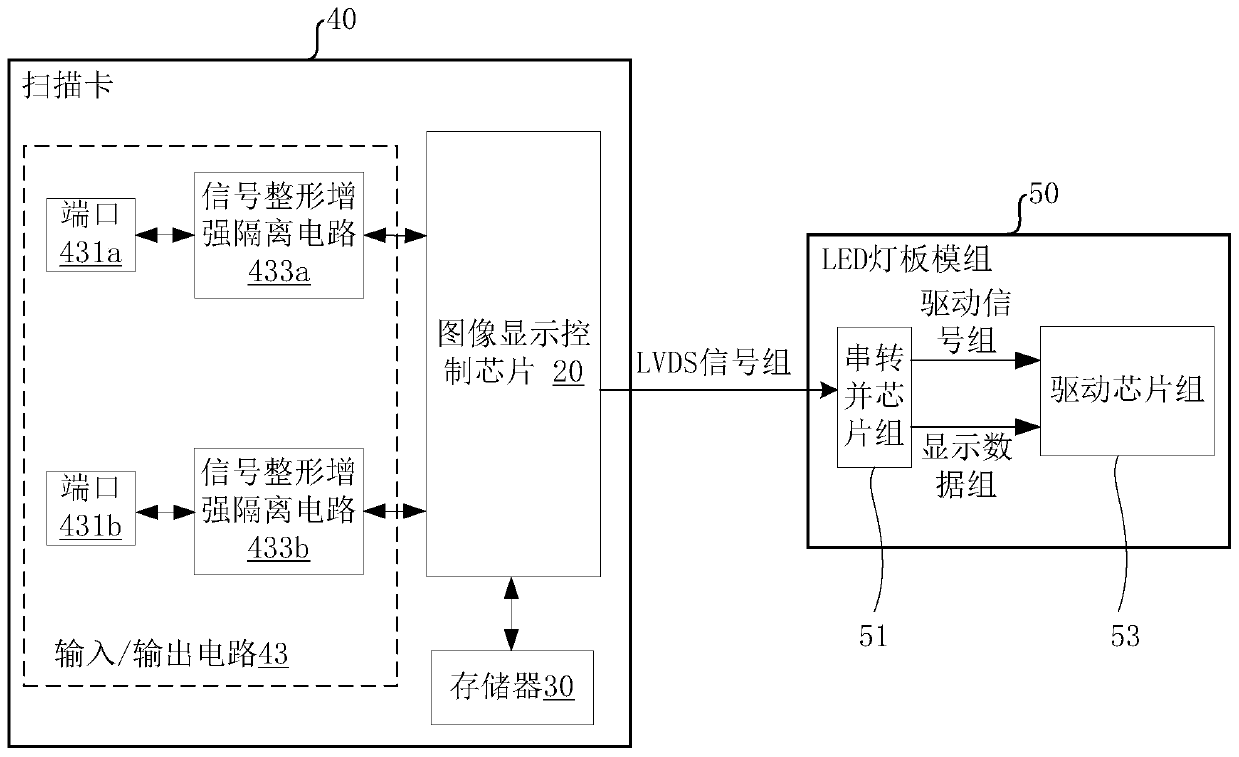

[0025] In order to make the above-mentioned objects, features and advantages of the present invention more obvious and understandable, the specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

[0026] Specifically, the following embodiments of the present invention propose a new LED display control system technical solution, which makes the scanning card function as chip as possible, in order to reduce the size of the scanning card, support large loading, and support high-density small-pitch screens. At the same time, it solves the problem of poor display effect of the existing scanning card in the general-purpose driver chip screen body, and improves the display effect of the LED display; and through the use of new transmission methods, it can reduce the number of cable cores and improve transmission Stability and reliability, reduce EMI, and meet EMC requirements more easily.

[0027] See figure 2 , Which is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com